Ground-Mount Solar BOS Buyer’s Guide 2025

Solar PV can be mounted and energized atop of nearly any ground conditions you’ll encounter across the United States – from vast Western deserts to rocky, frozen Northeastern soils and everything in between. But you already know that. Yesterday’s “challenging sites” are just the status quo in ground-based solar projects in 2024.

In the 2025 Ground-Mount Solar BOS Buyer’s Guide, we showcase the latest and greatest in structural (trackers, carports, fixed-tilt mounts) and electrical balance of systems (cable and wire management) for any ground-based solar project. We asked each manufacturer what’s new with this year, and to update their system specs.

What’s new in trackers in 2025?

Terrasmart launched multiple solutions to support First Solar Series 7 TR1 modules—both fixed tilt and tracker. This gives developers significant flexibility when determining the most cost-effective way to qualify for the 10% domestic content tax-credit. Terrasmart also launched hail-stow as part of their severe weather/terrain controls package that already included wind, snow, and topo-informed backtracking.

OMCO turns 70 this year and, under OMCO Solar, has shipped 11 GW worth of solar mounting structures in that time. OMCO Solar already offers an all-US fixed tilt rack, and by mid-year will be offering an all-US tracker. Later in Q3, OMCO Solar will be launching the OMCO Star Tracker Control System featuring reliable long-range LoRa wireless technology, industry-leading weather features, advanced monitoring, and major maintenance cost-savings all made in the US. Overall, the company continues to provide factory-direct solar tracker and fixed tilt solutions, domestic supply chain, and the shortest lead times in the industry.

ARRAY will start shipping their new SkyLink Tracker system in 2025. This system is an eight linked row architecture with a PV string-powered brushless DC motor, Zigbee wireless communications, and the full suite of ARRAY SmarTrack features with passive wind mitigation.

At RE+ last year, Nevados launched the TRACE All Terrain Tracker, a follow-up to their original All Terrain Tracker that features some significant updates – specifically 75-degree hail stow, energy optimization features, enhanced tracker controls, and the same best-in-class terrain capabilities. We covered some of the updates in our Intersolar 2025 recap.

PV Hardware USA forecasts a continued surge in utility-scale solar capacity through expanded onshoring of manufacturing, innovation against weather-related losses, and the introduction of groundbreaking technologies. PVH’s goal is achieving 100% domestic content for solar trackers by 2025.

Polar Racking’s latest advancements for the SOL-X single axis tracker include 3D Backtracking, Advanced Overcast, and Severe Weather Protection. They’ve also launched a lineup of fixed and tracker systems for agrivoltaics projects. “In 2025, we’re continuing to expand our manufacturing worldwide, and from an R&D standpoint exploring more terrain following products.”

If you are looking for dual-axis tracking, Stracker Solar started manufacturing and installing its newest model, Stracker S1B2, that carries 28 large-format PV modules (typically 550-590W) for even more power production per square foot that its predecessor.

What’s new in cable management in 2025?

RP Construction Services is now Ampacity Renewables to better reflect its full breadth of products, which includes electrical balance-of-system products. “For years, we have made our customers successful with single-axis tracking products through passionate design, fulfillment, and field support. We are now bringing the same approach to electrical goods, streamlining procurement of wire and cable, wire management solutions, cable accessories, grounding and bonding, and strut and conduit.”

Gripple is supplementing its solar offering with a brand-new Solar Cable Bridge, designed to safely and securely manage string cable over tracker bearings or motors. Now approved for use with Array Technologies tracker systems, the Gripple Solar Cable Bridge can be used in combination with Gripple’s Power-Tie.

CAB Solar has unveiled ModulAir, a new NEC Free Air Code Compliant above-ground cable management system. ModulAir utilizes a tiered system to maximize cable separation and optimize air flow around cables. CAB Solar has also expanded its manufacturing and shipping capacities by building a 30,000+ square foot warehouse/shipping facility next to its Ebensburg, Pa. factory.

Snake Tray’s Solar Snake Max above ground cable management product for single messenger provides a multi-tiered cable manager to accommodate cables up to 1250 Kcmil. The patented open adjustable click system can manage a variety of cables on the same tier, and it maintains NEC 310.15 code compliant cable separation. No derating of cables for lower material costs. In stock and ready to ship.

Affordable Wire Management (AWM) continues to innovate Cable Management Systems (CMS). In 2025, AWM’s CMS will be offered for utility-scale solar and BESS projects. AWM offers three versions of their CMS, each with hangers that are custom-designed and ampacity-optimized for all real-world scenarios.

What’s new in carports and fixed-tilt in 2025?

For SunModo, 2025 will include the introduction of SunTurf TT Ground Mount System. With just two tools required for assembly—specifically, a 13mm and a 15mm socket driver—a 15kW SunTurf system can be fully installed within a single day on the job site.

In addition to their flagship pop-up solar powered microgrid canopy, PairTree, Paired Power announced a new PairFleet system that can scale to much larger system sizes of solar, battery storage, and EV chargers.

World4Solar has a versatile 30 kWdc charging solution designed for both off-grid and grid-tied applications, developed in collaboration with Schneider Electric.

Infinity Rack now has Fully Cantilevered Solar Structures with custom wide spans and over 30’ low clearances. You can frame-in beneath their aluminum structures to create secure areas for any use. Additionally, their free 3D Configurator allows you to instantly render any size solar canopy that your client needs.

In the Guide below, you’ll find submissions broken into the following categories:

- Trackers and turnkey providers

- eBOS only

- Fixed tilt and canopy

NOTE: Click on on any product listed under each manufacturer in order to expand the section and see what it looks like, check out the specs, understand how to install it and learn a few other key features of the design.

If your company is missing, email our editors for inclusion.

Trackers and turnkey providers

Company specialty: End-to-end solution provider for Solar PV projects including development software, racking, foundations, canopy/carport systems, eBOS products, and installation.

MWs installed in North America: 25 MW’s installed to-date

U.S. manufacturing: We have three manufacturing locations in the U.S. 1) Cincinnati, Ohio 2) Grand Rapids, Michigan 3) Selkirk, NY with over 2 GW annual capacity.

Turnkey services

- Design & engineering: Geotechnical, structural, mechanical, electrical and civil engineers provide project-specific, value-engineered solutions.

- Turnkey construction: Specializing in professional surveying, drilling, screw, racking and panel installation.

- Surveying: Site topology and 3D mapping.

TerraBOS Flex

Material: Combiner box, wire harness, source circuit

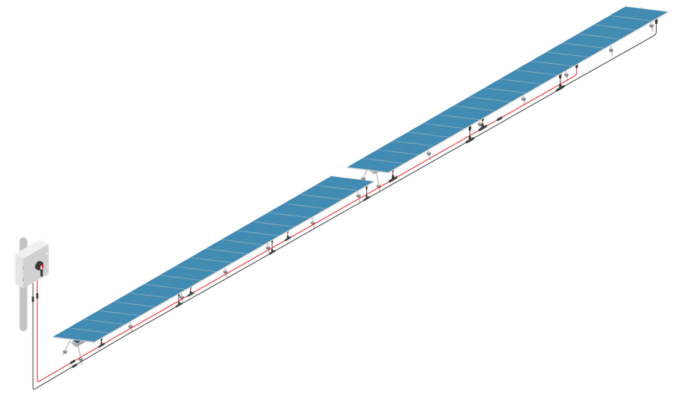

Basics: Complete eBOS solution for sites leveraging the unmatched flexibility of the Home Run architecture. TerraBOS Flex is a full eBOS solution from wire to combiner boxes. All components are pre-fabricated and customized to project specs, making in-field installation faster, easier, and more reliable. Factory assembled for quality control; TerraBOS Flex is customizable at scale.

Key features: Fully integrated and customizable source circuit cabling, harnesses, and DC Combiner Boxes drive high reliability and improved installation vs field fabricated or piecemealed solutions.

- Reduce installation costs with a pre-fabricated solution that allows for fast plug-and-play connections in the field

- Flexible design to work with wire hangers, cable trays, and trenching solutions

- Factory assembled in a quality-controlled environment, ensuring long term reliability

- Diagnose issues at the box level for faster troubleshooting and less downtime

- The use of whips, jumpers, and pre-installed mounting hardware reduces time on site

- Thorough quality process and testing ensures long term reliability

- 8.5+ GW of eBOS deployed across the U.S.

- Our customer focused, value engineered designs save you time and money

Installation explained: The TerrasBOS Flex homerun system can be designed around any site configuration. Its design is adaptable to work with wire hangers, cable trays, and trenching.

GLIDE Agile

Number of pieces: 7 Superstructure Beam Members (above the vertical leg)

Certifications: UL2703, Edition 1; CPP Wind Tunnel Tested

Installation: Our adjustable and durable frame features less hardware, integrated electrical bonding, and included wire management resulting in reduced labor hours. Installation times are shortened by up to 36% through simplified connections, agile parts, and seasoned field teams. Compatible with ground screws that will eliminate refusal risk, increase install efficiency, and make projects more predictable. With one of the most experienced field teams in the industry, we have priceless insights that allow us to overcome challenges and streamline processes to ensure projects are completed on time.

