Solar Rooftop Mounting Buyer’s Guide 2021

The most finely tuned components of rooftop solar PV systems are the structural systems and attachments. Industry-standard products have found ways to improve. Niche brands have broadened their lineup to become more versatile. Whatever your installation preference, the market is meeting your needs and generally making life easier. This Buyer’s Guide is a snapshot of the rooftop mounting and racking products offered by the leading brands in the residential and commercial and industrial (C&I) space. Click on each product listed to expand for more information.

UPDATE: The 2022 Rooftop Mounting Buyer’s Guide is now available

Roof Tech

Headquartered in Southern California, Roof Tech US has national sales teams in place to provide superior service to installers and solar panel distributors throughout North America. Roof Tech has been a pioneer of waterproof flexible flashing since 1994. Its legacy is linked directly to Yanegiken Technology and Research Institute, its parent company in Japan, founded in 1968 to conduct research and develop new roofing technologies. Roof Tech’s self-flashing solar mounts such as the RT-APEX and the RT-MINI are known for their efficiency and fast installations.

RT-PLUS

Components included: base, screw, flashing

Tools needed: Hex driver

Advantages:

- AlphaSeal® self-flashing system

- Operating temperature from -40F to 248F

- No Caulking or Pre-Drilling Required

- Universal Attachment to Any Slope

- Metal, EPDM, TPO, SBS, & Asphalt compatible

- 5 Round mounting holes for deck attachment (OSB or Plywood)

- 2 Square holes for rafter attachment

- Available in black and mill finishes

- Rail mounting slot for 3/8” and 5/16” bolts

How does it install: The RT-PLUS is a combination of our best seller, the RT-MINI II base, PLUS an integrated L-foot. Designed for ultimate versatility and durability, our new mounting system can be fastened directly to rafters or decks (OSB and plywood only), ensuring a secure and efficient installation.

Certifications: UL2703A pending

RT-APEX (rail-less)

Number of pieces: Three to eleven based on configuration.

Tools needed: Six

Certifications: UL 2703,441, ICC ESR 3575, TAS 100, ASTM 2140,1970, HVHZ Certified

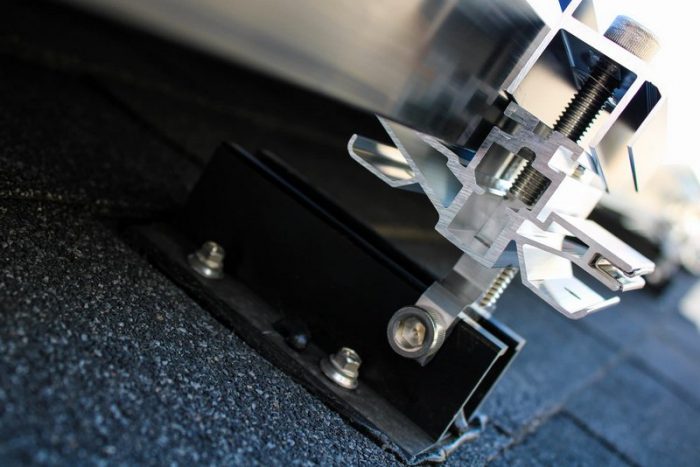

Installation: The RT-APEX fastens to rafters or direct to the roof deck (7/16 OSB minimum) or a combination of both. Chalk lines are needed to plot the location of the bases. When fastened to a rafter, it uses five mm diameter mounting screws, eliminating the need for a pilot hole and caulking. The RT-APEX features slide-in mounting and one-step leveling to adjust and level the panels. The universal clamping feature helps to fit module thicknesses ranging from 30 to 46mm. This advanced rail-less racking system adjusts to fit over forty different PV module manufacturers' solar panels. Roof Tech's solar mounts are self-sealing with engineered integrated AlphaSeal, creating a waterproof mounting system.

Advantages: The rail-less RT-APEX is faster to install without the use of rails. It also provides less weight on your residential roof to uphold the structure's integrity. Without the use of rails, there is more room for flexibility, and design helps improve the ascetics of the roof. Rail-less, deck-attached installs take half the time of traditional rafter-mounted rails with metal flashing than with the RT-APEX with flexible flashing. Design your build with the RT-APEX span calculator for free by registering here.

RT-MINI II

Number of pieces: Two

Tools needed: Five

Certifications: UL 2703,441, ICC ESR 3575, TAS 100, ASTM 2140,1970, HVHZ Certified

Installation: The RT-MINI II has more options for installing rafters and handling thicker insulation on low-slope roofs. It comes with an option of two 90 mm screws to offset rafter mounting, allowing for more attachment options on any style of roof and pitch. Design your build with the newly featured RT-MINI II span calculator.

Advantages: The RT-MINI II is a universal attachment for railed systems designed to be agnostic to any roof type and roof pitch engineered to withstand wind speeds up to 180 mph and ground snow up to 90 psf. The main difference between RT-MINI II and conventional flashing is the faster installation time because RT-MINI II is fastened with wood screws, eliminating the need for pilot holes and caulking. As a result, there is no damage to the seal on asphalt shingles, so the roof warranty remains intact.

RT-CONDUIT MOUNT

Residential or C&I? Residential

Components included: RT-CONDUIT MOUNT with AlphaSeal® System (RT-Butyl + RT Screw)

Tools needed: 5/16” or 8mm hex socket.

Certifications: International Code Council

How does it install: RT-CONDUIT MOUNT featuring a double flexible flashing system. By pressing the top with a thumb, the installer feels the location for the mounting screws. Once the conduit position is laid out by either a chalk line or from the conduit secured between two points, adding the RT-CM’s along the way is an easier process. Both direct to deck (OSB or Plywood) or rafter attachment (with the optional 5x90mm RT Screw).

Advantages: It features AlphaSeal, Roof Tech’s flashing system certified by the ICC (International Code Council). Designed with a height (top of roof to bottom of conduit) that avoids derating the ampacity of the conduit (NEC), it allows for either a cowboy clamp (close conduit pipe clamp) or half-moon (conduit strap) conduit clamps ranging from ½” to 1” dia. conduit. The clamps are not included, since it is common item carried by all contractors used on other parts of the array assembly. It is packaged 20ea per box (RT 5x60 mm screws included). Each box measures 3 x 4 x 12 inches and weighs 3.7 Lbs. It also has a sleek, black design that leaves a more aesthetically pleasing end result.

Distributor’s list | Website | Email | Webinar

DynoRaxx

DynoRaxx has been selling professional solar racking equipment since 2009. It is the only solar racking manufacturer that uses fiberglass as the racking material for its flat-roof ballasted solution, and the main advantage is it’s a tool-less system that reduces labor installation times.

C&I flat roofs: DynoRaxx Evolution FR

Number of pieces: 3

Tools needed: none, 100% tool-less

Certifications: UL 467, UL 2703

Installation: The DynoRaxx Evolution FR is easy to transport, stage, and install. Installation does not require any tools to assemble resulting into major labor savings.

Advantages: Since the racking only consists of three major parts and are compatible with every framed commercial solar module on the market without any special ordering or lead times. You receive the right product for the job every time.

DynoBond

Number of pieces: 1, various lengths available (8”, 12”, 38”, 50”, 76”, 96”)

Tools needed: None

Certifications: UL 467 & UL 2703

Installation: The DynoBond is used to ground solar modules within the array. It’s a tin platted copper wiring with factory crimped stainless steel connectors that ground the modules.

Advantages: The DynoBond can be used to ground solar modules in applications for residential, commercial, industrial, and utility scaled projects. The product is used by DynoRaxx for the ballasted solution and also many racking competitors are using it for their grounding needs as well.

QuickBOLT

QuickBOLT is a family-owned and operated business that works hard to solve your problems. They believe solar mounting can be easier and more affordable for everyone. QuickBOLT supplies one of the widest ranges of innovative solar mounts for residential and commercial roofs in the US market. They are most known for their patented Microflashing and BoltSeal powered mounting solutions, and have been working with installers for nearly a decade to make solar installation easier than ever before.

Split Top Butyl Bottom Deck Mount

Components included: 1 butyl-backed Split-Top T-Foot, 4 - 5/16" x 2 1/2" stainless steel hex lag Screws with Sealing Washers. PN #16334

Tools needed: ½” Nut Setter. Recommended PN# 17655.

Advantages: The Split-Top Butyl Deck Mount is designed for fast and leak-proof installations on Asphalt, EPDM, and TPO roofs. This mount offers versatility, allowing you to mount anywhere on the roof deck. The T-Foot features a split top for use with open channel rail utilizing Saddle Mounts or for dropping in rail. The butyl base ensures superior water protection and quick placement, while the stainless-steel T-foot provides easy leveling and rail adjustment. Each mount comes with 4 screws with pre-assembled sealing washers for a secure fit. The pullout ratings keep your array secure: 1310 lbs deck-mounted or 3,228 lbs rafter-mounted.

How does it install: Install anywhere on the roof. No need to locate rafters. Place T-Foot on the roof and press firmly into place. Insert all 4 hex lags and drive the screws until the umbrella washers are compressed. (To Drive Screws and Set Umbrella Washers Properly Torque PSI should not Exceed 57 lbs/Inch). The Split-Top Butyl Deck Mount works on Asphalt, TPO and EPDM roofs.

