Rooftop Solar BOS Buyer’s Guide 2025

A solar PV rooftop system is only as good as the mounts, rails, clips, conduit and connection points — the balance of systems (BOS) — that keep everything structurally in place and electrically humming. Each year for the Rooftop Solar BOS Buyer’s Guide, we reach out to every manufacturer in this space to update their product portfolio and to get a peek at what’s new in the coming year.

A hot topic this year is domestic content because structural systems weigh heavily in the Safe Harbor Tables for calculating a project’s domestic content percentage to earn the DC tax credit adder. We asked each manufacturer which products qualify for domestic content.

Here’s an overview of what’s new in 2025 for prominent rooftop mounting, racking, and wire management manufacturers, followed by the complete product portfolio showcase. The Product section is divided into

- Mounts & Rail Systems

- C&I Rooftop Specialists

- Wire Management & J-Boxes

What’s new on the rooftop in 2025?

At the beginning of 2025, SunModo successfully completed the UL 3741 listing process for both NanoRack and SMR Roof Mount systems. SunModo is continuing to be proactive with its supply chain to meet the continuously changing demands of the industry and expects to have domestic content available for their full line of products in Q1.

This year, QuickBOLT will showcase its stone-coated steel training at NABCEP, along with new digital training initiatives. They also introduced the QuickPATCH, a metal patch with an adhesive backing designed to seal roof holes caused by installations, aging, or weather, providing durable, leak-proof protection. In C&I, the QB RibRider from QuickBOLT is now available for trapezoidal or ribbed metal roofs, featuring an adjustable base, rotating L-bracket for dual rail-mounting, and a Butyl Bottom for superior weatherproofing.

Roof Tech is debuting the new RT-PLUS — an extruded aluminum PV rail mounting system featuring their AlphaSeal self-flashing system. This new mounting system can be fastened directly to rafters or decks (OSB and plywood only), and is available in a sleek MIL finish or elegant black:

In 2025, EcoFasten has added Domestic Content components to its line of products while also pushing our systems through UL 3741 conformance.

Pegasus Solar recently introduced three major hardware products: InstaFlash2 (comp roof mount for rafter or deck attach), InstaTilt (for flat roofs), and BondBox (simplify grounding). Pegasus also integrated its Pegasus Design Tool with Aurora and is introducing Pegasus Permit Services, which provides everything needed to submit to local AHJ in 24 hours. The company has expanded distribution to Hawaii, and the SkipRail system and InstaFlash2 have been certified for UL3741 and by Florida for High-Velocity Hurricane Zones.

A newcomer gaining traction headed into 2025 is Sunstack. The team is adding new options for their Integrity line this year — a flush mounted tilt leg for 5,10 &15 degrees. A hidden end clamp and additional wire management solutions will also be added to the integrity rail offering. Watch for a rail free product later in the year.

SnapNrack launched two new roof attachment families with its SpeedSeal+ Technology – the rail-based UltraFoot for Ultra Rail and the new rail-less AlphaTrack and DeltaTrack for TopSpeed Universal (formerly known as RL-U). The new attachments feature a pre-installed butyl pad for peel & stick installation.

S-5! is experiencing increased demand for its solar attachment solutions that allow easy attachment of rooftop accessories to metal roofs while maintaining roof integrity. In 2024, S-5! prioritized certifications through third-party testing agencies, and this year, the company will continue to innovate with new attachment and mounting systems, as well as related accessories. Learn more about metal roof attachment and cost savings via domestic content in this Solar Builder Webinar:

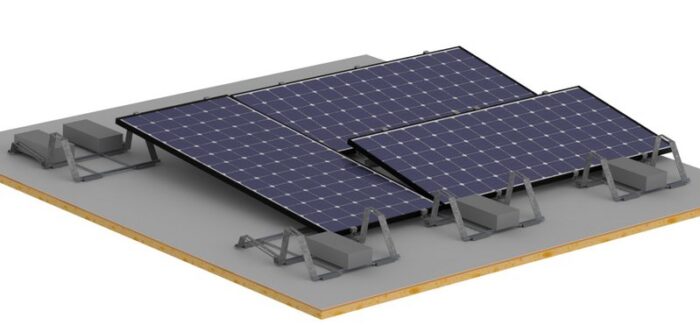

Sollega continues to lead with its lightweight, non-corrosive FR510 system. To support growing demand, they are ramping up production and anticipate more demand because the product is 100% made in the U.S. Sollega’s new Online Design Tool launches in Q1 2025 to generate PV layouts using satellite imagery, and create permit-ready reports.

In light of UL 3741, Heyco has seen a slight shift away from traditional wire management clips (SunRunner clips) since they are constructed from stainless steel material. Heyco has recently released a number of UV nylon parts that attach either to the solar panels themselves or to various racking systems in the market that may be of interest as UL 3741 continues to develop.

The ballasted flat roof racking system from the aptly named SunBallast is officially UL2703-listed by CSA Group. The company now features an extensive list of approved modules.