Advantages: With a slope tolerance of 36%, our racking can accommodate high slopes and undulating terrain. Landscape orientation is bifacial compatible to maximize potential backside power yield. Durable mechanics can tolerate wind speeds up to 170 mph and 100 PSF ground snow loads. Our seasoned field team prioritizes accuracy, safety, and efficiency. Foundation consultation from an unbiased partner, based on your unique project site. No matter the terrain or weather, we’ll provide the right solution. Our versatile design enables numerous configurations allowing us to meet your unique needs and bring solar to more fields.

GLIDE Wave

Number of pieces: 7 (1 foundation, 6 racking components & bracket assemblies)

Certifications: UL2703, Wind Tunnel Tested

Installation: Engineered with flexibility in mind, the design incorporates continuous rows to mitigate topographic changes and minimize the number of foundations required. The system can be altered to multiple foundation options, with the base option being driven piers. Proprietary electrical bonding is integrated into the racking system, as well as other solutions for wire management. Pre-assembled parts reduce the number of connections required to be made in the field, minimizing Installation time.

Advantages: The standard engineering of the system is designed to accommodate slopes up to 15%. With several GW deployed across all 50 states, the system is durable and robust enough to accommodate the heavy snow loads in the Northeast, along with the high wind speeds of Hawaii. Our team of professional designers, licensed engineers, and dedicated project management collaborates to ensure projects are delivered in an effective manner and able to operate efficiently. We design each system to site specific environments, helping our partners to maximize the return value on each opportunity.

GLIDE Fuse

Number of pieces: 7 (2 foundations, 5 racking components & bracket assemblies)

Certifications: UL2703, Wind Tunnel Tested

Installation: Designed with a low tilt and clearance, the dual foundation design supports a higher number of PV modules per foundation than standard fixed-tilt systems. The low clearance makes for easier access to assemble components, all of which contain one bolt size. Components are shipped to site pre-assembled, requiring less hours for assembly in the field.

Advantages: For flat sites with low wind and snow loads, this system helps to maximize the PV output with a high ground coverage ratio (GCR). The low tilt and low clearance of the structure reduces row spacing, allowing for more PV modules to be deployed in a given area. The number of racking components is also reduced, reducing the installation time required to assemble the structure. A proprietary design in the components bonds the system, helping make wire management less intrusive.

Carports

Surface lot canopy, Garage canopy

Product description: Terrasmart offers a variety of canopy structures to accommodate any parking surface including longspan, inverted, perimeter and aisle structures. Our structures and foundations are engineered for environmental loading and any subsurface/soil conditions. Accessory options such as water management, snow guards, facia trim, and multiple coating options are available. A big part of our value is our ability to work with our customers on the conceptual design phase to ensure the best possible system is designed for each project and budget.

Construction process: Pre-construction design identifies risk up front for smooth project planning. Smart scheduling and through bolt connections result in less disruptions on site and faster installation time. We’ll work with you to ensure installation is phased in the most efficient way possible.

Differentiator: Terrasmart provides a single source for design, engineering, manufacturing, and installation. With projects covering most of the U.S., we’ve completed projects from Massachusetts to Hawaii. Terrasmart has deployed over 270 MW of canopy systems ranging from 100 kW up to 14.8 MW. With over a decade of projects on the books, we have a long track record of delivering projects at every scale — on time and on budget.

www.terrasmart.com | info@terrasmart.com | Webinar coming April 24

Specialty: OMCO has six manufacturing facilities –in Arizona, Alabama, Indiana and Ohio – and can offer highly competitive pricing and the shortest lead times in the industry.

Total MWs installed in U.S. by year-end 2024: 11 GW

U.S. manufacturing footprint and capacity: OMCO Solar’s overall factory-direct manufacturing capacity is over 10 GW across its six facilities, encompassing more than 700,000 square feet of manufacturing space throughout the U.S.

Turnkey services

- On-site pile testing: This includes a third-party stamped report that can be used for foundation design, which is a cost-effective alternative to geotechnical reports.

- Precision Engineered — Engineering Design & Site Optimization. Can optimize a project design and customizable solutions to maximize the benefits of OMCO products.

Origin 2L Bifacial Factory-Direct Tracker

Posts per row: Dependent on soil conditions, type of posts and row length — average is 11 to 13 per row.

Row lengths: While 96 modules per row is most common, OMCO Solar can customize to accommodate up to 112. Unique bearing technology allows long straight rows — 4 strings when others can only mount 3 — fewer motors and controllers per MW.

Slope Tolerances: Up to 15% for a North-South Slope

Design: OMCO Origin 2L (2-in-Landscape) Bifacial Trackers are primarily constructed of galvanized steel and cast aluminum. Bearings include a wear surface composed of a unique long-life, low-friction, self-lubricating acetal blend. A balanced design allows for more accurate targeting and reduced energy consumption. Some subassemblies are factory preassembled and shipped as single units for labor, time and cost savings. The unique bearing adjusts to accommodate post misalignment. OMCO Origin 2L Bifacial Trackers are open on the back — no torque tube blocking the cells — for highest energy production. The height of the tracker is low — like 1-in-portrait trackers — to minimize installation labor. Foundation options include OMCO-produced driven C posts (preferred) and driven I or W posts, and ground screw foundations.

Advantages:

• Factory Preassembled: Some subassemblies are supplied as single, preassembled units for installation labor savings.

• Balanced Design: Axis of rotation at the center of mass of the table — improves targeting accuracy, increases energy production and minimizes energy consumption.

• Long Wear Life: Bearings tested to more than 40 years equivalent life.

• 7 Dimensions of Adjustment: Bearings adjust to accommodate post misalignment, avoiding project delays.

• Over 20% Higher Back Side Production: The open back allows uniform backside irradiance, which is critical for long cell and module life.

• Shortest Lead Times: Partners benefit from expedited delivery due to OMCO Solar’s four strategically located U.S. manufacturing plants. Lead times are typically 8 to 12 weeks.

Domestic Content: OMCO makes all structural components with domestic steel and is well positioned for IRA ITC benefits.

CHOICE Factory-Direct Fixed-Tilt

Number of pieces: 8 Typical Components + Hardware

Certifications: ISO 9001:2015 Standard, UL 2703 Ed. 1, CPP Wind Tunnel-Tested, NEC Compliant

Terrain Articulation: Accommodates up to a 20% grade change

Installation:

- For a pile-driven foundation, posts are driven into the ground.

- Pre-assembled tilt bracket assemblies are bolted onto the piles.

- Lateral beams are then connected by fasteners to the tilt assemblies.

- Modules are secured with fasteners directly onto the beams to provide a secure bond.

Advantages: Pre-Assembled tilt assembly optimizes packaging & shipping, reduces on-site labor requirements, accelerates total build time, and eliminates loose hardware along with third party grounding devices. This in turn accelerates the assembly process. All structural components are manufactured in OMCO Solar’s six U.S. manufacturing plant facilities. With the company’s factory-direct model and domestically sourced supply chain, OMCO Solar consistently delivers quality solar mounting solutions with the shortest lead times in the industry.

www.omcosolar.com | Sales: info@omcosolar.com

Company specialty: Whether the size of a project is 5MW or 500MW, distributed generation, or utility-scale—ARRAY trackers can meet all project requirements regardless of terrain or environmental conditions.

MWs installed in North America: Over 60 GW installed in North America, to date.

U.S. manufacturing footprint and capacity: ARRAY continues to invest in U.S. sourcing, including a recent $50M+ investment in a new manufacturing facility in Albuquerque, NM. We will offer 100% domestic sourcing in the first half of 2025 with our strategy focusing on partnering with proven U.S. suppliers, lowering logistics-related risks, and providing sourcing flexibility to meet the unique needs of each solar project.

DuraTrack and OmniTrack with SkyLink

Row length range: Up to four strings, 120 modules (up to 140 meters, module dependent)

Slope tolerances: N-S 8.5° standard with up to 15° optional (up to 1° slope change—1.75%-- in torque tube); E-W up to 30° combined angle

Certifications: UL 3703

Advantages: The ARRAY SkyLink Tracker System is a revolutionary tracking solution. We’re evolving our technology, pushing boundaries and building on the proven capabilities of the ARRAY DuraTrack and ARRAY OmniTrack platforms. This latest innovation includes an eight linked row architecture with passive wind mitigation, PV String powered brushless DC motor, Zigbee wireless communication, and a suite of ARRAY SmarTrack features. SkyLink maintains the leading benefits of DuraTrack and OmniTrack while offering greater flexibility and optimization. Grid independence ensures continuous operation and reduces extreme weather-related risks, such as hail and snow. Its streamlined design also provides high reliability and reduces costs related to trenching, wiring, and electrical supply needs, helping speed up installation and project schedules.

