U.S.-based silicon-to-solar-module supply chain is on the way

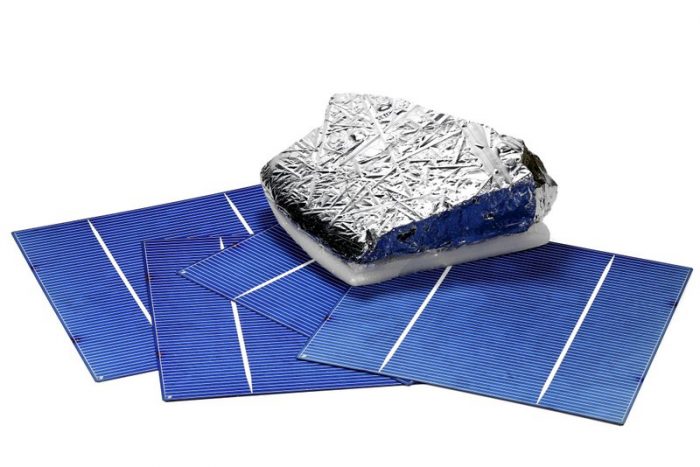

With the Inflation Reduction Act now established, attention turns to broader development of a domestic solar PV supply chain. The U.S. has its share of solar module manufacturers, but the raw materials — from silicon to polysilicon to wafers and ingots — are still sourced overseas. Can that start to change?

Maybe! The first signs of life come via Mississippi Silicon LLC — the first new silicon metal facility in North America in 40 years — which has announced plans to work with REC Silicon to help establish a low-carbon and fully traceable U.S.-based solar supply chain. The companies have signed a memorandum of understanding (MOU) committing them to negotiate a raw material supply agreement.

“Mississippi Silicon was founded nearly ten years ago to be a domestic source of high-quality silicon metal to the U.S. solar, electronics and chemical industries,” stated Eddie Boardwine, CEO of Mississippi Silicon. “We are pleased by the growing recognition of the importance of a strong end-to-end US supply chain for these materials. Passage of the SEMA Act is critical to bringing that supply chain to reality.”

REC is a producer of high-purity electronics and solar grade polysilicon with assets in Moses Lake, Washington and Butte, Montana. Recent investment by the Hanwha Group into REC Silicon, in conjunction with Hanwha’s subsidiary Qcells, moves REC to expand its relationship with Mississippi Silicon to support the development of an end-to-end U.S. solar supply chain from silicon metal and polysilicon to fully assembled solar modules.

The plan follows the August 18 passage of the Solar Energy Manufacturing for America Act (SEMA) as part of the Inflation Reduction Act, expanding U.S. production of polysilicon and metallurgical grade silicon.

Located in the northeast corner of Mississippi State, the plant is strategically placed to take advantage of a growing domestic customer base, stable low-cost electricity, and a regional supply chain.

The recent Hanwha investment is enabling a re-start of the currently idle Moses Lake plant in 2023 and will make available high volumes of low-carbon solar grade polysilicon. REC shut down the Moses Lake plant in 2019 due to unfavorable global market conditions.

Comments are closed here.