Certifications: UL Recognized Components, Miami-Dade Approved, PE Tested

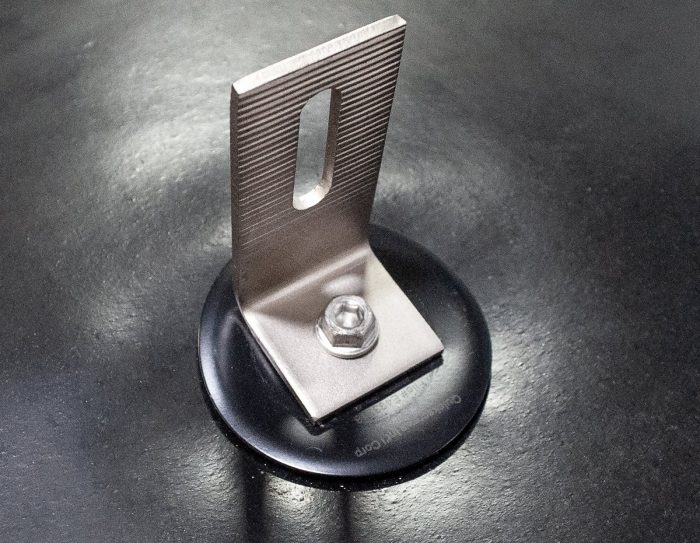

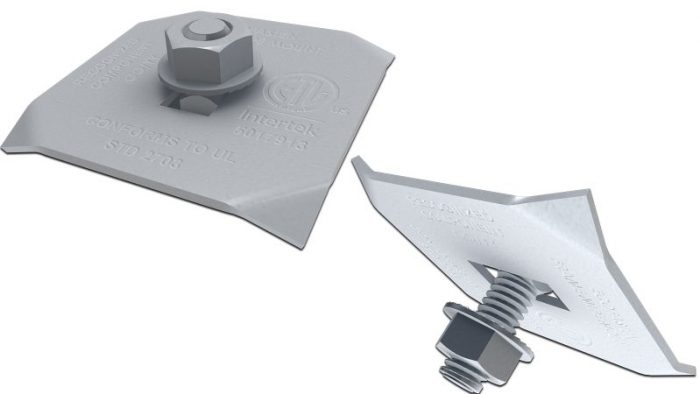

QB2 with Microflashing

Components Included: 1 3” Microflashing®, 1 QB2 Bolt, 1 L-Foot. PN #17662, 17862

Tools Needed: 1/2" Nut Setter or 6MM Hex Driver. Recommended PN# 17655. Sealant (optional)

Certifications: UL Recognized Components, Miami-Dade and Florida Approved, PE Tested

How does it install: Place the Microflashing over the shingle. Drive the patented Dual Drive Shoulder Screw through the rafter until the L-Foot is fully secured. You will know it is secure when you see the Microflashing mechanically compression-sealed to the roof. We call this technology: BoltSeal. Intertek Lab ASTM testing confirms that QB2 can be installed without sealant. QB2 works on Asphalt Shingle, TPO, and EPDM roofs.

Advantages: QB2 only has 3 components and can be installed in less than 30 seconds. Unlike bulky sheets of flashing, Microflashing is installed without lifting shingles or removing nails. QuickBOLT is the only Top Mount in the industry that uses BoltSeal technology, which allows QB2 to be mounted on a variety of asphalt shingle, EPDM, and TPO roofs that other flashing cannot. During seasonal weather changes that may cause expansion and contraction on the rooftop, the Stainless-Steel L-Feet have the flection capacity to move with the solar array.

The Throne

Components included: L-Feet, Set Screws, and Grip Plate

Tools needed: Torque Wrench or Hex Key (for M10x25mm Set Screws)

Certifications: UL Recognized Components, PE Tested

How does it install: Place The Throne over metal roof seam and tighten Set Screws.

Advantages: The Throne speeds up install time significantly with pre-assembled parts, ready to place and tighten. Simply your install and reduce unnecessary steps on the roof. The mount includes a Grip Plate with cross-knurling that provides extra grip, enhances pull-out resistance, and protects the roof.

Height Adjustable All Tile Hook - for Side Mount Rails

Components included: 1 hook, 2 screws. PN #17587, 17589, 17593

Tools needed: Recommended: Drill bit, #15433 or 15437 Hex Driver, Sealant compatible with roofing materials

How does it install: Remove the tiles from the install area. Locate and mark the rafters. Place the mount and predrill the holes. Fill the predrilled holes with sealant. Drive the mounting screws to secure the mount and place the tiles back over the mount.

Advantages: QuickBOLT’s versatile All Tile Roof Mounts work on Flat or Curved tile roofs. The wide range of adjustability and leverage points ensure that you can use these mounts with any tile roofing style and work around inconveniently located rafters.

Conduit Puck Kit

Components included: 1 EPDM Cylinder, 1 Mounting Screw, 1 - 3/4" Clip + Screw. PN# 16323, 16324

Tools needed: Recommended: Impact Driver or Drill and 7/16th”Hex Driver

Application: (in case it has a specific application. Rail or rail-less? Residential or C&I? Certain C&I roof types?)

Material: 2-1/4" EPDM Conduit Mount. Steel Conduit Clip with Zinc Plating

Key feature: The Conduit Puck™ Kit’s low-profile design is ideal for homeowners, providing a sleek look on the roof. Speedy install in 5 seconds or less, no predrilling or sealant required. Skip locating the rafter and attach anywhere on the roof deck. Works on a variety of roof types: Asphalt Shingle, TPO, or EPDM. Uses torque-driven compression to create a watertight seal. Protects the integrity of the roof – no lifting shingles or removing nails and staples.

How does it install? Open the Conduit Clip slightly in order to place screw through base hole. Thread the Mounting Screw with Clip into Puck hole, just enough so it doesn’t fall out. Next, orient Clip to conduit direction. Use 7/16th hex driver to fasten, then thread the bolt through clip’s top hole.

All Stone Coated Steel Hook

Components included: 1 hook, 2 screws. PN# 17640

Tools needed: Recommended: Drill bit, #15433 or 15437 Hex Driver, Sealant compatible with roofing materials

Certifications: UL Recognized Components, PE Tested

Installation: Remove the metal roof tile. Locate and mark the rafters. Place the mount and predrill the holes. Fill the predrilled holes with sealant. Place mount over lower roof tile, drive mounting screws to secure the mount and place roofing panels back over the mount.

Advantages: The wide base allows for more range when bolting to the roof rafter and the 3 points of attachment for the arm allows you to move the arm according to the location of the barrel on curved profile models. Works on direct to deck and batten systems.

QB2 with Microflashing (C&I)

Components Included: 1 3” Microflashing®, 1 QB2 Bolt, 1 L-Foot. PN #17662, 17862

Tools Needed: 1/2" Nut Setter or 6MM Hex Driver. Recommended PN# 17655. Sealant (optional)

Certifications: UL Recognized Components, Miami-Dade and Florida Approved, PE Tested

How does it install: Place the Microflashing. Drive the patented Dual Drive Shoulder Screw through the rafter until the L-Foot is fully secured. You will know it is secure when you see the Microflashing mechanically compression-sealed to the roof. Intertek Lab ASTM testing confirms that QB2 can be installed without sealant.

Advantages: QB2 works on more than just Asphalt Shingle. Install QB2 directly to TPO and EPDM roofs using the same simple steps that save you time and money on your installations. QuickBOLT’s patented BoltSeal technology is so powerful that you don’t need to rely on chemical sealant to keep water out, saving you an extra step on the roof.

QB RibRider

Components included: Stainless Steel Roof bracket with 4 - 14 x 1 ¼" Hex Washer Self-Drilling Screws. Mount is equipped with two factory-applied butyl pads on both bases and a rotating L-bracket for mounting at 90 or 180 degrees. PN #17766

Tools needed: 3/8” socket or nut setter (for 1/4 x 3/4” Screw) and 1/2” socket or wrench (for M8 Flange Nut).

Advantages: The QB RibRider is ideal for installers and contractors working on exposed fastener, trapezoidal, or ribbed metal roofs. It provides an adjustable base that fits various rib widths, heights, and angles, making it compatible with multiple roof profiles. It includes 75mm butyl pads for strong weatherproofing and a rotating L-bracket for mounting at 90 or 180 degrees. This mount is easy to place and secure, providing a solid attachment to the roof.

How does it install: The QB RibRider’s width is adjustable. To adjust mount to rib profile, loosen center nut to adjust width of the arms. For bottom rail mounting, rotate the L-Foot flat side up. By default, the L-Foot is flat side down for side rail mounting. Once center nut is loosened, remove protective paper from Butyl. Next, place the mounting arms Butyl side down on rib in marked location. Fasten mount to rib using included screws, then tighten center nut and check angle of L-Foot. Torque values should not exceed 20 PSI. Screws will drive in with little or no pressure required. Too much pressure could cause spinout. Do not predrill.

Certifications: UL Recognized Components, PE Tested

Distributors list: Wesco, CED Greentech, CES, Codale Electric Supply, Cooper Electric, Beacon Solar Products, Griprac, Independent Electric Supply, Onesource, Ontility, Tamarack Solar Products, The Solar Raq, Boral Roofing, Chiko Solar, Platt Electric Supply, Krannich Solar, Soligent and more…

IronRidge

IronRidge, an Esdec company, designs and manufactures structural hardware for residential and commercial solar systems. For nearly a quarter of a century, IronRidge has worked closely with solar professionals to build strong, streamlined, and cost-effective products. IronRidge is NSF Certified to ISO 9001, maintaining the highest of quality management standards.

*NEW* Aire Flush Mount System

Components included: The Aire Flush Mount System comes with -/+10 components, including two rail span options of 6’ and 8’.