Unirac is hyped about the GridFlex 10 (GFX10) for flat-roof solar installations in need of reduced ballast and intuitive wire management. Unirac’s UL 3741 catalog continues to grow too, offering more solutions for integrated safety and efficiency.

AceClamp’s Color Snap Universal Screw Down Bracket allows its Color Snap rail to be installed on virtually any roof type. Designed for quick and easy installation, it provides a versatile and dependable snow retention solution for various roofing surfaces. No set screws.

AEROCOMPACT evolved the COMPACTFLAT S for faster assembly with an integrated ballast-platform. Learn more in this Product of the Week.

In 2025, K2 Systems is shifting focus toward the commercial sector, emphasizing the South Face system and the Simple Tilt System with K2 Armor and Big Foot, which are suitable for both flat roof residential and commercial installations.

PanelClaw expanded into Europe in 2024 by combining forces with another Enstall group company, formerly known as CPX and now PanelClaw Europe. The clawFRplus mounting system was introduced mid-year and is now in high volume production. A higher capacity wire management accessory for the clawFR platform, Homerun Clip & Cover XL, was rolled out in Q4.

SolaDeck expanded its all-metallic product line in 2025 to meet the demands of all types of installs, adding a smaller, lighter 0599 flashed junction box and the 0399 universal rail mount box to the original 0799 line to fulfill all needs.

Mounts & Rail Systems

Training program: QuickBOLT has four NABCEP certified courses totaling 5.5 hours of available credits. Visit this webpage for more details. Otherwise, QuickBOLT provides install training for new customers to ensure they know how to use our mounts properly, and will enjoy the benefits as intended.

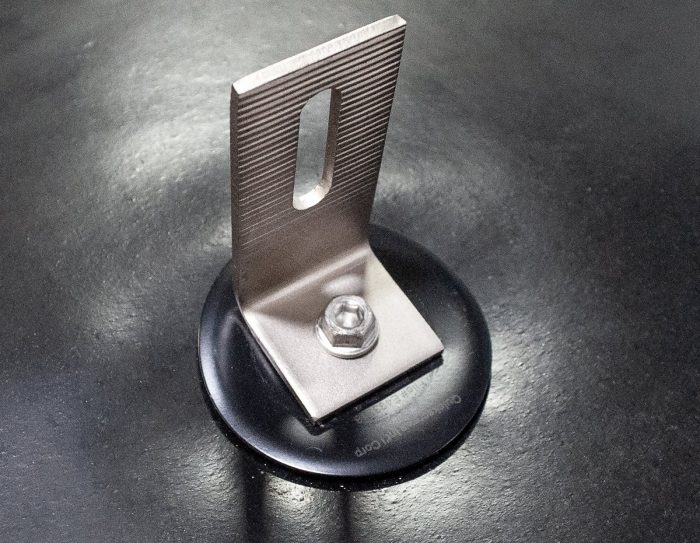

Split Top Butyl Bottom Deck Mount

Components included: 1 butyl-backed Split-Top T-Foot, 4 - 5/16" x 2 1/2" stainless steel hex lag Screws with Sealing Washers. PN #16334

Tools needed: ½” Nut Setter. Recommended PN# 17655.

Advantages: The Split-Top Butyl Deck Mount is designed for fast and leak-proof installations on Asphalt, EPDM, and TPO roofs. This mount offers versatility, allowing you to mount anywhere on the roof deck. The T-Foot features a split top for use with open channel rail utilizing Saddle Mounts or for dropping in rail. The butyl base ensures superior water protection and quick placement, while the stainless-steel T-foot provides easy leveling and rail adjustment. Each mount comes with 4 screws with pre-assembled sealing washers for a secure fit. The pullout ratings keep your array secure: 1310 lbs deck-mounted or 3,228 lbs rafter-mounted.

How does it install: Install anywhere on the roof. No need to locate rafters. Place T-Foot on the roof and press firmly into place. Insert all 4 hex lags and drive the screws until the umbrella washers are compressed. (To Drive Screws and Set Umbrella Washers Properly Torque PSI should not Exceed 57 lbs/Inch). The Split-Top Butyl Deck Mount works on Asphalt, TPO and EPDM roofs.

Certifications: UL Recognized Components, Miami-Dade Approved, PE Tested

QB2 with Microflashing

Components Included: 1 3” Microflashing®, 1 QB2 Bolt, 1 L-Foot. PN #17662, 17862

Tools Needed: 1/2" Nut Setter or 6MM Hex Driver. Recommended PN# 17655. Sealant (optional)

Certifications: UL Recognized Components, Miami-Dade and Florida Approved, PE Tested

How does it install: Place the Microflashing over the shingle. Drive the patented Dual Drive Shoulder Screw through the rafter until the L-Foot is fully secured. You will know it is secure when you see the Microflashing mechanically compression-sealed to the roof. We call this technology: BoltSeal. Intertek Lab ASTM testing confirms that QB2 can be installed without sealant. QB2 works on Asphalt Shingle, TPO, and EPDM roofs.

