HelioVolta report: Urgent issues found in majority of solar project inspections

Safety and reliability issues in C&I solar systems continue to rise according to the second annual SolarGrade PV Health Report published by HelioVolta, a provider of independent inspection and technical advisory services. Seventy-two percent (72%) of HelioVolta’s inspections identified safety and reliability issues that required urgent remediation. This is an increase from 62% last year. (See our “Roofs of Hazard” report from last year)

This year’s wakeup call comes in conjunction with a solution: a detailed matrix for calculating risk in the field, built by HelioVolta, available free online for use in the field. More on that later. First, the wake-up call.

The SolarGrade PV Health Report highlights findings from over 100,000 PV system data points that were catalogued in the SolarGrade mobile app during site visits by field engineers on hundreds of projects in the U.S. and Puerto Rico (median project size of 500 kW, 76% on C&I rooftops). This year’s edition incorporates data from construction quality control and commissioning inspections for the first time.

Key findings from the 2024 report:

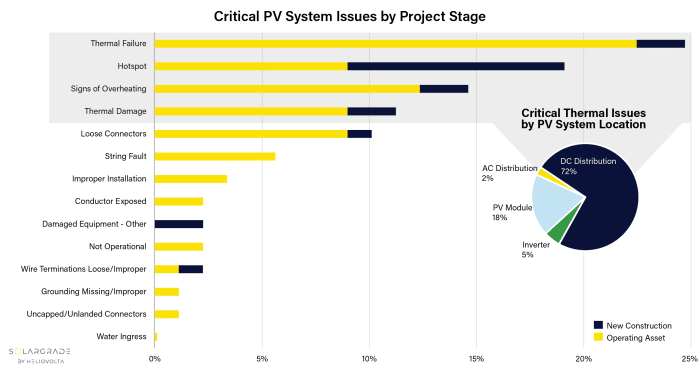

- 11% of inspections found “critical” safety issues requiring total or partial de-energization (up from 9% last year). These require immediate self-isolation and remediation ideally before leaving the site — 80% of these critical issues were found in operating assets.

- 56% of critical risks were located in DC distribution, followed by PV modules at 25% (this category includes factory-made PV connectors), and inverters at 10%.

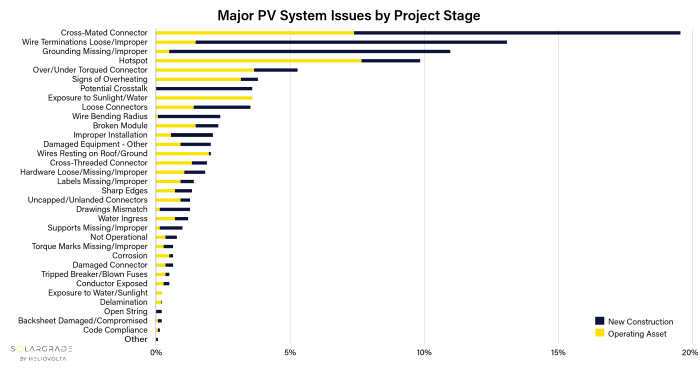

- Here’s a look at all of the critical issues divided by project stage:

- Among “major” issues (the risk categorization below critical), cross-mated connectors are the most common at nearly 20%. In the report, HelioVolta notes cross-mated connectors are only classified as “major” when they are systemic or present in >90% of the system.

- Across all risk categories, wiring and connectors generate more problems than any other PV system component — 80% of inspections found wire-related issues; 83% of inspections found connector-related issues.

Important note: HelioVolta says it had more engagements on fleets with serious problems in 2024 vs. 2023. Roughly 40% of the health audits since the 2023 report took place at randomly selected projects in fleets with prior failures. Third-party construction QA/QC was not conducted at most of these sites, and

The overarching message here is the vast majority of issues identified in operational systems could be avoided with that QA/QC and thorough O&M protocols.

“We share field intelligence from SolarGrade to help developers, EPCs, O&M providers, and asset owners optimize processes and prevent costly failures, but our ultimate goal is to empower them to collect and act on their own site data.” said James Nagel, co-founder and COO of HelioVolta. “As we face the growing urgency of the climate crisis, it’s essential to build clean energy assets that both perform and endure.”

Addressing the issues

Download the full report here. If you’re reading this on Aug. 20 before 3 pm ET, you can also register for Dispatches from the Energy Transition: The Impact of Field Intelligence webinar, where the HelioVolta team will discuss their findings with Mayfield Renewables.

While these statistics may be alarming, the report’s findings show that asset owners and managers can readily address PV safety and reliability challenges. A two-part solution is required:

- first, installers and field technicians must have the right tools to find and monitor safety and reliability issues, and then

- they must objectively assess the risk of each issue.

Timely, accurate information from the field can lead directly to appropriate remediation plans.

“The SolarGrade report is a wake-up call for the industry, but the data shows that the majority of safety issues we encounter are preventable with the right tools, practices, and a strong emphasis on education and training,” says Ryan Mayfield, founder and SME of Mayfield Renewables. “Investing in comprehensive training programs is essential to equip professionals with the knowledge and skills needed to ensure safety and excellence in solar installations.”

Risk matrix for all

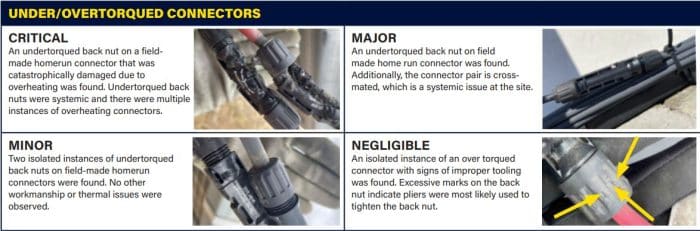

The solar industry does need to standardize on risk definitions. When writing that Roofs of Hazard article last year, it was difficult to compare data and takeaways from the 2023 SolarGrade report to a similar 2023 report from Clean Energy Associates. Here’s an example from the 2024 SolarGrade report, illustrating how the same basic issue can appear at each level of severity.:

The implications of not having standard definitions:

- When low risks are overstated, time and money is wasted on unnecessarily urgent corrective actions that can wait to be addressed.

- When high risks are understated, important corrective actions are not taken and safety incidents are more likely.

- When severity levels are disputed, delays in system construction and commissioning, stalled contractor payments, canceled project transactions, and even costly legal actions can occur.

Building on the foundation of the inaugural report, this year’s report introduces a detailed matrix for calculating risk in the field used by HelioVolta’s field engineers. A mobile-ready matrix is also available free online for use in the field, further enhancing the tools available to solar professionals.

“Clear, standardized communication around risk is essential. When technicians, operators, and managers define terms like ‘minor’ and ‘major’ inconsistently, genuine risks are overlooked until they progress into damaging safety events,” commented David Penalva, co-founder and CEO of HelioVolta. “The SolarGrade platform helps ensure that problems are accurately identified and dealt with before they lead to significant failures that are costly and dangerous.”

Comments are closed here.