TOOLS REQUIRED:

- Cordless Drill (non-impact)

- Impact Driver (for lag bolts)

- Torque Wrench (0-250 in-lbs)

- 1/2" Socket

- 7/16" Socket

- 7/32" Drill Bit

- 1/8" Drill Bit

- 5/8" Socket

- 1/4" Drill Bit

- T30 Torx Bit

- Channel Lock Pliers

- #3 Phillips Bit

- 3/16" Hex Bit

Certifications: Class A Fire Rating, UL 2703 Listed System, NEMA VE 1, certified for holding PV cables, 25-Year Warranty, Water Seal Rating, Florida Product Approval #FL29843

How does it install: The general installation method for attachments is to locate a rafter, drill a pilot hole and install the attachment.

Advantages: Aire is Racking Accelerated. IronRidge worked hand-in-glove with installers to provide the strongest, feature-rich, open-channel rail on the market. Two rail sizes come in black-anodized and mill finishes. Listed to UL 2703 and backed by a 25-year warranty.

*NEW* HUG: Halo UltraGrip

Application: Mount HUG to the roof rafters, the roof deck, or both with IronRidge's custom-engineered RD (rafter-or-deck) Structural Screw.

Material: HUG utilizes a multi-tiered stack of components to provide revolutionary waterproofing protection. The Halo cast-aluminum, raised-perimeter foundation surrounds the UltraGrip base—a foam-backed mastic seal combination that prevents water intrusion by adhering and sealing with the shingle surface.

How does it install? HUG UltraGrip utilizes a seal design that uses a unique, foam-and-mastic combination. The foam-backed adhesive provides an entirely new flashing system that conforms and adheres to every nook and cranny of composition shingles, filling gaps and shingle step-downs (up to 1/8” in height). Mount HUG to the roof rafters, the roof deck, or both with our custom-engineered RD (rafter-or-deck) Structural Screw. The RD Structural Screw anchors HUG to the roof with an EPDM sealing washer, completing the stack of waterproofing barriers.

Key feature: Many asphalt shingles have bonded courses. HUG is a mount that protects without the need to pry shingles and can really speed things up. HUG accelerates the installation process and provides the utmost in waterproofing protection.

XR Flush Mount System

Number of pieces: +/- 10

Tools needed: Cordless Drill (non-impact); Impact Driver (for lag bolts); Torque Wrench (0-250 in-lbs); 7/16” Socket; 1/2" Socket; 9/16" Socket; 7/32" Drill Bit; 1/8" Drill Bit; 1/4" Drill Bit; T30 Bit; Channel Lock Pliers; #3 Phillips Bit

Certifications: UL 2703 Listed, Class A Fire Rating, Water Seal Rating, Designed and Certified for Compliance with the International Building Code & ASCE/SEI-7, Florida Product Approval #FL29843

Installation:

1. Attach bases

2. Place rails

3. Secure lugs

4. Secure modules

Advantages: Every component in the IronRidge XR Flush Mount System has been tested to the limit and proven in extreme environments: rain, wind and snow. Our rigorous approach has led to unique structural features, such as curved rails, universal fastening objects, innovative tile attachments and reinforced flashings. All of our products are fully-certified, code-compliant, listed to UL 2703 and backed by a 25-year warranty.

XR Tilt Mount System

Number of pieces: +/- 8

Tools needed: Cordless Drill (non-impact); Impact Driver (for lag bolts); Torque Wrench (0-250 in-lbs); 5/16” Socket; 7/16” Socket; 9/16” Socket (deep); String Line

Certifications: UL 2703 Listed, Class A Fire Rating, Designed and Certified for Compliance with the International Building Code & ASCE/SEI-7

Installation:

1. Attach bases

2. Add tilt legs

3. Place rails

4. Secure lugs

5. Secure modules

Advantages: Build strong and efficient solar arrays on flat roofs. IronRidge Tilt Mount supports a wide range of solar panel tilting angles, while also resisting the extreme wind and snow forces experienced over a building’s lifetime.The Tilt Mount System is listed to UL 2703, and compatible with most roof anchor products. Every component in the system is made with aluminum and stainless steel to ensure complete corrosion resistance.

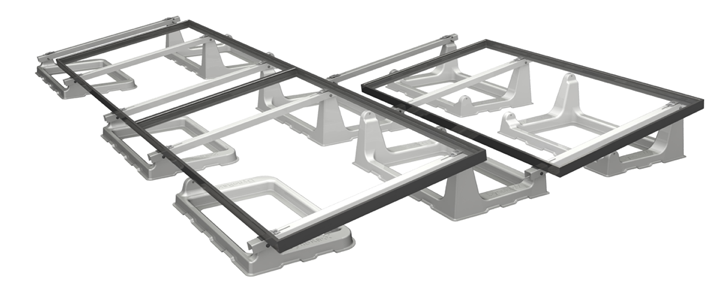

BX System

Number of pieces: +/- 5

Tools needed: Torque Wrench (0-250 in-lbs); 9/16” Socket; 7/16” Socket; 1/2" Socket; String Chalk Line

Certifications: UL 2703 Listed, Class A Fire Rating, Designed and Certified for Compliance with the International Building Code & ASCE/SEI-7, Wind Tunnel Testing by I.F.I.

Installation:

1. Mark layout

2. Place Chassis

3. Mount MLPE (optional)

4. Lay ballast

5. Anchor system (optional)

6. Install modules

7. Complete bonding

Advantages: IronRidge BX delivers superior power density and design flexibility to flat roof solar arrays. Made of a glass reinforced composite, the BX Chassis is engineered for extreme structural loading, yet is also shaped to be roof-friendly and easy to install.

Contour Solar Array Trim

Application: Contour Trim is installed on a completed array

Material: 6000 Series Aluminum, Black finish

How does it install? The Contour Trim connects along the front facing edge of the installation. The Contour Clamp secures to bottom flange of most modules, which the Trim piece slides into, and is secured into position.

Key feature: Contour Solar Array Trim is an aesthetic trim for solar array installations that provides a sleek trim (or skirt) across the south edge or around the perimeter to hide components that are visible beneath the solar panels.

Website | Email | Distributors

SunModo

SunModo, meaning “the way of the sun,” is a private U.S. company headquartered in Vancouver, Wash., that is focused on innovative racking and mounting solutions for professional installers in the fast-growing solar industry. SunModo’s solar racking solutions are at work in 15 countries, and from Hawaii to Connecticut, and their commitment to innovation can be seen across their product line, which includes 20-plus patents, from residential rooftops to large-scale ground-mounts.

MRB

Components included: MRB Mount, 4 Self-drilling Screws

Tools needed: Impact Driver, 13mm socket

Certifications: High-Velocity Hurricane Zone Approved – Passed TAS 100 (a) Wind Driven Rain Test

How does it install: The MRB Mount installs into 26-gauge sheet metal, 1/2 plywood or 7/16 OSB roof decking material. Remove the protective linear covering the EPDM gasket adhesive. Secure to 26-gauge minimum thickness sheet metal using four Self-drilling Screws. Adjust the L-Foot with its M8 Bolt onto the top of the clamp; use a 13mm (1/2”) hex socket and torque to 13Nm (10 ft-lbs).

Advantages: MRB is a versatile metal roof attachment. Specially designed to work for various metal roof profiles, the MRB adjusts to attach to almost any metal roof. Pre-applied adhesive makes attachment easy. Adjustable “wings” make MRB the single SKU solution for any shape metal roof.

- Most versatile metal roof attachment on the market.

- Fully pre-assembled with adhesive gasket.

- Simple, fast anchoring to sheet metal or wood decking.

NanoBit

Components included: NanoBit, 1 lag bolt

Tools needed: Impact Driver, 13mm socket

Certifications: High-Velocity Hurricane Zone Approved – Passed TAS 100 (a) Wind Driven Rain Test; Florida Product Approval (FPA)

How does it install: Apply a circular bead of sealant around the bottom of the NanoBit. Locate the center of the truss, rafter, or purlin in the desired roof location and drill a pilot hole. Clean sawdust, and fill hole with sealant. Use a 13mm (1/2”) hex socket to install the Lag Screw.

Advantages: SunModo is proud to introduce NanoBit, Solar’s Fastest Attachment for Metal Roof. Specially engineered for easy installation, NanoBit is the fastest installing metal roof mount in the industry.

- One of the fastest solar attachments.

- Versatile mount works for both shingle and metal roofs.

- Engineered for easy, fast installation on metal roofs.

SMR System

How does it install: One tool assembly and Pop-On technology allow fast and worry-free installation. Fast and easy Pop-On L-Foot Adaptor speeds installation and eliminates old-fashioned T-Bolts. Rail pops into Adaptor quickly and securely. Fully structural bonding splice with fast and easy single bolt installation. The Bonding Pop-On Universal Mid Clamps accommodate PV module frame heights ranging from 30mm to 50mm. Clamp pops on to rail easily and stays upright on rail for easy location adjustment. The Pop-On Universal End Clamps provide fast and easy install with a single SKU for any module thickness. The wire management clip is specially designed for a fast and secure solution for wire management. Pair SMR with one of our industry leading mounting options and save money and time on your residential solar installations. For a more interactive look at SunModo’s SMR system, check out this video.

Advantages: SunModo introduces the SMR Pitched Roof System, the best value pitched roof mounting system on the market. The SMR System represents a huge leap in racking technology. Optimized design makes the SMR Rails not only the lightest but also the strongest rails on the market. With fast and easy Pop-On Clamps and L-Foot adaptors, professional installers can mount, adjust, and secure PV panels with a single tool. Whether rafter or deck, portrait or landscape, the SMR System is the ideal solution for your solar installation. Save money on materials and installation time.