Unique software capabilities? ARRAY SkyLink tracker systems come with the full suite of ARRAY SmarTrack™ capabilities. SmarTrack is an innovative, simple, and secure software and control systems platform featuring multiple tools and capabilities to improve performance for DuraTrack, OmniTrack, and SkyLink systems.

- Improve project performance and maximize power production with Terrain Adaptive Backtracking and Diffuse Weather Response

- Reduce risks in extreme weather conditions with Hail Alert Response and Automated Snow Response

Specialty: With over 90 GW of smart solar trackers operational or under fulfillment around the world, Nextracker NX Horizon solar tracker systems are well-suited for both utility-scale and DG solar projects.

NX Horizon-XTR

![]()

Row length range: Configurable per module type, string length, and site layout

Slope tolerances: N-S site slope and E-W site slope up to 15%. N-S terrain following conforms to native land contours. Angular tolerance configured to site conditions.

Certifications: UL 2703, UL 3703, IEC 62817, CSA

How does it install? NX Horizon-XTR all-terrain solar tracker delivers enhanced yield while minimizing environmental impact on project site. Its independent-row, balanced tracker design and software solutions enable deployments in all geographies, sizes, and most terrains—from flat sunny and rectangular sites to irregular more diffuse and undulating locations. The NX Horizon platform allows EPCs to conform to sites with irregular and rolling terrain layouts and can eliminate the need for additional grading, lowering costs, and using space more efficiently while helping to boost energy yield and financial returns for both utility-scale and DG project owners. The latest version, XTR-1.5, doubles XTR’s ability to conform to sloping terrain, further expanding opportunities for solar development on challenging sites.

Advantages: NX Horizon-XTR, a new variation of the industry-leading smart solar tracker NX Horizon, conforms to the natural terrain, generating a series of benefits, such as:

- Eliminating cut-and-fill earthworks

- Reducing pier lengths

- Easing permitting

- Softening environmental impacts

This new smart solar tracking system also contributes to accelerating project construction schedules that help save time and money.

Unique software capabilities? When combined with its flagship NX Horizon solar tracker platform, Nextracker’s TrueCapture yield optimization and control software forms a powerful combination that can boost performance, save cost and maximize return for project developers and asset owners. TrueCapture combines advanced sensors, weather forecasting, and machine-learning technologies to maximize energy generation for new and existing solar power plants. The software’s intelligent, self-adjusting tracker control and yield optimization system boosts solar power plant production by continuously optimizing the tracking algorithm of each individual row in response to site features and changing weather conditions.

Company specialty: Solar tracking solutions engineered from-the-ground-up for challenging terrain, combining innovative hardware architecture and an advanced terrain-aware controls package to enable zero-grading solar development.

MWs installed in North America: 1.3 GWs operating and being installed

U.S. manufacturing footprint and capacity: We offer a domestic content qualified (US supplied) tracker with 100% of our steel available from US sources. Domestic suppliers are in Texas, Arizona and California. Coupled with available international supply chain options, our total capacity is 3GWs annually, with an anticipated 50% growth in 2025.

TRACE All Terrain Tracker

Row length range: Typically designed with three string row lengths but can be customized to project design

Slope tolerances: 37% Max N/S Slopes and 15 degrees of articulation for undulating terrain at every post. This is our bread and butter and based on your list, best in class.

Certifications: UL 3703, IEC 60529 IP65 (Row Controllers)

Advantages: With industry-leading slope tolerance up to 37% and articulating couplers allowing 15 degrees of movement at each post, TRACE’s ability to handle undulating terrain (peaks and valleys of natural topography) is unmatched by any other tracker. These same features that allow flexibility on terrain also enable the fastest installation times in the industry as validated by a 3rd party study. Our comprehensive structure, controls, and optimization software package work together seamlessly to deliver higher energy yields on challenging sites while reducing total project costs.

Unique software capabilities?

- Terrain Aware 3D Tracker Schedules – the system accounts for the terrain underneath the tracker with a site-specific rotation schedule to minimize row-to-row shadowing. There are other energy optimization features such as diffuse boost, split-cell backtracking included. These advanced features are provided to all customers at no additional cost.

- The Battery Management System provides enhanced protection for extreme cold weather conditions.

Company specialty: A value-added distributor of utility-scale solar equipment that offers the industry’s top solar tracker technologies and eBOS goods supported by a suite of project enablement services.

MWs installed in North America: 6.3GW/6,392 MW

Turnkey services: Design, structural engineering, procurement/supply, mechanical installation, and specialty services to EPCs, developers, and municipal utilities.

eBOS solutions

Solutions: DC collection, wire management, and MV cable and accessories.

Basics: We streamline the eBOS procurement process with a “one-stop-shop” approach to electrical supply.

Key features: Our partnerships with the industry’s leading brands gives us the ability to extend our focus on design, constructability, and customer success to the electrical balance of plant. Our end-to-end solutions allow you to work with one passionate supply chain partner instead of a patchwork of generalist distributors.

Installation explained: With high volumes of on-hand inventory, our solutions reduce lead times and provide certainty to customers with tight construction schedules.

Are there racking/tracker partner integrations or brand-specific versions available? If yes, list them: Our solutions support both Array Technologies and Nextracker systems.

Array Technologies DuraTrack

Row lengths: 100+ module row lengths, up to 126 meters long (varies based on module size and weight)

Slope tolerances: 15 degrees N/S; 37 degrees E/W

Certifications: UL 2703, 3703 and IEC 62817

Design: The Array tracker can be custom designed, supplied, and installed by Ampacity Renewables, Array’s trusted partner and leading Array tracker installer. Ampacity Renewables is dedicated to offering customers the best overall experience, with a team of over 300 tracker experts to offer support. Linked rows are powered by an AC motor, an articulating driveline, and a rotating gear drive. Up to 32 rows can be controlled by just one motor.

Advantages: The DuraTrack boasts up to 25% energy gain over fixed-tilt systems and has an unparalleled track record of high uptime (99.996%), 7% lower LCOE, and 31% lower lifetime O&M with zero scheduled maintenance. The Array tracker utilizes the fewest motors per MW, with 167 times fewer components, and is the most adaptable tracker in terms of terrain, with low grading and the ability to be readily deployed on the most challenging parcels. In addition, the tracker is designed to mitigate high wind loads, snow loads, and inclement weather like hail.

NX Horizon by Nextracker

Row length range: Configurable per module type, string length and site layout.

Slope tolerances: Up to 15% N-S and 15% E-W

Certifications: UL 2703, UL 3703, IEC 62817, CSA

How does it install? With pre-assembled components, no drive linkages, no AC wiring, self-aligning rails, and available XTR terrain following upgrades, NX Horizon is fundamentally faster to install, requiring less construction labor, less grading, and less total project capital cost.

Advantages: NX Horizon’s patented independent row, self-powered tracking system provides reliable performance across the widest possible range of site conditions. Simple, robust hardware, including self-aligning module rails and vibration-proof fasteners, enables rapid installation and long life without maintenance. Mechanically balanced rows minimize tracking power requirements and pair with a time-proven, rugged drive and control system for maximum durability and uptime. NX Horizon’s decentralized architecture with intelligent communications supports maximum layout adaptability, flexible construction and commissioning sequencing, advanced tracker functionality, and over-the-air updates.

Unique software capabilities? TrueCapture combines advanced sensors, weather forecasting, and machine-learning technologies to maximize energy generation for new and existing solar power plants. The software’s intelligent, self-adjusting tracker control and yield optimization system boosts solar power plant production by continuously optimizing the tracking algorithm of each individual row in response to site features and changing weather conditions.

Company specialty: Polar Racking specializes in utility-scale and commercial ground-mount solutions, single-axis tracker, fixed tilt, solar carport, agrivoltaics and a wide range foundation solutions, coupled with a suite of engineering collaboration tools, technical services and installation support.

MWs installed in North America: 4 GW

U.S. manufacturing footprint and capacity: Polar Racking has three manufacturing facilities in the US and we’re continuing to expand our manufacturing worldwide.

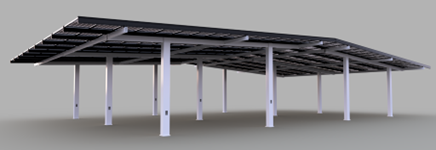

Shield solar canopy

Shield is a solar carport mounting solution that is highly configurable, easy to assemble and cost effective. With single, double, and long-span options, it’s the industry`s most versatile solar carport solution.

Custom-designed solar carport mounting solution tailored for all types of parking lots. Available in single and double configurations, as well as long span setups, to optimize system size. Choose from various configurations including L-shape, T-shape, Y-shape, Pi-structure, Long Span, and Check Mark structure. Additionally, our solution includes water management and snow guards for enhanced functionality and durability.

Also, Polar offers comprehensive engineering services to tailor the Shield system to specific project requirements, ensuring structural integrity, durability, and concern for the environment.