Advantages: QB2 only has 3 components and can be installed in less than 30 seconds. Unlike bulky sheets of flashing, Microflashing is installed without lifting shingles or removing nails. QuickBOLT is the only Top Mount in the industry that uses BoltSeal technology, which allows QB2 to be mounted on a variety of asphalt shingle, EPDM, and TPO roofs that other flashing cannot. During seasonal weather changes that may cause expansion and contraction on the rooftop, the Stainless-Steel L-Feet have the flection capacity to move with the solar array.

The Throne

Components included: L-Feet, Set Screws, and Grip Plate

Tools needed: Torque Wrench or Hex Key (for M10x25mm Set Screws)

Certifications: UL Recognized Components, PE Tested

How does it install: Place The Throne over metal roof seam and tighten Set Screws.

Advantages: The Throne speeds up install time significantly with pre-assembled parts, ready to place and tighten. Simply your install and reduce unnecessary steps on the roof. The mount includes a Grip Plate with cross-knurling that provides extra grip, enhances pull-out resistance, and protects the roof.

Height Adjustable All Tile Hook - for Side Mount Rails

Components included: 1 hook, 2 screws. PN #17587, 17589, 17593

Tools needed: Recommended: Drill bit, #15433 or 15437 Hex Driver, Sealant compatible with roofing materials

How does it install: Remove the tiles from the install area. Locate and mark the rafters. Place the mount and predrill the holes. Fill the predrilled holes with sealant. Drive the mounting screws to secure the mount and place the tiles back over the mount.

Advantages: QuickBOLT’s versatile All Tile Roof Mounts work on Flat or Curved tile roofs. The wide range of adjustability and leverage points ensure that you can use these mounts with any tile roofing style and work around inconveniently located rafters.

Conduit Puck Kit

Components included: 1 EPDM Cylinder, 1 Mounting Screw, 1 - 3/4" Clip + Screw. PN# 16323, 16324

Tools needed: Recommended: Impact Driver or Drill and 7/16th”Hex Driver

Application: (in case it has a specific application. Rail or rail-less? Residential or C&I? Certain C&I roof types?)

Material: 2-1/4" EPDM Conduit Mount. Steel Conduit Clip with Zinc Plating

Key feature: The Conduit Puck™ Kit’s low-profile design is ideal for homeowners, providing a sleek look on the roof. Speedy install in 5 seconds or less, no predrilling or sealant required. Skip locating the rafter and attach anywhere on the roof deck. Works on a variety of roof types: Asphalt Shingle, TPO, or EPDM. Uses torque-driven compression to create a watertight seal. Protects the integrity of the roof – no lifting shingles or removing nails and staples.

How does it install? Open the Conduit Clip slightly in order to place screw through base hole. Thread the Mounting Screw with Clip into Puck hole, just enough so it doesn’t fall out. Next, orient Clip to conduit direction. Use 7/16th hex driver to fasten, then thread the bolt through clip’s top hole.

All Stone Coated Steel Hook

Components included: 1 hook, 2 screws. PN# 17640

Tools needed: Recommended: Drill bit, #15433 or 15437 Hex Driver, Sealant compatible with roofing materials

Certifications: UL Recognized Components, PE Tested

Installation: Remove the metal roof tile. Locate and mark the rafters. Place the mount and predrill the holes. Fill the predrilled holes with sealant. Place mount over lower roof tile, drive mounting screws to secure the mount and place roofing panels back over the mount.

Advantages: The wide base allows for more range when bolting to the roof rafter and the 3 points of attachment for the arm allows you to move the arm according to the location of the barrel on curved profile models. Works on direct to deck and batten systems.

QB2 with Microflashing (C&I)

Components Included: 1 3” Microflashing®, 1 QB2 Bolt, 1 L-Foot. PN #17662, 17862

Tools Needed: 1/2" Nut Setter or 6MM Hex Driver. Recommended PN# 17655. Sealant (optional)

Certifications: UL Recognized Components, Miami-Dade and Florida Approved, PE Tested

How does it install: Place the Microflashing. Drive the patented Dual Drive Shoulder Screw through the rafter until the L-Foot is fully secured. You will know it is secure when you see the Microflashing mechanically compression-sealed to the roof. Intertek Lab ASTM testing confirms that QB2 can be installed without sealant.

Advantages: QB2 works on more than just Asphalt Shingle. Install QB2 directly to TPO and EPDM roofs using the same simple steps that save you time and money on your installations. QuickBOLT’s patented BoltSeal technology is so powerful that you don’t need to rely on chemical sealant to keep water out, saving you an extra step on the roof.