NanoMount

Tools needed: Impact Driver, 13mm socket

Certifications: High-Velocity Hurricane Zone Approved – Passed TAS 100 (a) Wind Driven Rain Test; Florida Product Approval (FPA)

How does it install: SunModo recommends putting a bead of sealant on the bottom of the mount as an extra precaution – but the high performance gasket means NanoMount is not reliant solely upon user-applied sealant for protection. Both rafter and deck attachments are available so NanoMount has the flexibility to cover a wide range of scenarios and preferences. For rafter application, locate the center of the rafter in the desired roof location and drill a 6mm pilot hole. Fill the pilot hole with sealant and use a 13mm hex socket to install the Lag Screw with Sealing Washer. For decking application, locate the desired roof location and install the 4X Self-Tapping Screws with Sealing Washers. Complete the solar panel installation using SunModo’s SMR rail system.

Advantages: Damaging roof shingles used to be one of a solar installers’ worst challenges. SunModo’s newest patented NanoMount eliminates the need to lift shingles and and dramatically reduces the installation time. The NanoMount has an Integrated Ultra Soft Weather Sealing gasket that covers the entire bottom of the mount and is recessed to ensure proper compression. The Ultra Soft material conforms to uneven roof surfaces. There are no pre-punched holes, so the giant gasket seals around the screws to to achieve superior leak protection on roof surfaces. Pre-assembled sealing washers come with either lag bolt or decking screws to prevent water penetration from above. NanoMount has the flexibility to cover a wide range of scenarios and preferences with its verstile base that can be used for either rafter or deck mounting.

SunTurf Roof Mount

Certifications: UL2703

How does it install: SunTurf easily achieves 7′ leading edge height with low cost and provides convenient access to roof surfaces for maintenance and repair. No cutting, welding, or drilling. Adjust height and install posts with set screws. Pipe fittings attach quickly with set screws. Two-piece pipe caps make installation easy. Structural Splice with set screws for bonding. Fast rail attachmetn with T-bolts.

Advantages: The SunTurf flat roof system is perfect to elevate above obstructions such as HVAC, Pipes and Vents. The streamlined design combines the simplicity of a pipe-based system with next-level engineering. No drilling is required to attach the aluminum rails to the horizontal pipe. The system can easily achieve cost effective leading edge height of 7′ or more. By spanning over roof obstructions, the system takes full advantage of the available roof surface thereby maximizing the PV system size and increasing your ROI. The system aso provides convenient access to roof surfaces for maintenance and repair.

TopTile Mount

Components: 6"X4.5" Aluminum Flashing with EPDM Boot, Deck Stanchion and 3 wood screws

Tools needed: 28mm hex socket

Certifications: High-Velocity Hurricane Zone Approved – Passed TAS 100 (a) Wind Driven Rain Test; Florida Product Approval (FPA)

Advantages:

- Cut your tile roof mount installation time in half.

- Adhesive moldable flashing for ease of application.

- Deck mount - No need to find rafters.

- No more lifting roof tiles, or broken tiles.

How does it install: Our patented TopTile eliminates the need to deconstruct the tile roof and significantly reduces time and minimizes tile breakage during installation. The mount works with both flat and curved tile profiles. The TopTile Mount can used to mount directly into roof decking without removing tiles. Locate the desired location of the TopTile stanchion. Using a 2” tile hole saw, drill a hole into the tile. 28mm hex socket is used to install the TopTile stanchion into the deck of the roof. Spray the insulating foam sealant onto the roof deck through the three holes of the stanchion after installing the three wood screws. Remove the protective linear covering the butyl tape. Install Flashing over Stanchion and onto the tile. Attach the L-Foot to the stanchion. Complete the solar panel installation using SunModo’s SMR rail system.

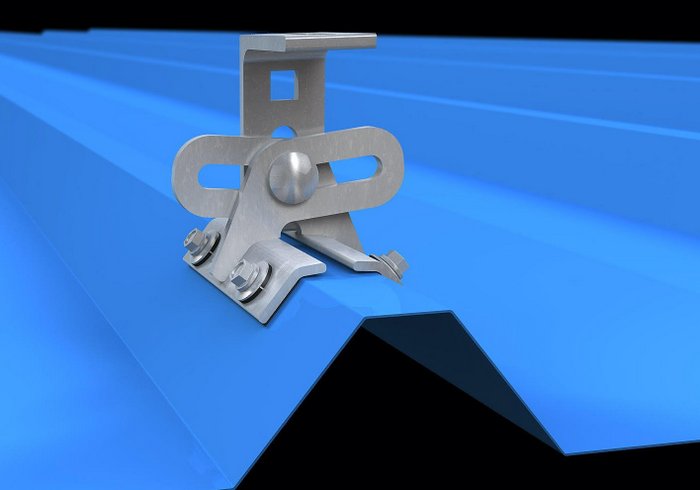

Standing Seam Clamp

Number of pieces: 1 piece (pre-assembled)

Tools needed: 13mm socket

Advantages:

- One product does everything you need on standing seam roofs.

- Attach SunModo's SMR Mid and End Clamps directly to the Standing Seam Clamp and you have a full racking system with no need for rail.

- Attach an L-Foot and use with any compatible rail-based system.

- One tool assembly with all SunModo roof mount products.

How does it install: Solar PV installations on standing seam roofs just got easier with SunModo’s Standing Seam Clamp. No rail needed. SMR Mid and End Clamps attach directly to the Standing Seam Clamp. Save the cost and time of using rail. Simply attach an L-Foot and the same Standing Seam Clamp can be used with a rail-based system.

Magerack

Magerack designs, manufactures and sells innovative solar mounting systems for roof-top solar installation. Magerack Solar Mounting System and MageMount Rail-less Mounting System are turn-key solar mounting solutions that are reliable, easy to install and cost-effective. In addition, Magerack also provides a variety of innovative roof attachments for solar installation on residential and commercial and industrial metal roofs.

Magerack Solar Mounting System

Components: Rail, Mid Clamp, End Clamp, Roof attachment with rail nut, and Rail splice

Tools needed: 1/2” hex socket

Certifications: UL 2703

Installation: It is a rail-based solar mounting system for solar installation on composition shingle, tile and stone-coated steel roofs.

Advantages: Reliable, easy to install and cost-effective

MageMount Rail-less Solar Mounting System

Components: Roof attachment with MageBolt, and Module Connector

Tools needed: 1/2” hex socket

Certifications: UL 2703

How does it install: It is rail-less solar mounting system for solar installation on composition shingle, tile and stone-coated steel roofs. It has only two components, Module Connector and Comp Foot. Comp Foot is attached to the roof and also secures solar module. Module Connector connects two adjacent solar modules for additional stability and bonding.

Advantages: Lower cost. Easy to ship, carry and install.

L-foot with Flashing

Components: L-foot with Flashing

Tools needed: 1/2” hex socket

Certifications: N/A

How does it install: L-foot with Flashing is roof attachment for composition shingle roof. Flashing is secured by attaching it to the vertical portion of the L bracket with a bolt.

Advantages: It has a unique and patented flashing design with no hole on the flashing surface so it is absolutely waterproof. It has a simple design and is intuitive to install.

C&I metal roof: Rail-less Standing Seam Metal Roof Mounting Kits

Components: Mid Clamp Mounting Kit and End Clamp Mounting Kit

Tools needed: 1/2” hex socket and 3/16” Allen key drive

Certifications: UL 2703

How does it install: Each kit has two components, MageBlock and mid or end clamp. MageBlock is attached to standing seam with two set screws. Mid or end clamp slides on top of MageBlock and secures solar module onto MageBlock.

Advantages: It has only two pre-assembled components, Mid-clamp Mounting Kit and End-clamp Mounting Kit. Each kit is 3”x3”x1” and multiple kits can be packed in one box. The cost is only one-third of rail-based mounting system and it is easy to install.

C&I metal roof: MageBracket RH, RL, CH and CL mounting brackets

Components: One mounting bracket

Tools needed: Hex socket

Certifications: N/A

How does it install: MageBracket RH, RL or CH has two angle-adjustable brackets that can be attached to the side of the rib for better waterproofing. MageBracket CL has two width-adjustable brackets that can be attached on the top of the rib of corrugated metal roof.

Advantages: Angle-adjustable and width-adjustable rib mounting brackets fit most common R-Panel trapezoidal and corrugated metal roofs. They have better waterproofing capabilities and are strong roof attachment with mounting screws attached to the sides of the rib or into the structural element. The optional L bracket is ready to be attached to rails.

C&I metal roof: MageBracket RH/RL Rail-less Mounting Kit

Components: Mid Clamp Mounting Kit and End Clamp Mounting Kit

Tools needed: Hex socket

How does it install: MageBracket RH or RL Mounting Kit is a simple and low-cost rail-less solar mounting system for R-panel trapezoidal metal roof. It has only two parts, mounting bracket and mid or end clamp. The angle-adjustable bracket with EPDM sealant fits most R-panel metal roof and is attached to the side of rib with self-tapping screws for better waterproofing. It utilizes the rib as rail and the bracket creates a mounting platform where the mid and end clamps secure solar panels on top of the bracket.

Advantages: It reduces mounting components dramatically, saves installation time and cost significantly and looks better aesthetically. Similar mounting kits are also available for standing seam metal roof and any metal roof with flat portion on the roof.