SOL-X 20/25 Tracker Control System

Basics: The SOL-X 20/25 Electrical Package provides comprehensive guidelines for the electrical and communication aspects of solar tracker systems. It covers network communication protocols, electrical requirements, and UPS sizing considerations to ensure optimal performance and safety.

Installation explained: Installation of the SOL-X 20/25 Electrical Package involves setting up wired and wireless communication protocols between Tracker Control Units (TCU), Remote Sensing Units (RSU), and Network Control Units (NCU). Additionally, it includes sizing and installing backup power supplies (UPS) and adhering to local electrical codes and regulations for interconnecting the tracker control system.

Key feature: A key feature of the SOL-X 20/25 Electrical Package is its detailed guidance on sizing UPS systems to ensure uninterrupted power supply during emergencies. It offers options for distributing power efficiently across the site, balancing load requirements and minimizing cable sizes. The package emphasizes the importance of compliance with local regulations and safety standards to optimize system performance and reliability.

Company specialty PV Hardware (PVH USA), founded in 2011, is a leading solar tracker manufacturer and provider of innovative solar tracking solutions for the global solar energy market.

MWs installed in North America: 3,100MW in solar projects in North America

U.S. manufacturing footprint and capacity: In Spring 2024, PVH USA opened one of the largest U.S. solar tracker manufacturing facilities in Houston, the company’s third manufacturing facility worldwide. The 50,000-square-foot, $30 million facility is dedicated exclusively to manufacturing solar structures and trackers and will help lead the country’s rapidly expanding solar power generation infrastructure.

AxoneDuo Infinity

Slope tolerances:

- N-S: up to 15%

- E-W: up to 15% in linked row / unlimited in unlinked

Certifications: UL 3703, IEC 62817

Advantages: The AxoneDuo Infinity solar tracking solutions is specially designed to improve adaptability to any terrain. AxoneDuo has the lowest number of motors and controllers per string on the market and allows for a large number of combinations to adapt to any configuration: linked or unlinked, with 2, 3 or 4 strings per row. AxoneDuo is the ultimate solution for terrain of any contour or elevation. In addition, AxoneDuo Infinity reduces the number of man-hours on site to a minimum. Thanks to PVH's pre-assembly service, some parts arrive pre-assembled from the factory, saving up to 44% of field labor hours.

Unique software capabilities? AxoneDuo integrates with PVH USA’s ProInsights SCADA software, an all-in-one SCADA for remote monitoring, control, analysis and maintenance of a solar tracking system. ProInsights is specially designed for operators and plant managers to provide real time operational visibility of the tracking system as a top priority, facilitating and making the system maintenance more efficient and reliable. In addition, PVH USA has introduced solar tracking software innovations like the Diffuse Control algorithm, which enables increased energy collection during overcast days while minimizing motor energy consumption.

Cable and wire management

Company specialty Above-Ground Cable Management delivers safe, strong and durable support for all types of wiring for utility-scale, ground-mount solar projects.

MWs installed in North America: 120+ GW

U.S. manufacturing footprint and capacity: CAB Solar is manufactured by individuals with disabilities at two manufacturing facilities in western Pennsylvania. Nearly all of the components for CAB Solar’s patented above-ground cable management systems are sourced from Pennsylvania, Ohio and Tennessee. CAB Solar has continued to expand its manufacturing capacity to meet the increasing demands of the solar industry.

Above-Ground Cable Management with Integrated Grounding

Material: CAB Solar’s Above-Ground Cable Management System with Integrated Grounding uses a specially engineered grounding messenger wire strong enough to provide support functionality and evaluated to be conductive enough to serve as an Equipment Grounding Conductor (EGC) and a Grounding Electrode Conductor (GEC) with #3, #2 & #1 equivalents available. CAB Hangers are manufactured from Class 3 galvanized, high tensile strength spring steel for maximum strength and corrosion resistance. All hangers receive a thick PVC coating that provides added safety and protection for cables. The high-performance coating is applied on 100% of the surface which makes hangers totally insulated and durable in highly corrosive environments.

Installation: Installation of the patented CAB Solar Above-Ground Cable Management System is quick, simple, and straightforward in all types of utility scale projects. CAB Solar is appropriate for tracker, ballasted, and fixed projects. CAB Solar’s easy installation provides a far more predictable cost than any other cabling system.

Key Features: CAB Solar’s Above Ground Cable Management System with Integrated Grounding revolutionized the cable management industry and is proudly manufactured in the USA by persons with disabilities at the Cambria County Association for the Blind and Handicapped.

Messenger Wire

Key Feature: CAB Solar’s uniquely engineered grounding messenger wire, made of a copper-clad steel composite, is strong enough to provide support functionality and evaluated to be conductive enough to serve as an Equipment Grounding Conductor (EGC) and a Grounding Electrode Conductor (GEC) with #3, #2 & #1 equivalents available.

Mid Pier Bracket

Key Feature: CAB Solar’s durable Mid Pier Bracket made of galvanized steel and hardware with a tin-plated bronze grounding clamp provides a clear and sturdy path for grounding in any type of utility-scale project. CAB Solar’s patented Integrated Grounding System is safety listed to UL 2703 by Intertek.

Torque Tube Hangers

Installation: CAB Solar's Multi-Carrier Torque Tube Hangers for under-panel cable management offer a tight, snap-on fit over most torque tubes or fixed tilt structures. The low profile is especially beneficial for reduced shadowing with bifacial panels. The innovative spiral design holds large bundles of cable safely and securely, while simplifying upgrades, maintenance and troubleshooting.

Key feature: CAB Solar Products are manufactured in the United States by the Cambria County Association for the Blind and Handicapped. This non-profit provides numerous services as well as employment opportunities for over 350 persons with disabilities in Cambria County, Pennsylvania. Purchase of CAB Products helps support this mission.

Customizable Cable Management

Key Feature: CAB Solar offers a variety of innovative solutions for your cable management needs. Not all solar projects are “one-size fits all” designs. CAB’s team of proficient engineers and experienced solar project developers can assist you to customize solutions for your utility-scale projects.

Company specialty: AWM’s utility-scale solar and BESS Cable Management Systems (CMS) are optimized for ampacity, durable, cost-effective, and rapid to install.

MWs installed in North America: 20+ GW and 350 + projects globally, with the average large scale power plant totaling 200+ MW

U.S. manufacturing footprint and capacity: AWM works with manufacturing vendors across the U.S. to produce and deliver our Cable Management Systems (CMS) and supporting products at multi-gigawatt scale.

Bonsai Module Cable Hanger

Material: Every component of the AWM Bonsai Cable Hanger is made of exceptionally durable alloys and is free of polymeric material, with a life expectancy exceeding 40 years. The products, which are certified under UL1565, can withstand all weather conditions: temperatures from -40°C to +150°C, extreme ice and snow loads, and worst-case corrosive environments.

Install: AWM offers the Bonsai Cable Hangers in a variety of flavors, including bifacial-friendly hangers which are mounted near the torque tube on module clamps and can be installed prior to module installation. Installation is typically performed with one hand, enabling a faster installation of hanger and cable. Bonsai meets all the latest requirements in the industry; additionally, AWM provides a highly detailed drawing set which will guarantee golden row approval.

Key feature: Bonsai Cable Hangers are highly customizable and tailored, so regardless of the tracker or module type, we offer the most competitive value-engineered offering on the market. In addition, thanks to our strategic and nuanced design, our solutions also help the installer reduce time and costs. For example, if the Bonsai Cable Hanger is on the clamp of the tracker, our unique design ensures installation velocity, and results in less cabling needed on the site. In short, AWM Bonsai Cable Hangers ensure lower costs with less cable hangers needed, and a more efficient, cost-optimized option for installers and developers.

Solar LOTO

Material: AWM’s Solar LOTO is a made of a UV Stabilized Polycarbonate plastic and is reusable from project to project.

Basics: AWM’s single part locking dust cap is OSHA compliant and serves as both a safety LOTO device and a dust cap during energization or maintenance. Designed to be dust and water resistant and certified to IP67D, the Solar LOTO ensures safety while protecting against environmental contaminants.

Installation: The Solar LOTO installs rapidly and easily. The device attaches directly to the connectors and requires a special disconnect tool to remove it. This significantly decreases the risk of accidental electrocution during energization and maintenance.

Key feature: AWM’s Solar LOTO is a groundbreaking product designed to enhance safety and prevent accidental energization of string or feeder cables. Unlike typical dust caps that can easily fall off, this long-term dust cap locks securely onto the connector, ensuring maximum protection against dust and other contaminants. Additionally, the Solar LOTO can prevent super strings, a phenomenon that can occur when too many solar panels are connected in series. With its innovative features, the AWM Solar LOTO is revolutionizing the solar industry and setting a new standard for safety and reliability.

Racking/tracker partner integrations: The Solar LOTO is compatible with any MC-4-compatible cable coupler.