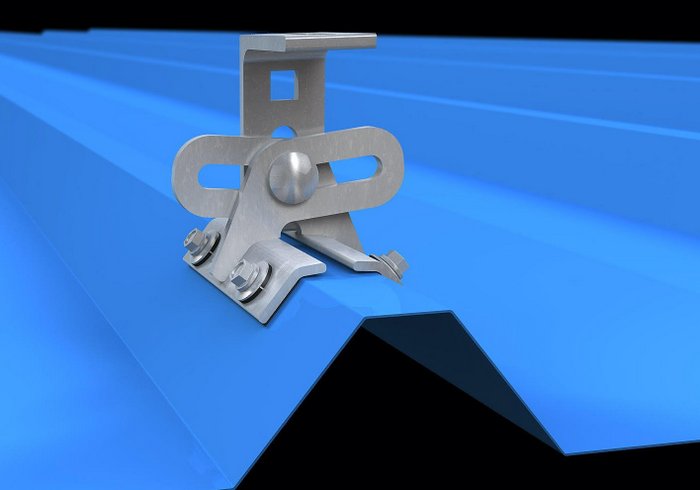

QB RibRider

Components included: Stainless Steel Roof bracket with 4 - 14 x 1 ¼" Hex Washer Self-Drilling Screws. Mount is equipped with two factory-applied butyl pads on both bases and a rotating L-bracket for mounting at 90 or 180 degrees. PN #17766

Tools needed: 3/8” socket or nut setter (for 1/4 x 3/4” Screw) and 1/2” socket or wrench (for M8 Flange Nut).

Advantages: The QB RibRider is ideal for installers and contractors working on exposed fastener, trapezoidal, or ribbed metal roofs. It provides an adjustable base that fits various rib widths, heights, and angles, making it compatible with multiple roof profiles. It includes 75mm butyl pads for strong weatherproofing and a rotating L-bracket for mounting at 90 or 180 degrees. This mount is easy to place and secure, providing a solid attachment to the roof.

How does it install: The QB RibRider’s width is adjustable. To adjust mount to rib profile, loosen center nut to adjust width of the arms. For bottom rail mounting, rotate the L-Foot flat side up. By default, the L-Foot is flat side down for side rail mounting. Once center nut is loosened, remove protective paper from Butyl. Next, place the mounting arms Butyl side down on rib in marked location. Fasten mount to rib using included screws, then tighten center nut and check angle of L-Foot. Torque values should not exceed 20 PSI. Screws will drive in with little or no pressure required. Too much pressure could cause spinout. Do not predrill.

Certifications: UL Recognized Components, PE Tested

Distributors list: Wesco, CED Greentech, CES, Codale Electric Supply, Cooper Electric, Beacon Solar Products, Griprac, Independent Electric Supply, Onesource, Ontility, Tamarack Solar Products, The Solar Raq, Boral Roofing, Chiko Solar, Platt Electric Supply, Krannich Solar, Soligent and more…

Website | rgentry@quickscrews.com

Roof Tech Inc. has been engineering solar mounting solutions since 1994 with over one million rooftop installations all over Japan and North America. They offer a 25-year warranty on every product from the installation date with its AlphaSeal Technology.

- Describe your U.S. manufacturing: Third-party manufacturing

- What products qualify for domestic content: RT Rail system

- What notable AVLs are you listed on? SunnovaSolar Plus

RT-PLUS

Components included: base, screw, flashing

Tools needed: Hex driver

Advantages:

- AlphaSeal® self-flashing system

- Operating temperature from -40F to 248F

- No Caulking or Pre-Drilling Required

- Universal Attachment to Any Slope

- Metal, EPDM, TPO, SBS, & Asphalt compatible

- 5 Round mounting holes for deck attachment (OSB or Plywood)

- 2 Square holes for rafter attachment

- Available in black and mill finishes

- Rail mounting slot for 3/8” and 5/16” bolts

How does it install: The RT-PLUS is a combination of our best seller, the RT-MINI II base, PLUS an integrated L-foot. Designed for ultimate versatility and durability, our new mounting system can be fastened directly to rafters or decks (OSB and plywood only), ensuring a secure and efficient installation.

Certifications: UL2703A pending

RT-APEX (rail-less)

Number of pieces: Three to eleven based on configuration.

Tools needed: Six

Certifications: UL 2703,441, ICC ESR 3575, TAS 100, ASTM 2140,1970, HVHZ Certified

Installation: The RT-APEX fastens to rafters or direct to the roof deck (7/16 OSB minimum) or a combination of both. Chalk lines are needed to plot the location of the bases. When fastened to a rafter, it uses five mm diameter mounting screws, eliminating the need for a pilot hole and caulking. The RT-APEX features slide-in mounting and one-step leveling to adjust and level the panels. The universal clamping feature helps to fit module thicknesses ranging from 30 to 46mm. This advanced rail-less racking system adjusts to fit over forty different PV module manufacturers' solar panels. Roof Tech's solar mounts are self-sealing with engineered integrated AlphaSeal, creating a waterproof mounting system.

Advantages: The rail-less RT-APEX is faster to install without the use of rails. It also provides less weight on your residential roof to uphold the structure's integrity. Without the use of rails, there is more room for flexibility, and design helps improve the ascetics of the roof. Rail-less, deck-attached installs take half the time of traditional rafter-mounted rails with metal flashing than with the RT-APEX with flexible flashing. Design your build with the RT-APEX span calculator for free by registering here.