C&I metal roof: MageBracket F Rail-less Mounting Kit

Components: Mid Clamp Mounting Kit and End Clamp Mounting Kit

Tools needed: Hex socket

How does it install: MageBracket F Mounting Kit is a simple and low-cost rail-less solar mounting system for R-panel trapezoidal or standing seam metal roof or any metal roof with 3”x4” flat area for each mounting kit. It has only two parts, mounting bracket and mid or end clamp. Mounting bracket is attached to any 3”x4” or larger flat area on the roof with butyl sealant and secured to the deck or structure using up to four roofing fasteners. Universal mid and end clamps fit almost all solar panels.

Advantages: The bracket is attached to roof structure and can withstand stronger wind and heavier load. It reduces mounting components dramatically, saves installation time and cost significantly and looks better aesthetically.

MageFoot Rail-less Mounting Kit for Composite Shingle Roof

Components: Mid Clamp Mounting Kit and End Clamp Mounting Kit

Tools needed: Hex Socket

Certifications: N/A

Installation: MageFoot Rail-less Mounting Kit is a simple and low-cost rail-less solar mounting system for composite shingle roof. It has only two parts, mounting foot and mid or end clamp. Mounting foot is deck-mount bracket with butyl sealing gasket on the bottom. It can be attached to roof deck with four mounting screws or to structural element such as rafter with two lag screws. The mid clamp has integrated bonding capability to bond two adjacent solar modules when tightened. The universal end clamp fits all framed solar modules. It reduces mounting components, lower shipping cost, saves installation time and cost and looks better aesthetically.

Advantages: MageFoot Rail-less Mounting Kit is a simple and low-cost rail-less solar mounting system for composite shingle roof with only two parts, mounting bracket and mid or end clamp. It can be mounted on deck or to rafter. It reduces mounting components dramatically, saves installation time and cost significantly and looks better aesthetically.

OMG Roofing Products

For 40 years, OMG Roofing Products has been a leading supplier of fasteners and other products used exclusively in commercial roofing applications, and to secure commercial roofs to the deck. OMG works with all the major roof system manufacturers, and its field sales representatives are on commercial roofs every day.

PowerGrip Universal 7 (PGU-7)

Number of pieces: 2

Tools needed: Screw gun, wrench, torque wrench, water block bedding sealant, OMG roofing fasteners.

How does it install: OMG PGU-7 units are installed with four roofing fasteners for the specific deck-type. Fasteners should be installed with a standard screw gun rather than an impact driver, and cap bolts must be secured in a crisscross pattern to 60-70 inch pounds. A bead of water block sealant is installed around the perimeter of the bottom side of the top plate for added protection.

Advantages: For all commercial roof types (i.e., TPO, PVC, EPDM, modified bitumen, and BUR), but not compatible with residential shingles or tiles. Also, with most ballast and rail-based commercial solar rack systems. PGU-7s are secured directly to the deck and do not need to be secured to the structural members. This often eliminates the need for ballast and protects insulation from being compressed. PGU-7 units are watertight without flashing, which saves labor and eliminates the need for power on the roof during installation. Units can be installed in about four minutes. PGU-7 provides tensile strength of 2,051 lbf (9.12 kN), shear strength of 1,581 lbf (7.03 kN), and compressive strength of 2,214 lbf (9.84 kN).

C&I flat roof: PowerGrip Standard

Number of pieces: 1

Tools needed: Screw gun, fastener gauge card (supplied), thermoplastic roof hand welder, OMG roofing screws.

How does it install: The PowerGrip Standard is secured with the recommended roofing fastener through the roof and deck with a minimum deck penetration 3 ⁄4-in. [20 mm] into steel, and 1-in. [25 mm] into wood. The fastener head should sit firmly on the gauge card but should not be overdriven. Slide the PowerGrip assembly over the head of the fastener. The unit should sit snuggly onto the roof membrane. Heat Weld the flange of the PowerGrip to the roofing membrane per the manufacturer’s specifications and seal cut edges as required.

Advantages: Made with exactly the same thermoplastic (i.e., TPO or PVC) membrane that’s on the roof. Watertight. Helps protect single-ply roof covers from damage due to ballasted rack movement. Can help eliminate some ballast, to take excessive weight off the roof. Takes the wind-load off the roof cover and puts it onto the structural deck where it belongs. Offers tensile and shear strength of 305 lbf (1.35 kN). Only for use with ballasted systems on POV or TPO roofing membrane.

C&I flat roof: PowerGrip Plus

Number of pieces: 1

Tools needed: Screw gun, fastener gauge card (supplied), thermoplastic roof hand welder, sealant.

Certifications: n/a

How does it install: The PowerGrip Standard is secured with the recommended roofing fastener through the roof and deck with a minimum deck penetration 3 ⁄4-in. [20 mm] into steel, and 1-in. [25 mm] into wood. The fastener head should sit firmly on the gauge card but should not be overdriven. Slide the PowerGrip Plus assembly over the head of the fastener. Then lift the flange and install eight additional fasteners through the PowerGrip Plus plate, hitting the top flutes. The unit should sit snuggly onto the roof membrane. Heat Weld the flange to the roofing membrane per the manufacturer’s specifications and seal cut edges as required.

Advantages: Made with exactly the same thermoplastic (i.e., TPO or PVC) membrane that’s on the roof. Watertight. Helps protect single-ply roof covers from damage due to ballasted rack movement. Can help eliminate ballast, to take excessive weight off the roof. Takes the wind-load off the roof cover and puts it onto the structural deck where it belongs. Offers tensile strength of 2,000 lbf (8.90 kN) and shear strength of 1,075 lbf (4.78 kN). Only for use with ballasted systems on POV or TPO roofing membrane.

PowerGrip Universal 11 (PGU-11)

Number of pieces: 2

Tools needed: Screw gun, wrench, torque wrench, water block begging sealant, OMG roofing fasteners.

How does it install: OMG PGU-11 units are installed with six roofing fasteners for the specific roof deck-type. Fasteners should be installed with a standard screw gun rather than an impact driver, following the star pattern provided on the base plate. Apply a bead of water block bedding sealant around the perimeter of the bottom side of the cover plate. Align the cover over the base plate and bolt it in place with four bolts supplied, at a torque of 60-70 lbs.

Advantages: For all low-slope commercial roof types (i.e., TPO, PVC, EPDM, modified bitumen, and BUR), and compatible with most ballast and rail-based commercial solar rack systems. PGU-11s are secured directly to the deck thereby transferring wind uplift and dead weight loads directly to the structural members. This often eliminates the need for ballast and protects insulation from being compressed. PGU-11 units are watertight without flashing, which saves labor and eliminates the need for power on the roof during installation. Offers tensile strength of 3,343 lbf (14.8 kN), shear strength of 2,537 lbf (11.3 kN), and compressive strength of 2,749 lbf (12.2 kN).

EcoFasten

EcoFasten, an Esdec company, offers installer-friendly, cost-effective solar PV roof mounts and racking systems for the U.S. solar industry. The company has been in business since 2007 and its broad portfolio of patented watertight solutions are available in configurations for every roof type.

RockIt

Number of pieces: 4

Tools needed: One tool (1/2” deep well socket)

Certifications: UL 2703 and UL 3741.

Domestic content: US Components are also now available.

Installation: Installing the rail-less RockIt System on composition shingle roofing is not only one of the most economical solutions on the market, it’s also one of the fastest and easiest to install, thanks to the use of the watertight EcoFasten flashing that utilizes a single fastener. Once the flashing with RockIt Slides is installed and leveled on the eave edge, move on to installing the first row of RockIt Mounts, Array Skirts, and Couplings. All that’s left is to install the PV modules and continue the installation of upslope mounts and couplings. Level the remainder of the system as you go, or after installation of the PV array is complete.

Advantages: The RockIt System is the industry’s premier rail-less PV racking system available in configurations for composition shingle, tile, and metal roof types. Designed in conjunction with the needs of installers, RockIt quickly and easily installs with a single tool and features EcoFasten’s patented, watertight technology. With a convenient, easy-to-position alignment slide and a top-down leveling system, RockIt is logistically intelligent, with no need to ship or transport long rails. RockIt System provides a streamlined installation, fully integrated bonding, and North-South adjustability. Components are available in a black finish that complements both commercial and residential applications. RockIt conforms to UL 2703.

ClickFit

Number of pieces: 8 with Mid Clamps & End Clamps

Tools needed: One tool (1/2” deep well socket)

Certifications: UL 2703 and UL 3741.

Domestic content: US Components are also now available.

How does it install:

ClickFit on Tile: ClickFit is one of the fastest installing rail-based racking systems in the industry, thanks to the Click-in Rail assembly. ClickFit gives installers the versatility in attachment options they want and is the most cost-effective when installed on tile roofing.

To begin, install the ClickFit Tile Hook and replace the tile that was moved and/or removed, or install the Tile Hook Flashing. Install ClickFit Tile Hook Sub-Flashing next, providing an additional layer of watertight protection.

Place the rail in the Clickers and roll the rail into each Clicker – an audible “click” should be heard. Level if necessary, then install the ClickFit End Clamp on each rail (on whichever end you started with), place the PV module, align, and tighten.

Advantages: ClickFit conforms to UL 2703, features fully integrated bonding, and is one of the fastest installing rail-based systems in the industry. Thanks to its Click-In Rail assembly, the rails can be connected to any of EcoFasten’s composition shingle, tile, and metal roof mounts in seconds, without the need for fasteners or tools. The Mid Clamps and End Clamps are compatible with PV module thickness between 30-55mm.