PHOTON Toolkit

Material: AWM’s PHOTON Toolkit is comprised of several unique tools.

Basics: AWM’s PHOTON Toolkit includes the tools, methodology, and expert guidance to streamline construction and cut down on labor costs during messenger cable install, while also reducing cable sag.

Installation: The PHOTON Toolkit utilizes a calibrated scale and winch to achieve end-to-end tensioning of the messenger cable based on temperature-agnostic guidelines The methodology unlocks the ability to install and tighten thousands of feet of messenger cable with a crew of 2-3 in minutes, significantly reducing traditional messenger cable installation times.

Key feature: Traditionally, above-ground wire cable management systems (CMS) have required the installation and tensioning of thousands of feet of messenger cable one pile at a time - a lengthy process that requires regular references to temperature-dependent sag charts. AWM’s safety-first approach diminishes the potential for cable snap or human error. With the PHOTON Toolkit, installers can forego sag charts while also increasing the safety and precision of messenger cable tensioning.

HELIOS Beam Rod

Material: The HELIOS Beam Rod is made of exceptionally durable alloys and is free of polymeric material, with a life expectancy exceeding 40 years. The beam rod can withstand all weather conditions: temperatures from -40°C to +150°C, extreme ice and snow loads, and worst-case corrosive environments.

Basics: HELIOS Beam Rod is a messenger cable support component with significant technical advantages for installers. With a moment of capacity of 14,000 inch-pounds, HELIOS is stronger, more scalable and more corrosion-resistant than its predecessors.

Installation: The HELIOS Beam Rod features a simple and secure installation process. The beam rod is compatible with multiple pile types and can be attached using a simple screw. It can also be adapted to attach to cylindrical piles using a U-bolt system.

Key feature: The HELIOS Beam Rod and all of its sub-components are domestically manufactured, highly customizable and available in various lengths. HELIOS enables AWM’s cable management system (CMS) to accommodate angled runs and terrain challenges, making it a cost-effective and practical solution for utility-scale solar projects on complex or uneven terrain.

SUMAC Rail

Material: The SUMAC Rail is made of exceptionally durable alloys and is free of polymeric material, with a life expectancy exceeding 90 years. The SUMAC Rail can withstand all weather conditions: temperatures from -40°C to +150°C, extreme ice and snow loads, and worst-case corrosive environments.

Basics: The SUMAC Rail is compatible with AWM’s Arden Hangers and Pinyon Hangers. It provides optimized wire management for clustered disconnect boxes, ensures uniformity, and eliminates the need for cable trays. It is a sag-free alternative to messenger cables, specifically engineered for utility-scale solar and BESS projects.

Key features: The SUMAC Rail, a supporting product for AWM’s CMS, enables a reduction of the total pile count around disconnect clusters while ensuring uniform cable arrangements, which cuts down on overall project steel costs. A sturdy aluminum alloy beam helps the CMS navigate tracker drive lines safely and eliminates the risk of increased cable sag during hot weather. SUMAC can easily accommodate additional loads, does not require end posts, and it replaces the cable tray, cable ties and cleats that are required with these arrangements. Its unique design removes the need for additional pile placement around disconnect clusters and drive lines.

Installation explained: AWM’s Arden Hangers and Pinyon Hangers can be firmly attached to the SUMAC Rail using the same single-crimp process that these hangers are known for, allowing for seamless integration. The SUMAC Rail itself attaches directly to preexisting piles and structures, eliminating the need for additional or altered pile placement around combiner boxes and drive lines. It is designed to simplify the installation process as well as reduce the number of end piles required for a project.

Are there racking/tracker partner integrations or brand-specific versions available? If yes, list them: Customization options, backed by AWM’s professional support team, are available for the SUMAC Rail as well as for the entire product suite.

Pinyon Hanger

Material: Pinyon Hangers are certified under UL1565, UL2239 and UL2703. These all-metal hangers are free of polymeric material, with a life expectancy exceeding 90 years. Pinyon Hangers can withstand all weather conditions: temperatures from -40°C to +150°C, extreme ice and snow loads, and worst-case corrosive environments.

Basics: Pinyon Hangers are part of AWM’s efficient, cost-effective CMS for North-South and East-West trunk bus systems. Their asymmetrical structure supports the messenger cable directly at the piles, eliminating the need for support brackets. This reduces material, labor and moment-load on piles, and minimizes the required area to accommodate a CMS.

Key features: Pinyon Hangers provide a much-needed solution in specific site conditions and layouts, especially in North-South tracker CMS designs. Its versatile application extends beyond trackers to include fixed-tilt mounting systems, further demonstrating its adaptability in various utility-scale solar configurations. Integrated into the larger Electrical Balance of System (eBoS), the Pinyon Hanger plays a crucial role in supporting the increasing trend of North-South tracker and East-West fixed tilt trunk bus designs, given lower DC voltage drop and improved O&M access. By working closely with eBoS trunk bus cable providers, AWM ensures that the Pinyon Hanger contributes to achieving excellence in these designs.

Installation explained: The Pinyon Hanger features an innovative single-sided design with a simplified installation approach. It supports the messenger cable directly at the pile, reducing both the costs and space required for the hangers. Since the Pinyon Hanger is installed directly on to pre-existing piles, the substantial costs and time typically associated with solar cable management installation are significantly reduced. Pinyon Hangers can be connected to the messenger cable with a simple crimp, which saves valuable labor hours, providing a superior hanger solution compared to competitor systems.

Are there racking/tracker partner integrations or brand-specific versions available? If yes, list them: Customization options, backed by AWM’s professional support team, are available for the Pinyon Hanger as well as for the entire product suite.

Material: Every component of the AWM Hail-Stow Hanger is made of exceptionally durable alloys and is free of polymeric material, with a life expectancy exceeding 90 years. They can withstand all weather conditions: temperatures from -40°C to +150°C, extreme ice and snow loads, and worst-case corrosive environments.

Basics: AWM’s Hail-Stow Hanger is a first-of-its-kind hanger built for the industry’s leading defensive hail stow tracker technologies: Nextracker’s Hail Pro-75. The Hail-Stow Hanger integrates seamlessly into the Nextracker system, allowing developers to adopt a 75-degree stowed tilt angle which greatly reduces the risk of hail module breakage.

Key features: The Hail-Stow Hanger delivers the same level of ampacity optimization as AWM’s Arden and Pinyon Hangers, while providing hail mitigation benefits and supporting a 75-degree tilt capacity. It is specifically designed to fit within the tight gap that is formed from Nextracker’s Hail Pro-75 and the Damper Bracket. AWM’s Hail-Stow Hanger minimizes flood plain clearance issues due to its unique shape. At Non-Damper Piles, the Hail-Stow Hanger mounts directly to the pile flange, allowing high placement to eliminate any flood plain clearance concerns.

Installation explained: AWM’s unique, asymmetrical Hail-Stow Hanger is installed directly on to pre-existing piles. This means that both the costs and the time needed for utility-scale solar power plant installation are greatly reduced. The single-sided Hail-Stow Hanger is connected to the messenger cable with a simple crimp, which saves valuable labor hours and ensures developers and EPCs complete their projects on schedule.

Are there racking/tracker partner integrations or brand-specific versions available? If yes, list them: The Hail-Stow Hanger is customized for Nextracker’s Hail Pro-75.

Company specialty: Snake Tray is a US manufacturer of cable management solutions for PV/Solar, Battery Energy Storage and EV Charging designed to save on labor and materials.

MWs installed in North America: 35+ GW

U.S. manufacturing footprint and capacity: Snake Tray has been designing and manufacturing cable trays for over 29 years. We have unlimited capacity in our state-of-the-art facilities. We design and manufacture end-to-end cable management solutions utilizing our 29 years of expertise in providing innovative solutions across the globe for leading corporations and organizations in a wide variety of industry sectors including Renewable Energy, Transit, Datacom and Electrical.

Solar Snake Max XL

Solar Snake Max XL manages cables ranging from 350 Kcmil up to 1250 Kcmil from the module to the interconnection area. This trenchless solution installs as fast as 22,000 feet in a day offering a safer, less labor-intensive solution. The open-air design maintains NEC 310.15 compliant cable separation which allows the cables to operate more efficiently to yield up to 30-watt hours per meter far surpassing that of bundled cables. The above ground design also allows for easy installation, operation and maintenance.

Hard Rail System Benefits

Using the same elements from the messenger wire system the cables are fixed in a structural containment allowing the free air routing in and around the invertor pad, as well as a complete routing system for battery farms.