RT-MINI II

Number of pieces: Two

Tools needed: Five

Certifications: UL 2703,441, ICC ESR 3575, TAS 100, ASTM 2140,1970, HVHZ Certified

Installation: The RT-MINI II has more options for installing rafters and handling thicker insulation on low-slope roofs. It comes with an option of two 90 mm screws to offset rafter mounting, allowing for more attachment options on any style of roof and pitch. Design your build with the newly featured RT-MINI II span calculator.

Advantages: The RT-MINI II is a universal attachment for railed systems designed to be agnostic to any roof type and roof pitch engineered to withstand wind speeds up to 180 mph and ground snow up to 90 psf. The main difference between RT-MINI II and conventional flashing is the faster installation time because RT-MINI II is fastened with wood screws, eliminating the need for pilot holes and caulking. As a result, there is no damage to the seal on asphalt shingles, so the roof warranty remains intact.

RT-CONDUIT MOUNT

Residential or C&I? Residential

Components included: RT-CONDUIT MOUNT with AlphaSeal® System (RT-Butyl + RT Screw)

Tools needed: 5/16” or 8mm hex socket.

Certifications: International Code Council

How does it install: RT-CONDUIT MOUNT featuring a double flexible flashing system. By pressing the top with a thumb, the installer feels the location for the mounting screws. Once the conduit position is laid out by either a chalk line or from the conduit secured between two points, adding the RT-CM’s along the way is an easier process. Both direct to deck (OSB or Plywood) or rafter attachment (with the optional 5x90mm RT Screw).

Advantages: It features AlphaSeal, Roof Tech’s flashing system certified by the ICC (International Code Council). Designed with a height (top of roof to bottom of conduit) that avoids derating the ampacity of the conduit (NEC), it allows for either a cowboy clamp (close conduit pipe clamp) or half-moon (conduit strap) conduit clamps ranging from ½” to 1” dia. conduit. The clamps are not included, since it is common item carried by all contractors used on other parts of the array assembly. It is packaged 20ea per box (RT 5x60 mm screws included). Each box measures 3 x 4 x 12 inches and weighs 3.7 Lbs. It also has a sleek, black design that leaves a more aesthetically pleasing end result.

Distributor’s list | Website | sales@roof-tech.us |

Domestic content? SunModo offers racking solutions (both rails and fasteners) that meet the domestic content requirements of the IRA.

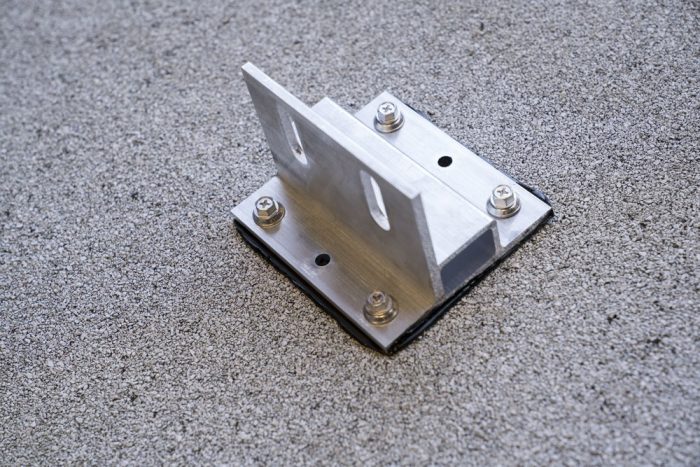

MRB

Components included: MRB Mount, 4 Self-drilling Screws

Tools needed: Impact Driver, 13mm socket

Certifications: High-Velocity Hurricane Zone Approved – Passed TAS 100 (a) Wind Driven Rain Test

How does it install: The MRB Mount installs into 26-gauge sheet metal, 1/2 plywood or 7/16 OSB roof decking material. Remove the protective linear covering the EPDM gasket adhesive. Secure to 26-gauge minimum thickness sheet metal using four Self-drilling Screws. Adjust the L-Foot with its M8 Bolt onto the top of the clamp; use a 13mm (1/2”) hex socket and torque to 13Nm (10 ft-lbs).

Advantages: MRB is a versatile metal roof attachment. Specially designed to work for various metal roof profiles, the MRB adjusts to attach to almost any metal roof. Pre-applied adhesive makes attachment easy. Adjustable “wings” make MRB the single SKU solution for any shape metal roof.

- Most versatile metal roof attachment on the market.

- Fully pre-assembled with adhesive gasket.

- Simple, fast anchoring to sheet metal or wood decking.

NanoBit

Components included: NanoBit, 1 lag bolt

Tools needed: Impact Driver, 13mm socket

Certifications: High-Velocity Hurricane Zone Approved – Passed TAS 100 (a) Wind Driven Rain Test; Florida Product Approval (FPA)

How does it install: Apply a circular bead of sealant around the bottom of the NanoBit. Locate the center of the truss, rafter, or purlin in the desired roof location and drill a pilot hole. Clean sawdust, and fill hole with sealant. Use a 13mm (1/2”) hex socket to install the Lag Screw.