The ClickFit system is fabricated from robust materials, such as aluminum and coated steel, to ensure corrosion-resistance and overall product longevity. ClickFit has been tested in extreme weather conditions including wind, fire, and snow.

ClickFit Smart Foot

Components included: ClickFit Smart Foot with Clicker

Tools needed: Caulking gun, roofing mastic applicator

Advantages: Created for use with our rail-based ClickFit System, the mount easily attaches to composition shingle roofs. Fabricated from cast aluminum, the ClickFit Smart Foot features our proprietary UltraGrip Technology™. A layer of foam cushioning helps to embed the waterproofing sealant deep into the granules of the shingle and flexibly conforms over the steps commonly found on architectural-style shingles. Simply peel the backing off the release liner from the underside of the UltraGrip pad and place the mount on the shingles.

How does it install: Simply peel the backing off the release liner from the underside of the UltraGrip pad and place the mount on the shingles.

Certifications: UL 2703, UL 2703A

Domestic content? Yes!

ECO-65 (C&I)

Number of pieces: 4

Tools needed: Two Tools (Phillips Head and ½” socket)

How does it install: Once the mounting location has been determined and the roofing and insulation have been cut to accommodate the base plate, install the flashing over the two threaded studs on the base plate, followed by installing the EPDM Sealing Washers over both threaded studs. Place the F-202 Compression Bracket over the threaded studs and place a single bonded washer over each stud with the rubber side facing the roof. Thread it down the stud to the compression bracket before adding the hex nut. Install and tighten down the hex nuts to each threaded stud. Next, attach the mounting bracket or post of your choice to the F-202 using the included all-thread, and finally, waterproof the EFL-BLK-1014 following the techniques specific to the roof membrane.

Advantages: The ECO-65 is a specialty direct-to-deck attachment for low-slope roofing. The roof attachment is engineered specifically for use on new or existing (retrofit) low-slope roofs constructed of rolled asphalt or membrane (TPO, EPDM, PVC). ECO-65 is used by countless manufacturers of ballasted solar racking systems to augment their products for weight reduction and seismic attachment. The ECO-65 base plate is designed to be attached specifically to wood blocking or wood decking, and the mount itself features two studs for attachment, which allows the use of larger compression brackets when needed. ECO-65 is a watertight solution compatible with any racking system.

RibFit

Number of pieces: 4

Tools needed: Two Tools (¼” hex socket, ½” socket)

Certifications: Conforms to UL 2703

How does it install: Determine array layout, mark center of corrugation, and draw a straight line indicating where Mounting Profile will be installed. Double-check the ridge width (minimum of 3/4”) and metal thickness (minimum of 26ga). The screw quantity tables will determine the number of screws needed. Attach the Mounting Profiles using the self-piercing screws and a cordless drill with a ¼” hex socket. The self-piercing screws are applied perpendicular to the roof surface, forming a watertight seal. Next, install End Clamps on the first two Mounting Profiles closest to the eave. Lower End Clamp to the Mounting Profile and “Click” the clamp over the side flanges. Place the first module, align and slide the End Clamp flush with the module frame. Tighten End Clamps and begin installing Mid Clamps. Complete by repeating the steps for each column of modules using the Mid Clamp Clicker as a spacer for consistent E-W gap between modules.

Advantages: The RibFit system is an easy to install, four-component, rail-less solar racking system designed for use on metal roofs. The RibFit system conforms to UL 2703 and consists of an aluminum slide that attaches directly to the top of the metal panel rib. Minimal components and integrated bonding pins reduce installation times when compared to rail-based systems. RibFit mounts modules in landscape orientation and is compatible with most metal R-panel and trapezoidal roof panels with a ridge width of ¾ inch or greater and 26-gauge or thicker. The RibFit system utilizes three levels of watertight protection for longevity and peace of mind.

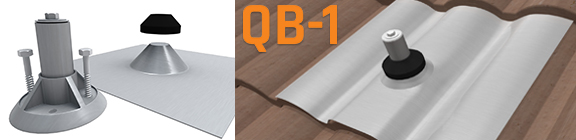

QB-1

Number of pieces: 4

Tools needed: One Tool (½” socket)

How does it install: QB-1 on Tile: QB-1’s strong, versatile post & base make it an ideal solution then mounting solar on tile roofing. To begin, locate each row of mounts and mark them off. Align the vertical fastener holes of the QB-1 Base over the center rafter mark then align the horizontal fastener holes over the snapped row line. Remove the QB-1 Base and place it over predrilled & backfilled pilot holes and secure fasteners. Secure the post to the QB-1 Base.

Once the underlayment is on, install the tile-level flashing, cutting where needed to allow the post to pass through it. Place the cut tile back into position and apply sealant where the post and the flashing meet. Attaching the desired bracket or L-Foot completes the installation.

Advantages: The super-strong and versatile QB-1 rail-based racking system includes a base that attaches to a variety of roof types including composition shingle, tile, shake, slate, and metal shingle. QB-1 is an ideal solution to use for new residential construction projects, as it allows for the roof to be shingled or tiled around the already installed mount. Aluminum cone flashings sized to fit the post are also available. Just combine the base with the post height of your choice (4.5” or 6.5” post heights are available), choose your flashing (12” x 12” or 18” x 18”), then choose your desired bracket.

Smart Conduit Mount

Application: For comp shingle roofs. Rail-based or rail-less applications. Structural or direct-attach.

Material: AL

How does it install? This mount installs quickly on composition shingle roofs and can rotate 360° for conduit runs in any orientation, giving the installer maximum flexibility. The Smart Conduit Mount features our proprietary UltraGrip Technology. A layer of cushioning foam helps to embed the waterproofing sealant deep into the granules of the shingle. Compatible with all conduit clamps (not included).

Key feature: UltraGrip Technology means no need to pry up shingle courses to install metal flashing, and no need to drill pilot holes. Smart Conduit Mount conforms to UL 2239 and UL 2703A.

Frame MLPE Mount

Material: Stainless Steel

Install: The Frame MLPE Mount attaches, mounts and fully bonds module level power electronics (MLPE) to the module frame using a single-bolt clip.

Key feature: This accessory can be used with any racking system to attach the MLPE to the module frame.

Contact: info@ecofastensolar.com

Website | Email | Distributors

Point Load Power

Point Load Power is a cleantech company leading the advancement of rooftop solar tracking for commercial and industrial (C&I) buildings while making it highly profitable for every partner and stakeholder involved.

C&I flat roof: PV Booster

Number of pieces: 12

Tools needed: Socket Wrench, Wire Crimper

Certifications: CSA for UL 3703

How does it install: PV Booster is mechanically attached to flat C&I rooftops. The three major subsystems install fast by torquing our tripod (support system) down to the mechanical attachment (included), bolting on the drive mechanism (actuator), and installing the h-frame (panel support). Panels are then mounted on the h-frame. The system is wired up in strings of 30 or less to our tracker distribution boxes (control hardware) mounted on the rooftops. The 30 degree tilted vertical axis tracker significantly improves energy production and requires about 1’ between panels to allow for a full range of tracking motion to achieve that goal. A small, wall-mounted control computer is installed in the mechanical/electrical room near the inverters to ensure functionality if the site loses internet connectivity.

Advantages: PV Booster brings tracking to flat C&I rooftops to dramatically increase system efficiency with a smaller footprint which significantly reduces the LCOE of your projects. PV Booster allows building owners to use less equipment to produce more energy from every panel. Our systems produce 30-40% more energy out of every monofacial panel. PV Booster is the best mounting solution for bifacial modules as well, producing as much as 70% more energy out of bifacial panel. Produce more with less using PV Booster, rooftop tracker.

Sollega

FR510-6 (UL 3741 Certified)

Components included: FR510-6 Ballasted Racking system with wire management clips and bonding clips (FR-SBJ).

Tools needed: ½” socket wrench

Certifications: UL2703, UL3741 Certified with SMA, CPS, Solectria, Solis (Ginlong) and GoodWe Commercial Inverters

Installation: Sollega, leading hybrid ballasted flat roof/ground mount racking provider has joined forces to certify the Sollega FastRack 510-6 with SMA Sunny Tripower CORE1 inverters, CPS, Solectria, Solis, Ginlong and GoodWe inverters as the first system to market that complies with Underwriters Laboratory (UL) 3741 Photovoltaic Hazard Control Systems (PVHCS) and National Electric Code (NEC) 690.12 rapid shutdown of PV Systems on buildings without module-level power electronics (MLPE) or switches. Inverter must be installed within 1’ of the PV array boundary and all stringing for that inverter must be within the PV array boundary. Our wire clips provide the required “airgap” and meet UL3741.

Advantages: Eliminate the upfront cost to procure and install MLPE’s and reduce the DC connections to 1/3 the count when installing MLPE’s. Long term O&M savings. Safer installation with reduced component failure.

S-5!

Since 1992, S-5! has been an authority on metal roof attachment solutions. S-5!’s zero-penetration clamps attach ancillaries to standing seam metal roofs (SSMR), while maintaining roof warranties. All S-5! products are warranted for the life of the roof (and solar). Manufactured in their ISO 9001-15 certified U.S. factory, S-5!’s products have been used on more than 2.5 million roofs worldwide, including 3.5 GW of PV.

CanDuit clamp

Application: Rail-less, Residential or C&I

Material: Made from electro-zinc-coated steel, the CanDuit clamp features a two-piece design that securely encircles the pipe or conduit. It is equipped with an EPDM liner pad to prevent abrasion, ensuring a secure and protective fit. Additionally, it includes a threaded M8 stud, allowing for easy attachment to S-5! products.