- Maintains NEC 310.15 compliant cable separation which can yield up to 30-watt hours per meter more energy than bundled cables

- No trenching for safe installation, operation and maintenance

- No derating of cable required with open air design

- Easy snap together components require no field fabrication

- Accommodates cables ranging from 350 Kcmil up to 1250 Kcmil

- Mounts to any style of vertical pilings or poles

- Install in any elevation or terrain

- Insulation-Piercing Connector (IPC) compatible

Solar Snake Max XL for BESS

Basics: Cable Management For Interconnecting the Batteries to the Inverters, Utility or Solar Farm

Benefits:

- Open air design means no trenching, substantially lowering the cost of labor and materials

- NEC 310.15 code compliant cable separation requires no derating of the cables, allowing cables to operate more efficiently

- Snap together components require no tools

- Accommodates cables up to 1250 Kcmil

- Compatible with any inverter style and battery storage system

- Optional hard rail system with wings has isolating cable paths for fiber optic and battery control cables

LV Module Benefits:

- Design optimized to carry Low-Voltage cables from Battery to Transformer LV Cabinet

- Available in 2-hour and 4-hour battery configurations

- Trefoil cleats designed to 135kA Resistance to Electromechanical Force (Short Circuit)

- Can be configured to accommodate multiple equipment grounding conductors and Roxtec bushings

- Incorporated rodent ingress mitigation

MV Module Benefits:

- Design optimized to carry Medium-Voltage cables from one transformer to the next

- Can be configured to carry a range of MV wire cable and quantities

- 25kA Resistance to Electromechanical Force (Short Circuit)

- Incorporated rodent ingress mitigation

- Allows for Free Air separation of conductors, no bundle derates required

Solar Snake Max™ for Overhead Transportation of Auxiliary and Communications Circuits

- Our patented Snake Max and Snake Max XL Messenger Wire systems can be carried across BESS containers via ISO 1161 corner casting attachments

- Utilizing the ISO 1161 corner casting as an attachment point means no penetration or fastening to the BESS is required

- All of the benefits of Snake Max including Free Air Separation can be applied

- Compatible with multi-conductor branch circuit feeder cable and IPC/Trunk Bus applications

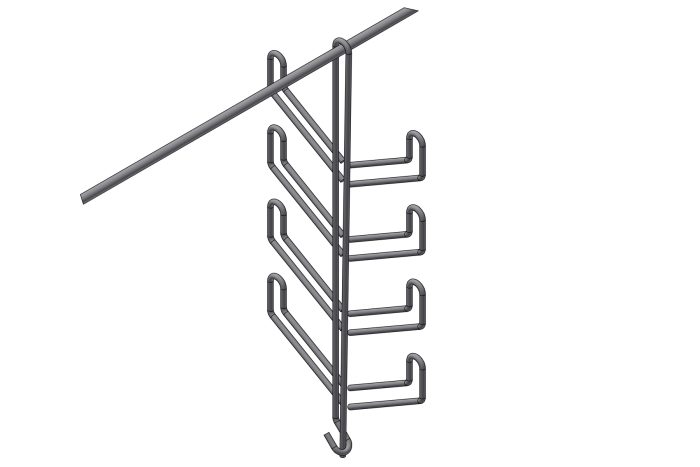

Cable Hangers

String and Feeder Cable Hanger

As utility grade systems grow in size so does the size of string cables. Utilize Snake Tray’s tree hanger with a capacity of up to a quantity of 16, 750 Kcmil cables per hanger. Ideal for larger scale projects and can even be stacked to create a modular system to further increase capacity. The side loading feature offers quick access to installing and maintaining cables for reduced labor costs. No trenching for minimal ground disturbance. The large capacity loops will handle any size of cable bundle easily and effectively.

String Cable Hangers for Messenger Wire

The new portfolio of solar cable hangers provides durable, cost effective, and expeditious installations for managing cables under solar panels. Our new hangers will greatly simplify new project installations, repowering, system expansions, upgrades, O&M, and troubleshooting over the life of the project.

Snake-Loc String Hanger

Material: Stainless Steel or Powder Coat

Basics: Snake-Loc is a dual pocket cable manager with a squeeze lock to secure to the messenger wire.

Key features: The Solar Snake-Loc Hanger is designed to securely carry bundles of string cables and feeder cables from rows of solar panels to a combiner box, the hangers attach to suspended tensioned messenger wires. The patented dual pockets offer an enclosed loop to contain and support string cables, plus an open side pocket to allow for multiple egress points of cables along the run. The hangers are held securely in position on the wire by the force of the squeeze lock. This maintains the NEC-required spacing of two-foot intervals for cables smaller than 350 Kcmil, yet still provides sufficient support and flexibility against wind and other forces of nature.

Installation explained: The top loading design allows installers to quickly drop cables into the hanger loop. The squeeze lock feature attaches to messenger wire in seconds without tools or training, dramatically cutting the time and labor costs of installing cables.

Torque Tube Hanger

Material: Galvanized, Stainless Steel or Powder Coat

Basics: Quick snap-on torque tube hanger with single pocket. Can work with any style of type of torque tube.

Key features: Quick snap-on torque tube hanger with single pocket. Can work with any style of type of torque tube. Multiple sizes are available. Stainless Steel or Powder Coat models available.

Installation explained: Simply attach the torque tube cable manager top the torque tube. No tools required.

Solar Mega Snake for Brownfield Sites

Material: Powder coated or stainless steel

Basics: Pre-fabricated cable tray with straight, turns. Ts and crossing grids for rooftop and brownfield sites.

Benefits:

- Pre-fabricated straights, turns, Tees and crossings

- Built-in mounting rail for attaching accessories including combiner boxes

- Variety of mounting options to accommodate any type of roof or ground mount installation

- Nests together for economical shipping and easy material handling

- East to install cable tray covers available

Available in Stainless Steel or Powder Coat for climate specific applications

Specialty: Gripple designs and manufactures a range of solutions for utility scale solar projects providing faster installations, material savings, logistical benefits and reduced project CO2. The Gripple solar offering includes above ground cable management systems for EBOS as well as a range of lightweight bracing and anchoring kits for ground-mount solar array installations and remedial works.

Power-Tie

Basics: Power-Tie is Gripple's wire cable tie. Engineered for lasting performance, Power-Tie combines the robust strength and endurance of steel banding with the ease of install and versatility of cable ties.

Material: Power-Tie’s wire joiner is manufactured from Zink Alloy and includes corrosion resistant Sintox Ceramic wedges. The wire rope is 316 stainless steel and the cable protection strap is made from HDPE with UV and FR additives. It is tested for -40 to +194 Degrees Fahrenheit (-40 to +90 Celsius) and has been designed to last 20+ years).

Installation: Place the strap over the cables then insert wire rope into the entry channel while holding the cables in place. Pull the wire rope tight until cables are secure and use the retention clips to secure any excess tail wire. Use the Flag Key to release the GripTie allowing for adjustment or re-installation.

Key features

- Simple Install – As easy and fast as a traditional zip tie

- Reduced Replacement Costs – Designed to last 20y+

- Use Anywhere – with 3 size options you can use on any type of structure

- High Strength – Comparable with steel banding and ties giving you confidence to use anywhere

- No Waste – 3 size options with no need to cut excess wire on site

- Safe To Install – Tool free with no RSI risks

CableSmart: Above Ground Cable Management

Gripple’s CableSmart above ground cable routing system is super quick to install, designed to last the lifetime of your site, and helps protect your cables from abrasion and wear. Gripple’s Messenger Kit is the fastest and easiest to install on the market thanks to the Dynamic wire joiner/tensioner. Alongside this, Gripple also supply messenger brackets and a range of hangers featuring side cable loading for easy installation and access. Gripple’s hangers have been specifically designed to protect cables, with a wide surface area to prevent pinch points and abrasion over time. The snap on locking mechanism which attaches hangers to the messenger wire also prevents movement, ensuring hangers and weight remains evenly spaced long term.

Materials: All materials are designed to last 30 years +, and are tested between -40 and +90 degrees Celsius. Hangers are made from UV stabilized Polycarbonate, with the messenger wire made from corrosion-resistant Zinc Aluminum.

Installation: Installation is quick and simple, requiring just hand tools and minimal training. First contractors install the Messenger Kit which can be attached to end posts using eyelet fixings or intermediate ground mount frames using the Messenger Brackets. The Messenger Kit is quick to tension using the Gripple Dynamic tensioner, making the system so much faster than traditional turnbuckles. Once the Messenger Kit is secure, contractors can attach the Hangers at regular intervals along the messenger wire. The Hangers feature a locking side loading gate which makes loading cables easy and O&M access simple.

Solar Ground Anchoring Kits

Material:

- Anchor head: Zinc-Aluminum alloy or Aluminum Alloy

- Wire Rope: Steel (zinc-aluminum coating)

- Dynamic tensioner: Zinc alloy (ZA2)

Basics: Gripple’s game-changing ground anchoring products overcome real world on-site challenges and are ideal for supporting existing foundations and rectifying misaligned structures.

Quick and easy to install using just hand tools, Gripple Ground Anchoring Kits are strong and lightweight, delivering impressive performance up to 2,750 kg | 6,060 lbs. Available in convenient kits for easy handling, Gripple Ground Anchoring Kits deliver savings in terms of on-site logistics and off-site haulage.