Advantages: SunModo is proud to introduce NanoBit, Solar’s Fastest Attachment for Metal Roof. Specially engineered for easy installation, NanoBit is the fastest installing metal roof mount in the industry.

- One of the fastest solar attachments.

- Versatile mount works for both shingle and metal roofs.

- Engineered for easy, fast installation on metal roofs.

SMR System

How does it install: One tool assembly and Pop-On technology allow fast and worry-free installation. Fast and easy Pop-On L-Foot Adaptor speeds installation and eliminates old-fashioned T-Bolts. Rail pops into Adaptor quickly and securely. Fully structural bonding splice with fast and easy single bolt installation. The Bonding Pop-On Universal Mid Clamps accommodate PV module frame heights ranging from 30mm to 50mm. Clamp pops on to rail easily and stays upright on rail for easy location adjustment. The Pop-On Universal End Clamps provide fast and easy install with a single SKU for any module thickness. The wire management clip is specially designed for a fast and secure solution for wire management. Pair SMR with one of our industry leading mounting options and save money and time on your residential solar installations. For a more interactive look at SunModo’s SMR system, check out this video.

Advantages: SunModo introduces the SMR Pitched Roof System, the best value pitched roof mounting system on the market. The SMR System represents a huge leap in racking technology. Optimized design makes the SMR Rails not only the lightest but also the strongest rails on the market. With fast and easy Pop-On Clamps and L-Foot adaptors, professional installers can mount, adjust, and secure PV panels with a single tool. Whether rafter or deck, portrait or landscape, the SMR System is the ideal solution for your solar installation. Save money on materials and installation time.

NanoMount

Tools needed: Impact Driver, 13mm socket

Certifications: High-Velocity Hurricane Zone Approved – Passed TAS 100 (a) Wind Driven Rain Test; Florida Product Approval (FPA)

How does it install: SunModo recommends putting a bead of sealant on the bottom of the mount as an extra precaution – but the high performance gasket means NanoMount is not reliant solely upon user-applied sealant for protection. Both rafter and deck attachments are available so NanoMount has the flexibility to cover a wide range of scenarios and preferences. For rafter application, locate the center of the rafter in the desired roof location and drill a 6mm pilot hole. Fill the pilot hole with sealant and use a 13mm hex socket to install the Lag Screw with Sealing Washer. For decking application, locate the desired roof location and install the 4X Self-Tapping Screws with Sealing Washers. Complete the solar panel installation using SunModo’s SMR rail system.

Advantages: Damaging roof shingles used to be one of a solar installers’ worst challenges. SunModo’s newest patented NanoMount eliminates the need to lift shingles and and dramatically reduces the installation time. The NanoMount has an Integrated Ultra Soft Weather Sealing gasket that covers the entire bottom of the mount and is recessed to ensure proper compression. The Ultra Soft material conforms to uneven roof surfaces. There are no pre-punched holes, so the giant gasket seals around the screws to to achieve superior leak protection on roof surfaces. Pre-assembled sealing washers come with either lag bolt or decking screws to prevent water penetration from above. NanoMount has the flexibility to cover a wide range of scenarios and preferences with its verstile base that can be used for either rafter or deck mounting.

SunTurf Roof Mount

Certifications: UL2703

How does it install: SunTurf easily achieves 7′ leading edge height with low cost and provides convenient access to roof surfaces for maintenance and repair. No cutting, welding, or drilling. Adjust height and install posts with set screws. Pipe fittings attach quickly with set screws. Two-piece pipe caps make installation easy. Structural Splice with set screws for bonding. Fast rail attachmetn with T-bolts.

Advantages: The SunTurf flat roof system is perfect to elevate above obstructions such as HVAC, Pipes and Vents. The streamlined design combines the simplicity of a pipe-based system with next-level engineering. No drilling is required to attach the aluminum rails to the horizontal pipe. The system can easily achieve cost effective leading edge height of 7′ or more. By spanning over roof obstructions, the system takes full advantage of the available roof surface thereby maximizing the PV system size and increasing your ROI. The system aso provides convenient access to roof surfaces for maintenance and repair.

TopTile Mount

Components: 6"X4.5" Aluminum Flashing with EPDM Boot, Deck Stanchion and 3 wood screws

Tools needed: 28mm hex socket

Certifications: High-Velocity Hurricane Zone Approved – Passed TAS 100 (a) Wind Driven Rain Test; Florida Product Approval (FPA)

Advantages:

- Cut your tile roof mount installation time in half.

- Adhesive moldable flashing for ease of application.

- Deck mount - No need to find rafters.

- No more lifting roof tiles, or broken tiles.