Key feature: The CanDuit clamp is a versatile solution that can be used in combination with any S-5! clamp or bracket. It securely attaches and supports chases and raceways, cable trays, gas piping, condensate lines and other round-shaped objects to metal roofs. It also pairs with the S-5! GripperFix utility mounting system. Available in 14 sizes, the CanDuit clamp accommodates outer pipe diameters ranging from .79" (20 mm) to 4.6" (117 mm). Its adjustable design allows for minor size modifications, ensuring a secure fit for most conduit and piping applications.

How does it install?

- Choose the correct size CanDuit clamp for your conduit application.

- Determine the location to place the conduit clamp.

- Attach the appropriate S-5! Clamp, bracket or GripperFix to the roof.

- Thread the conduit clamp into the S-5! Attachment or GripperFix rail.

- Loosen and remove the two Phillips screws from the CanDuit clamp and remove the upper half.

- Insert the conduit into the clamp, then replace the upper half and tighten the two Phillips screws.

PVKIT HUR

Components included: PVKIT HUR Mid; PVKIT HUR Edge

Tools needed: screw gun, T-30 Torx Bit Tip (provided); calibrated dial torque wrench

Certifications: Certified to FM Approvals toughest PV Standard—FM4478

How does it install? The PVKIT HUR installs like S-5!’s original PVKIT with pre-assembled components. The first step is to affix the HUR assembly to the job-specific S-5! clamps at a staging area. Once on the roof, the first row of PVKIT HURs is installed to the roof seams; only the two clamps at either end of the row need to be measured for location - then stringline the infills. Next, it is time to install the first-row of solar modules. As each module is installed, the PVKIT HURs are set against the open side of the module frame and attached “on the fly” to the seams or ribs of the roof using the module frame as the jig/spacer. No more measuring.

Advantages: The PVKIT HUR is the first rail-less PV mounting system designed for high wind uplift performance of installed solar panels, such as coastal communities and other high-wind and hurricane zone areas. It’s the first metal roof PV mounting system to achieve FM Approvals toughest PV Standard—FM4478.

- Provides a low-profile aesthetic solution

- Reduces materials required due to rail-less system

- Reduces carbon footprint

- Cuts installation time dramatically compared to traditional systems

- Reduces the cost and complexity of transporting materials

- Reduces added dead load of mounting components

- Improves load distribution by 25% over rail-based installations

- Warranted for the life of the roof/PV system

MLPE Mount

Tools needed: screw gun (13mm torx driver provided); torque wrench

Certifications: UL2703-certified component

How does it install? It is best to install module-level power electronics to the module frames during module preparation on the ground or at a designated prep area on the roof. The actual installation is simple and straightforward. Attach the S-5! MLPE Mount to the optimizer; then place the optimizer with one hand onto the frame while tightening with the other hand utilizing the proper tool. A unique tab feature makes installation quick and easy, preventing rotation of the MLPE as the mount is tightened.

Advantages: The MLPE Mount provides a universal, cost-effective method for attaching MLPEs directly to solar PV module frames. Designed for use with any flanged module, the MLPE Mount secures optimizers and microinverters along the underside of the module frame in less than 10 seconds. This provides the versatility needed to better handle module-to-module wire management and electrically bonds the equipment together to easily comply with grounding requirements. The MLPE Mount is ideal for use with all S-5! solar attachments for rail-less and rail-based installations, especially paired with the PVKIT rail-less solar mounting solution for direct attachment to metal roofs.

S-5-N clamp

Number of pieces: 2

Tools needed: electric screw gun (bit tip provided)

Certifications: material- ASTM B 221-04A, B 308/308M, B 597, B 807, E 527-83, A 276/276M; manufacturing- ISO 9001-15; performance lab testing- ISO 17025; product evaluation- ICC-ES (Evaluation Report ESR-3869)

How does it install: The S-5-N clamp can be used for rail mounting or rail-less Direct-Attach™. Installation is quick and easy with angled setscrews. Place the insert against the base of the seam at the desired clamp location. Place the clamp over the seam and insert. Tighten the setscrews against the insert to the specified tension with the provided Torx-tip. Then, for railed systems, affix your rail (or L-Foot) using stainless M8 bolt (available separately). Or, for rail-less, simply thread the pre-assembled PVKIT into the bolt hole in the top of the clamp. You are ready to lay modules!

Advantages: The S-5-N clamp is custom designed for popular 1" nail strip standing seam profiles that are popular for residential and light commercial roofs. Available in two models: Standard (2-screw) for heavy, load-critical applications, and at lower cost, the S-5-N-Mini is suitable for most PV applications. Versatile for use with rail-mounted systems or the S-5-PVKIT.

Benefits include: No special tools, superior corrosion resistance and holding strength and innovative insert facilitates installation. It preserves roof warranties and ensures straight clamp position on seam. Published tested holding strength for engineered application. Warranted for the life of the roof and PV.

ProteaBracket

Number of pieces: 1 (pre-assembled)

Tools needed: screw gun, string line, 5/16” and 1/2” drive sockets

Certifications: material- ASTM B 221-04A, B 308/308M, B 597, B 807, E 527-83, A 276/276M; manufacturing- ISO 9001-15; performance lab testing- ISO 17025

How does it install: ProteaBracket is a universal bracket for attachment of rail or the S-5-PVKIT to trapezoidal-ribbed (exposed-fastened metal profiles), with top width dimensions of up to 3” (76 mm). Secure directly onto the sides of the crown of the roof panel through the pre-punched holes. Stainless-capped, self-piercing S-5! fasteners and Protea L-Foot are included. The ProteaBracket eliminates the hunt for structure locations, enabling module, PVKIT or rail attachment anywhere on the roof.

When using a side-mounted rail, orient the Protea L-Foot vertically so the hinge bolt will lock into the square hole on the slotted L-Foot. Tighten the hinge bolt. The rail will now be attached to the remaining slot to fine-tune the rail height. When utilizing ProteaBracket to mount the PVKIT or top-mounted rail, orient the L-Foot horizontally. Tighten the hinge bolt.

Advantages: One part does it all. Fully assembled, the ProteaBracket attaches PV with or without rails to exposed-fastened trapezoidal sheet profiles, including pre-assembled foam core panels/insulated metal panels. Adjustable base accommodates varying rib widths, heights and angles. Attach to the sheeting-only with no messy sealants. Comes with a factory-applied, EPDM pad to ensure quick installation and a weather-proof fit. Rigorously tested for load-to-failure results in sheeting-only; pairs with the PVKIT for a direct-attach solution – or ideal for both side-bolted and bottom-bolted rail mounting. As with all S-5! products, ProteaBracket is warranted for the life of the roof (and PV); Resi or C/I.

S-5! Mini clamps

Number of pieces: 1 or 2 according to roof profile specifics

Tools needed: electric screw gun (bit tip provided)

Certifications: material- ASTM B 221-04A, B 308/308M, B 597, B 807, E 527-83, A 276/276M; manufacturing- ISO 9001-15; performance lab testing- ISO 17025; product evaluation- ICC-ES (Evaluation Report ESR-3869)

How does it install: Use the threaded holes in the clamp (with provided stainless hardware) to mount PV modules, snow guards, service walkways, lightning protection, conduit, wire chases, module-level-power electronics, fall protection and more. All use tools common to the trade with installation so simple; it can be done by a DIY installer. Just place the S-5! clamp over the seam at the desired location and tighten setscrew(s) to specified tension. M8 threaded hole provided in all clamps for attachment of L-foot (railed systems) or S-5-PVKIT (Direct-Attach™) systems without rail.

Advantages: S-5! clamps are designed for brand-specific standing seam roof types, gauges and materials to maximize cost/holding strength ratios. A one-size-fits-all clamp compromises either cost or performance. All “mini” clamp versions are more than adequate for PV mounting. It is compatible with any rail system, no roof penetration needed. Compatible with S-5-PVKIT for (rail-less) Direct-Attach systems. Independently tested on more than 500 metal roof profiles for engineered applications. Warranted for the life of the roof (and PV). Available in brass, stainless

SolarFoot

Number of pieces: 1 (fasteners sold separately)

Tools needed: electric screw gun, 3/8” Hex Socket, 13 mm (or 1/2”) Hex Socket

Certifications: material- ASTM B 221-04A, B 308/308M, B 597, B 807, E 527-83, A 276/276M; manufacturing- ISO 9001-15; performance lab testing- ISO 17025

How does it install: To install SolarFoot for the rail and L-Foot of your choice: 1. Determine the location of the supporting structure of the roof; Wipe away excess oil and debris from the desired mounting location; 2. Peel the release paper from the base, align and apply to roof surface at structure location; 3. Install screws through the pre-punched holes in the SolarFoot into the structure below; and 4. Install the rail-producer’s L-Foot over the stud and secure in place with the provided M8-1.25 Hex Flange Nut tightened to 160 inch pounds (13 ft lbs).

Advantages: Suitable for all exposed-fastened metal roofs and compatible with all rail manufacturer’s L-Foot components. Attaches into the structure or deck for optimal holding strength. Fastens into a variety of substrates, including wood deck, wood or steel purlins. Proper sealant selection never left to chance; no messy or risky field-applied sealant. Low center of gravity reduces moment arm commonly associated with L-Foot/rail solar racking. Stainless integrated stud and locking Flange Nut secure the L-Foot into position. Load-tested for engineered applications. Warranted for the life of the roof (and PV)

SnapNrack

Since 2007, SnapNrack’s solar mounting products have been designed to reduce installation costs, improve installation quality and safety. SnapNrack roof and ground mount systems feature a single tool installation, pre-assembled snap-in hardware, integrated wire management, integrated grounding/bonding and Class A Fire Rating in accordance with UL2703/UL1703 standards.