Key features:

- High performance - Up to 2,750 kg | 6,060 lbs anchor performance (depending on anchor and soil type)

- Fast and easy - Install in minutes using just hand tools with minimal training

- Versatile - Acts as both primary foundation or as a support to existing piles or ballasts

- Reduced materials - Our products can have a positive impact on your bill of materials vs traditional solar foundations

- Strong and dependable - Developed using corrosion resistant materials to last over 30 years

- Undisruptive - Minimal ground and soil disturbance during and after installation

Installation: Gripple Ground Anchoring Kits are designed to be quickly and easily installed by hand in minutes, ensuring safe and secure installation of solar sites on previously unusable land. Simply drive the anchor into the ground at the desired depth. Next, tighten the wire to apply tension and rotate the anchor head, so the load bearing surface is parallel to the ground surface. The wire is further tightened to compress the soil above the anchor’s bearing surface. This compression transfers towards the surface to form a cone of soil which prevents further anchor movement – adding additional stability and peace of mind.

Solar Bracing Kits

Gripple engineers have developed a lightweight solar frame bracing kit which provides comparable structural performance to heavy traditional steel bracing, at a fraction of the cost. By replacing heavy steel cross sections with strong but lightweight wire rope bracing, you can significantly reduce material, transportation, and logistics costs, as well as embodied CO2. In addition, Gripple bracing kits are fast and simple to install using just hand tools, and are delivered in small boxes making on-site material handling easy compared with lengths of steel and powered machinery.

Material: All components are made specifically for outdoor use with a life expectancy of 30+ years in the harshest conditions. Gripple’s wire rope is coated with corrosion-resistant Zinc Aluminum and can be integrated as part of the frame with custom hot dipped brackets, or looped around existing fixing points. The internal gripping mechanism consists of a sintered ceramic roller offering a superior strength to alternative tension-only bracing systems, with a load rating of up to 3,860 lbs.

Install: The two-way locking device known as a PV Dynamic Tensioner allows you to install a brace quickly and easily between two piles. Applying pre-tension using a fast and unique tensioning tool, the PV Bracing Kit will ensure the frame stays rigid, eliminating misalignment that might occur due to external forces and environmental loads. The ready-to-use kits are fast and lightweight, drastically improving health and safety on-site.

Key feature: Kits come in oversized lengths to allow for greater flexibility in the tolerance of frame installation and to support a greater variety of mounting systems. To aid the installer, the Dynamic Tensioner component is releasable, allowing the product to be adjusted prior to tensioning.

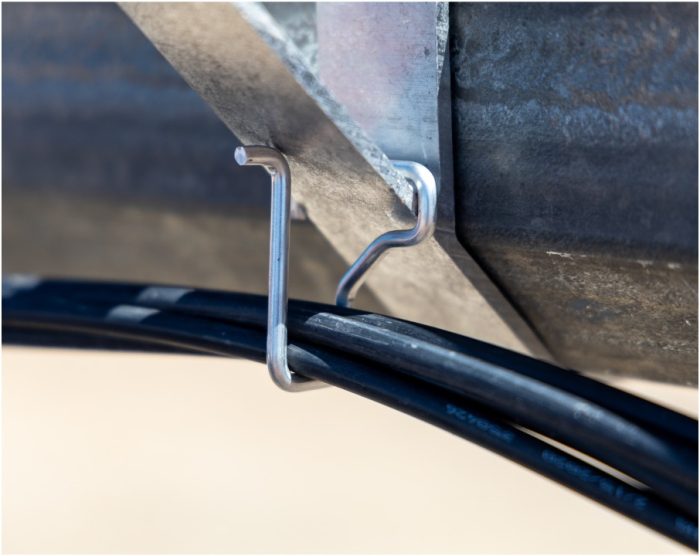

Solar Cable Bridge

Material: DX51D mild steel

Basics: Safely and securely manage string cables over tracker bearings or motors using our easy to install Solar Cable Bridge. Designed for simple, tool-free installation with minimal training, the Gripple Solar Cable Bridge prevents damage to string cables from moving tracker motors or bearings, eliminating costly cable damage and reducing downtime. Offering the ultimate versatility, the Solar Cable Bridge can be used in conjunction with Gripple Power-Tie, which comes with an unrivalled 20-year warranty, or any other standard cable tie.

Key features: Made from durable, corrosion-resistant steel, the Solar Cable Bridge is engineered to last more than 30 years, even in harsh outdoor conditions. Where downtime and site failures due to poor cable management can cost developers hundreds of thousands of dollars every year, this is an invaluable solution.

- Array Technologies Approved fixing strap

- Malleable hand install torque tube fixing strap

- 9.5 in bridge length

- Designed to prevent cable damage and wear

- Hex nut fastening

- Designed for use with Gripple Power-Tie

- 30+ Year design life

- 4.4 lbs working load

- -40°F to +392°F working temperature

Installation explained: Are there racking/tracker partner integrations or brand-specific versions available? If yes, list them: The Solar Cable Bridge can be quickly and easily installed by hand, with the strap being bent around the perimeter of the torque tube and secured with the supplied nut and bolt. The small face of the Solar Cable Bridge is then slid under the strap, positioned over the bearing housing and secured in place by tightening the supplied nut. You can then secure cables as normal using Power-Tie or traditional zip ties, through the helpful slots on the Bridge face, providing an additional layer of cable protection at this key pinch point. Gripple Solar Cable Bridge is approved for integration with Array Technologies tracker systems.

Bolt Mount Ratchet Clamp

Application: Wire Management

Material: Engineered polymer made of our industry leading HIRHSUV resin. High Impact modified, High Heat and UV Stabilized PA66.

Install: The bolt mount ratchet clamp has taken our award-winning Ratchet Clamp design and made it more versatile in installation method, cutting down on the size and space needed for installation by removing the metal mounting tab.

Key feature: Basically, you can use any mounting method you choose to mount the new Bolt Mount Ratchet Clamp.

Total MWs installed in U.S. by year-end 2022: 30+ GW

REEL PnP

A hybrid of our product and engineering expertise, the Reel PnP system is the result of customizing each row and reel to the exact specification of the installation. Ultimately increasing productivity and thereby eliminating costly labor time.

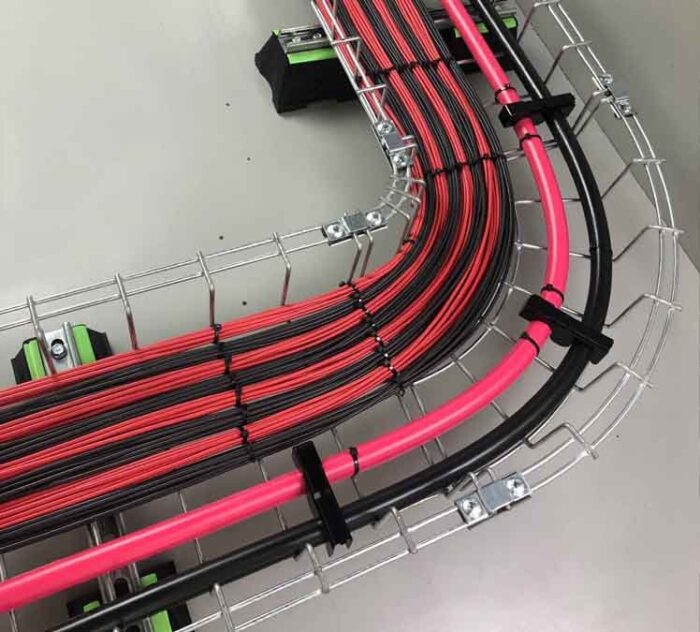

Voltage Lynx Trunk Bus

Next-generation technologies utilized in the manufacturing process enable the Lynx to provide greater efficiencies while reducing labor and material costs. The trunk bus system eliminates multiple traditional components on a utility scale solar installation. These improvements reduce the number of connections, potential variable challenges and the amount of equipment that requires upkeep and repairs throughout the lifespan of the solar installation.

Voltage Reality

State-of-the-art VR/3D rendering files enable engineers and pre-construction teams to accurately address revisions and design options, lessening the number of change orders and resulting in cost savings.

Fixed tilt, solar canopies, dual-axis trackers

TITAN Series - Driven Pile or Dual Screws

Number of pieces: Titan: 1,154 per MW; Titan Duo 1,130 per MW

Certifications: ASCE 7-10 & CPP Wind Tunnel Tested

Installation: A pile driver installs the pile foundations for TITAN racking. APA screw machines are attached to skid steers to drive the ground screws. With the TITAN Duo, 100 percent pre-drilling is offered to ensure any bedrock or hard obstructions do not cause significant delays during installation. The racking attaches to the foundations and can be adjusted in the field to maintain the proper array height and design.

Advantages: The TITAN’s unique asymmetrical design and innovative features allow for flexibility in the field while streamlining the install process. It has the lowest part count per MW and integrated wire management. The patented Gravity Clip reduces module install time by 35 percent. The 3-rail design is an excellent solution for bifacial modules, providing low backside shading. The TITAN has the industry’s strongest C-pile with opportunities for adjustment. The screws are telescoping providing 18” of adjustability for topography.