How does it install: Our patented TopTile eliminates the need to deconstruct the tile roof and significantly reduces time and minimizes tile breakage during installation. The mount works with both flat and curved tile profiles. The TopTile Mount can used to mount directly into roof decking without removing tiles. Locate the desired location of the TopTile stanchion. Using a 2” tile hole saw, drill a hole into the tile. 28mm hex socket is used to install the TopTile stanchion into the deck of the roof. Spray the insulating foam sealant onto the roof deck through the three holes of the stanchion after installing the three wood screws. Remove the protective linear covering the butyl tape. Install Flashing over Stanchion and onto the tile. Attach the L-Foot to the stanchion. Complete the solar panel installation using SunModo’s SMR rail system.

Standing Seam Clamp

Number of pieces: 1 piece (pre-assembled)

Tools needed: 13mm socket

Advantages:

- One product does everything you need on standing seam roofs.

- Attach SunModo's SMR Mid and End Clamps directly to the Standing Seam Clamp and you have a full racking system with no need for rail.

- Attach an L-Foot and use with any compatible rail-based system.

- One tool assembly with all SunModo roof mount products.

How does it install: Solar PV installations on standing seam roofs just got easier with SunModo’s Standing Seam Clamp. No rail needed. SMR Mid and End Clamps attach directly to the Standing Seam Clamp. Save the cost and time of using rail. Simply attach an L-Foot and the same Standing Seam Clamp can be used with a rail-based system.

For more on butyl rubber in general, and what’s special about Roof Tech’s patented AlphaSeal system, check out this article.

EcoFasten, an Enstall Company, has established a reputation for being one of the industry’s leading innovators by providing expert solutions for mounting solar PV on any roof. EcoFasten’s broad portfolio of solar rooftop mounting systems and attachments stems from the direct needs of solar PV installers. EcoFasten takes pride in providing the right solution for every application.

Training program: Elevate E-Learning is EcoFasten’s training program. Certification is awarded by roof type: Composition Shingle, Metal, Tile, or Low-Slope. You can also choose to enroll in one of our NABCEP-Accredited recertification courses.

What products qualify for domestic content: RockIt System, RockIt Smart Slide, ClickFit System , ClickFit Smart Foot, ClickFit Rail, GF-1 Flashing, Skirt

RockIt

Number of pieces: 4

Tools needed: One tool (1/2” deep well socket)

Certifications: UL 2703 and UL 3741.

Domestic content: US Components are also now available.

Installation: Installing the rail-less RockIt System on composition shingle roofing is not only one of the most economical solutions on the market, it’s also one of the fastest and easiest to install, thanks to the use of the watertight EcoFasten flashing that utilizes a single fastener. Once the flashing with RockIt Slides is installed and leveled on the eave edge, move on to installing the first row of RockIt Mounts, Array Skirts, and Couplings. All that’s left is to install the PV modules and continue the installation of upslope mounts and couplings. Level the remainder of the system as you go, or after installation of the PV array is complete.

Advantages: The RockIt System is the industry’s premier rail-less PV racking system available in configurations for composition shingle, tile, and metal roof types. Designed in conjunction with the needs of installers, RockIt quickly and easily installs with a single tool and features EcoFasten’s patented, watertight technology. With a convenient, easy-to-position alignment slide and a top-down leveling system, RockIt is logistically intelligent, with no need to ship or transport long rails. RockIt System provides a streamlined installation, fully integrated bonding, and North-South adjustability. Components are available in a black finish that complements both commercial and residential applications. RockIt conforms to UL 2703.

ClickFit

Number of pieces: 8 with Mid Clamps & End Clamps

Tools needed: One tool (1/2” deep well socket)

Certifications: UL 2703 and UL 3741.

Domestic content: US Components are also now available.

How does it install:

ClickFit on Tile: ClickFit is one of the fastest installing rail-based racking systems in the industry, thanks to the Click-in Rail assembly. ClickFit gives installers the versatility in attachment options they want and is the most cost-effective when installed on tile roofing.

To begin, install the ClickFit Tile Hook and replace the tile that was moved and/or removed, or install the Tile Hook Flashing. Install ClickFit Tile Hook Sub-Flashing next, providing an additional layer of watertight protection.

Place the rail in the Clickers and roll the rail into each Clicker – an audible “click” should be heard. Level if necessary, then install the ClickFit End Clamp on each rail (on whichever end you started with), place the PV module, align, and tighten.

Advantages: ClickFit conforms to UL 2703, features fully integrated bonding, and is one of the fastest installing rail-based systems in the industry. Thanks to its Click-In Rail assembly, the rails can be connected to any of EcoFasten’s composition shingle, tile, and metal roof mounts in seconds, without the need for fasteners or tools. The Mid Clamps and End Clamps are compatible with PV module thickness between 30-55mm.

The ClickFit system is fabricated from robust materials, such as aluminum and coated steel, to ensure corrosion-resistance and overall product longevity. ClickFit has been tested in extreme weather conditions including wind, fire, and snow.