SnapNrack Ultra Rail

Number of pieces: 5 (Rail, Mount, Splice, Mid Clamps and End Clamps)

Tools needed: ½” socket with an impact gun for all connections and attachments

Certifications: UL 2703 for Grounding/Bonding, Class A Fire Rating Type 1 & Type 2 Modules, UL Certified Modules, Stamped Structural Engineering Reports

How does it install: Installation of SnapNrack Ultra Rail is intuitive and easy to learn. After the array is marked in accordance with the design plans, Umbrella L Feet lag into rafters with patented flashing technology that protects against roof leaks. Rails snap into mounts with spring loaded features to allow the rail to easily slide and be adjusted to the desired location and height. Finally, panels are placed on the rails secured using SnapNrack’s proprietary mid and end clamps as wires are nestled securely into the rail channel.

Advantages: The Ultra Rail profile creates a channel for wires, unobstructed by splices or mounts. It doesn’t rely on zip ties which can fail over time creating opportunities for wire damage or worse. Spring loaded brackets allow the rail to snap into place and be released, without tools, and easily slide prior to leveling and tightening. SnapNrack doesn’t rely on T-Bolts that can bind or be improperly installed, resulting in a system failure. Roof penetrations are protected with a patented cone flashing feature that extends above the base of the roof attachment and sealed under a proprietary Umbrella Lag.

UltraFoot for Ultra Rail

Components: UltraFoot with a 0.25” butyl pad. Optional Fasteners: SnapNrack DeckAnchor, Standard 5/16” lag screw, #14 wood screw, #14 self-tapping steel fasteners, 3/8” wedge anchors

Tools needed: ½” socket with an impact gun for all SnapNrack connections and attachments

Advantages: With UltraFoot™ SnapNrack has expanded roof sealant methods with pre-installed butyl pads for easy peel & stick installation, eliminating composition shingles disruption. SnapNrack butyl pads are industry-leading at 0.25” thick, and have passed TAS 100 Wind Driven Rain Testing, ensuring the attachment is fully sealed, and watertight. Roof attachments with butyl remove the need for additional sealant during install, streamlining the process, and saving time for installers while ensuring a secure, weatherproof attachment. Maintaining familiar SnapNrack traditions of single tool installs, DeckAnchor™ has a ½” hex head. Wide threads securely grip roof sheathing and significantly reduces the potential for over-tightening.

How does it install: Engineered with butyl, now installers do not have to add sealant to the bottom of the mount, simplifying the installation process and further protecting the roof. The UltraFoot has pre-installed butyl for easy peel stick installation eliminating disruption to composition shingles, and this butyl pad is an industry-leading 0.25” thick allowing installation over shingles without cutting extra pieces of butyl. The new UltraFoot is available in three configurations to accommodate rafter and deck mounting based on DeckAnchor or wood screw install preferences. All ships pre-assembled with the new Ultra Rail Flip Clamp Mount that centers the load over the fastener and creates an easier snap-in experience with UR-45 Rail, especially UR-45 Mill Rail

Certifications: The SnapNrack Ultra Rail Mounting System is certified to UL 2703 standards for Grounding/Bonding, Class A Fire Rating Type 1 & Type 2 Modules, UL Certified Modules, Stamped Structural Engineering. The UltraFoot™ with DeckAnchor™ has passed TAS 100A wind driven rain and ASTM D7147 structural tests and will soon have Florida product approval for use in High Velocity Hurricane Zones (HVHZ). Additionally, the DeckAnchor™ was tested by means of ASTM D1761 standard test methods to generate screw capacities.

Domestic content? Yes. Refer to the SnapNrack Product Catalog and reference SKUs with “-USA” to note as a domestic content product.

TopSpeed Mounting System

For: Residential

Components included: TopSpeed™ Mount & TopSpeed™ Clamp, ½” SnapNrack Wood Screw, uses existing SnapNrack Universal Skirt & Spacers, and railless Wire Management

Tools needed: ½” socket with an impact gun for all connections and attachments

Certifications: UL 2703 for Grounding/Bonding, Class A Fire Rating Type 1 & Type 2 Modules, UL Certified Modules, Stamped Structural Engineering Reports

How does it install: The simplified process consists of 3 basic steps: On the ground TopSpeed Mounts are attached directly to the panels in the approved mounting locations. Then, while still on the ground, wire management begins with SnapNrack Smart Clips and MLPE Frame Kits to prep module leads & MLPEs, resulting in a faster mounting install experience. While these steps are being performed on the ground, array layout & the first row of TopSpeed Mounts with the Universal Skirt are installed. Installers are then ready to install at TopSpeed. All mounts are secured to the roof with SnapNrack’s ½” wood screws after modules are positioned in desired location.

Advantages: The majority of the TopSpeed install process is performed on the ground. Except for the first row of mounts for the Universal Skirt, all TopSpeed Mounts are attached directly onto the modules before the module is brought up on the roof. TopSpeed is fundamentally changing the installation process to cut down on roof layout, staging material, and assembling of racking. This installation process also cuts down the amount of time installers are exposed to safety risks by spending long periods of time on the roof. TopSpeed brings the process to the ground for a safer experience.

AnchorFoot and DeckAnchor

Components included: AnchorFoot with a 0.2” butyl pad

Optional Fasteners: SnapNrack DeckAnchor, Standard 5/16” lag screw, #14 wood screw, #14 self-tapping steel fasteners, 3/8” wedge anchors

Tools needed: ½” socket with an impact gun for all SnapNrack connections and attachments

Certifications: The SnapNrack Ultra Rail Mounting System is certified to UL 2703 standards for Grounding/Bonding, Class A Fire Rating Type 1 & Type 2 Modules, UL Certified Modules, Stamped Structural Engineering. The AnchorFoot™ with DeckAnchor™ has passed TAS 100A wind driven rain testing, and the DeckAnchor™ was tested by means of ASTM D1761 standard test methods to generated screw capacities.

How does it install: AnchorFoot & DeckAnchor together are designed to reduce the number of roof fasteners when fastening directly to roof sheathing and to provide flexibility to mount anywhere on the roof, including rafters or purlins. Engineered with butyl, now installers do not have to add sealant to the bottom of the mount, simplifying the installation process and further protecting the roof.

The AnchorFoot has pre-installed butyl for peel & stick installation, eliminating disruption to composition shingles. Flexible installation options include: fastening to roof sheathing with (2) DeckAnchors or (4) #14 wood screws, rafter mounting options with (1) 5/16” lag or (2) #14 wood screws. Multiple other fasteners can be used including #14 self-tapping steel fasteners. Ships pre-assembled with Ultra Rail Mounting Clamp for easy rail attachment.

Advantages: SnapNrack butyl pads are 0.2" thick, and have passed TAS 100 Wind Driven Rian Testing. Roof attachments with butyl remove the need for additional sealant during install, streamlining the process, and saving time for installers while ensuring a secure, weatherproof attachment. Maintaining familiar SnapNrack traditions of single tool installs, DeckAnchor has a ½” hex head. Wide threads securely grip roof sheathing and significantly reduces the potential for over-tightening.

SnapNrack RL Universal

Number of pieces: 4 (Mount, Link, Skirt & Spacers)

Tools needed: ½” socket with an impact gun for all connections and attachments

Certifications: UL 2703 for Grounding/Bonding, Class A Fire Rating Type 1 & Type 2 Modules, UL Certified Modules, Stamped Structural Engineering Reports

How does it install: RL-U is designed such that each install step is independent, where a single installer can install the entire system. The roof attachments are a Flash Track which provides North-South adjustability, secured with a single Umbrella Lag through SnapNrack’s patent pending Umbrella Flashing. RL-U only requires a single RL-U Mount SKU, which is used at all locations on the array. The integrated RL-U Skirt attaches to the first row of mounts, creating a strong structure for leveling and aligning the array. The RL-U Links clamp onto the top of modules securing them in place while providing row-to-row bonding, and provide an attachment point for 2-4 modules. A single installer can drop modules into place, and secure them across the top without having to reach down the roof across a module.

Advantages: RL Universal is designed to provide the fastest, most intuitive install experience on the roof. The direct mount system features four basic components, with nothing larger than the size of a module, resulting in easy material management. Features include an integrated Skirt for a secure installation with sleek aesthetics, Universal Mounts used at all locations on the array & Links that can accommodate 2-4 modules. Mount & Link interference is eliminated with the unrivaled Mount offset & Link adjustability. RL-U is the only railless system to offer labor saving installation processes backed by the industry leader in residential solar.

SnapNrack SpeedSeal Technology

Number of pieces:

- 2 (SpeedSeal Foot or SpeedSeal Track & Lag Screw) OR

- 5 (SpeedSeal DeckFoot or SpeedSeal DeckTrack & 4 Wood Screws)

Tools needed: ½” socket with an impact gun for all connections & attachments for Foot & Track with Lag

Certifications: UL 2582 Wind Driven Rain Test and ASTM E2140 Water Column Testing standards, Miami-Dade NOA No: 20-1104.01, UL 2703 for Grounding/Bonding, Class A Fire Rating Type 1 & Type 2 Modules, UL Certified Modules, Stamped Structural Engineering Reports.