Ready Rack Pre-Engineered Kit

Number of pieces: varies for each project – avg. 548 pieces for a 12KW project

Installation: The Ready Rack Pre-Engineered Kit is great for smaller projects and comes in two module increments. The kit has multiple foundation types and provides a solution for all subsurface conditions. It comes with everything needed to install the racking and is delivered on a 4’x12’ pallet. Additionally, there is no need to source any pipes or concrete with this product. The layout and dimensions are site specific and can be easily referenced in the provided plans. The helical and ground screw foundations are simply installed by using a skid steer and auger attachment.

Advantages: Designed specifically for smaller residential and commercial solar installations, it comes with all required components and has approved engineering documentation already completed and included; just pick your parameters and go. The design is a simple configuration that allows contractors to install the system fast. A 10 kW system, for example, can be installed in one day. Integrated features allow for onsite adjustment and anchors paired with quick-install bracing make this simple system extremely robust.

A-Frame Tracker Interface

Three pieces: Ground screw or helical, leveling flange, A-Frame.

Design: The helical piles or ground screws are driven with a rotary head. Then the A-Frame is attached to the piles with four bolts. The A-Frame uses a standard I-beam section to the solar tracker system. This allows seamless transition from driven I-beams to the A-Frames, leaving connection hardware the same. The leveling flanges allow for up to 20 in. of height adjustment to keep the A-Frame plum and level. The dual post design allows for ground screws or micro helicals for the foundation and are driven using a rock drill.

Advantages: The A-Frame advantage is its dual post design, allowing developers to substitute the traditional pile-driven foundation for a dual ground screw or dual helical foundation to accommodate rocky or softer subsurface conditions. The adjustability in the A-Frame also aids in dealing with topography and managing in-field adjustments to maintain the design of the array. Helicals are designed for softer soils, while ground screws are best suited for rocky or harder subsurfaces that have cobbles or other obstructions.

apasolar.com | Sales: sales@apasolar.com

Specialty: Residential and C&I <500 kW

SunTurf Ground Mount

Average row construction time: 4LX12 array 20K system installed within 1 day (10am-2pm)

Slope tolerance: Up to 27% slope east-west.

Certifications: UL 2703

Installation: No cutting, welding, or drilling. Adjust height and install posts with set screws. Pipe fittings attach quickly with set screws. Two-piece pipe caps make installation easy. Structural splice with set screws for bonding. Fast rail attachment with T-bolts. The SunTurf Ground Mount System easily integrates Helio Rails with Schedule 40 Steel Pipes. Combine SunTurf with SunModo Ground Screws or Augers and do a complete install of a 15-kW system with only one day on the job site. For a more interactive look at SunModo’s Ground Mount, check out this video.

Advantages: SunModo offers the next generation SunTurf Ground Mount System. The streamlined design combines the simplicity of a pipe-based system with next-level engineering. SurTurf Ground Mount is ideal for solar installers looking for a low cost high performance system that can accommodate a wide variety of soil conditions. No drilling is required to attach the aluminum rails to the horizontal pipe. The innovative swivel pipe cap kit can accommodate terrains up to 27% slope east-west and 120% slope north-south.

Specialty: C&I size projects. The universal design, manufactured from UV rated glass reinforced Nylon 6, enables the installation of all framed modules and stands up especially well in highly corrosive conditions near the ocean.

www.sollega.com | Sales: Info@sollega.com

Specialty: Dual-axis trackers.

M16KD Dual-Axis AgriTracker

Mechatron Solar’s M16KD at World Ag Expo 24; Credit Chris Weber

The M16KD AgriTracker is manufactured in Stockton, California by Mechatron Solar, that manufactures unique, patented dual-axis photovoltaic trackers. With a ground coverage ratio of 28% to 50% (depending on panel type), the M16KD solution requires only 4 acres per MW of array. The gearless, hydraulic design drives more through 360 degrees of Azimuth rotation and 60 degrees of Zenith inclination.

Highly weather-resistant, the M16KD tracker withstands wind gusts of up to 115 mph; a version with heavier purlins is available for wind speeds up to 135 mph. The M16KD also withstands snow loads of nearly 35 psf, although snow loads have been demonstrated to shed readily in Canadian latitudes.

The flagship M18KD tracker supports 90 solar panels. The company’s unusually high-yield trackers have the highest energy density and the lowest ground footprint in the industry. Mechatron solar trackers include gearless azimuth trackers and gearless dual-axis trackers, which are designed to maximize performance with a lower operations and maintenance cost than other commercially available tracking systems. They have been successfully tested under different climate conditions rate structures constitute the best available solution for photovoltaic plant installations.

Mechatron was certified under UL 3703 in 2022 and completed a bankability analysis by Black & Veatch. The flagship tracker also features a new digital guidance system, along with a new optional design with eight columns to accommodate large format modules. The M10KD residential model features a reduced table size to support 49 panels, to accommodate limited space requirements.

MK18D Carport Tracker

The M18KD-20 carport tracker yields 40kW of power, is capable of 360 azimuth rotation and 0-25 degrees of elevation tilt.

Best suited for: Carports where available land space is limited or constrained.

Advantages of design: The M18KD-20 offers dual-land use. The single mast allows deployment with minimum parking area usage and provides uniform shade to vehicles while harvesting the highest possible energy from the space, yielding over 2,200 kWh/kW annually.

Company specialty Infinity Rack produces truly, reliably watertight solar canopy solutions that are simple to install, they look incredible from any angle, and are the most durable solar canopies on the market.

MWs installed in North America: Over 1 MW in these first 2 yrs of distributions.

U.S. manufacturing footprint and capacity: We have USA, Canadian, Mexican, and EU patents in place. We can fulfill orders at MW scale and ship anywhere from North Carolina.

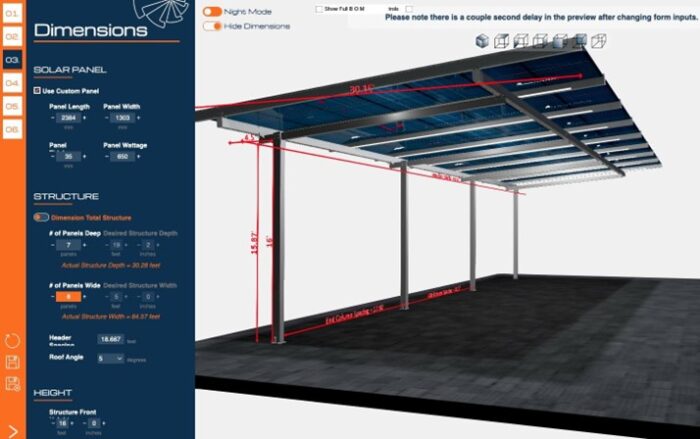

Infinity Rack Cantilever Structures

Infinity Rack now produces fully cantilevered steel structure designs that can cover any size parking area or outdoor space with a reliably watertight solar canopy, offering up to a 30’ low-clearance and a lifetime structural warranty.

Infinity Rack Solar Canopy Kits

Avg. row construction time: Installs in almost the same timeframe as a typical, similarly sized (kWDC) ground-mounted array.

Best suited for: Any watertight shade solution for any environment.

Advantages: A Mechanically Watertight solar canopy with an Integrated PV Wire-Management Solution and an infinite range in design; including structural BIPV (Building Integrated Photovoltaics). 2604 Powder Coating is standard in black, white, or tan. Additional luxury finishing upgrades available.

How does it install? Once the engineered footers (concrete form or helical pilings) are set then the column bases attach using concrete anchors. There are detailed install manuals and videos but the process is very intuitive and mostly goes together with a half inch socket. Infinity Rack also provides our own in-house technician on your jobsite to train your team during their first Infinity Rack installation.

Certifications: NEC Compliant, UL in process

Infinity Rack Framed-in Solutions

Every column, frame beam and header that make up our All-Aluminum Structures, is actually two pieces that have four standard sized M10 T-Bolt rails running their entire length. You can frame lumber directly to the T-Bolt rails on any standard or custom sized structure. For example, the displayed structure is over 51kWDC with five parking spaces and six secure storage units.

Infinity Rack 3D Canopy Configurator

The Infinity Rack 3D Configurator is a free online software that instantly renders solar canopy structures of any size. Accessible from our website, this powerful tool can be used with clients to maximize project input and reduce redesigns. Future capabilities of this online portal will include lead distribution to registered EPCs, plan set generation, and augmented reality image files you can overlay onto any potential site with your phone.

Company specialty: Paired Power offers solar-powered microgrid for EV charging and emergency power.

MWs installed in North America: 1MW

U.S. manufacturing footprint and capacity: U.S.-based BABA (Build America-Buy America) manufacturer in Campbell, California whose products qualify for the 40% federal ITC on all purchases.

PairTree