ClickFit Smart Foot

Components included: ClickFit Smart Foot with Clicker

Tools needed: Caulking gun, roofing mastic applicator

Advantages: Created for use with our rail-based ClickFit System, the mount easily attaches to composition shingle roofs. Fabricated from cast aluminum, the ClickFit Smart Foot features our proprietary UltraGrip Technology™. A layer of foam cushioning helps to embed the waterproofing sealant deep into the granules of the shingle and flexibly conforms over the steps commonly found on architectural-style shingles. Simply peel the backing off the release liner from the underside of the UltraGrip pad and place the mount on the shingles.

How does it install: Simply peel the backing off the release liner from the underside of the UltraGrip pad and place the mount on the shingles.

Certifications: UL 2703, UL 2703A

Domestic content? Yes!

ECO-65 (C&I)

Number of pieces: 4

Tools needed: Two Tools (Phillips Head and ½” socket)

How does it install: Once the mounting location has been determined and the roofing and insulation have been cut to accommodate the base plate, install the flashing over the two threaded studs on the base plate, followed by installing the EPDM Sealing Washers over both threaded studs. Place the F-202 Compression Bracket over the threaded studs and place a single bonded washer over each stud with the rubber side facing the roof. Thread it down the stud to the compression bracket before adding the hex nut. Install and tighten down the hex nuts to each threaded stud. Next, attach the mounting bracket or post of your choice to the F-202 using the included all-thread, and finally, waterproof the EFL-BLK-1014 following the techniques specific to the roof membrane.

Advantages: The ECO-65 is a specialty direct-to-deck attachment for low-slope roofing. The roof attachment is engineered specifically for use on new or existing (retrofit) low-slope roofs constructed of rolled asphalt or membrane (TPO, EPDM, PVC). ECO-65 is used by countless manufacturers of ballasted solar racking systems to augment their products for weight reduction and seismic attachment. The ECO-65 base plate is designed to be attached specifically to wood blocking or wood decking, and the mount itself features two studs for attachment, which allows the use of larger compression brackets when needed. ECO-65 is a watertight solution compatible with any racking system.

RibFit

Number of pieces: 4

Tools needed: Two Tools (¼” hex socket, ½” socket)

Certifications: Conforms to UL 2703

How does it install: Determine array layout, mark center of corrugation, and draw a straight line indicating where Mounting Profile will be installed. Double-check the ridge width (minimum of 3/4”) and metal thickness (minimum of 26ga). The screw quantity tables will determine the number of screws needed. Attach the Mounting Profiles using the self-piercing screws and a cordless drill with a ¼” hex socket. The self-piercing screws are applied perpendicular to the roof surface, forming a watertight seal. Next, install End Clamps on the first two Mounting Profiles closest to the eave. Lower End Clamp to the Mounting Profile and “Click” the clamp over the side flanges. Place the first module, align and slide the End Clamp flush with the module frame. Tighten End Clamps and begin installing Mid Clamps. Complete by repeating the steps for each column of modules using the Mid Clamp Clicker as a spacer for consistent E-W gap between modules.

Advantages: The RibFit system is an easy to install, four-component, rail-less solar racking system designed for use on metal roofs. The RibFit system conforms to UL 2703 and consists of an aluminum slide that attaches directly to the top of the metal panel rib. Minimal components and integrated bonding pins reduce installation times when compared to rail-based systems. RibFit mounts modules in landscape orientation and is compatible with most metal R-panel and trapezoidal roof panels with a ridge width of ¾ inch or greater and 26-gauge or thicker. The RibFit system utilizes three levels of watertight protection for longevity and peace of mind.

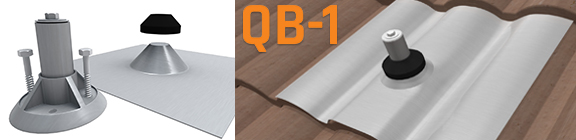

QB-1

Number of pieces: 4

Tools needed: One Tool (½” socket)

How does it install: QB-1 on Tile: QB-1’s strong, versatile post & base make it an ideal solution then mounting solar on tile roofing. To begin, locate each row of mounts and mark them off. Align the vertical fastener holes of the QB-1 Base over the center rafter mark then align the horizontal fastener holes over the snapped row line. Remove the QB-1 Base and place it over predrilled & backfilled pilot holes and secure fasteners. Secure the post to the QB-1 Base.

Once the underlayment is on, install the tile-level flashing, cutting where needed to allow the post to pass through it. Place the cut tile back into position and apply sealant where the post and the flashing meet. Attaching the desired bracket or L-Foot completes the installation.

Advantages: The super-strong and versatile QB-1 rail-based racking system includes a base that attaches to a variety of roof types including composition shingle, tile, shake, slate, and metal shingle. QB-1 is an ideal solution to use for new residential construction projects, as it allows for the roof to be shingled or tiled around the already installed mount. Aluminum cone flashings sized to fit the post are also available. Just combine the base with the post height of your choice (4.5” or 6.5” post heights are available), choose your flashing (12” x 12” or 18” x 18”), then choose your desired bracket.

Smart Conduit Mount

Application: For comp shingle roofs. Rail-based or rail-less applications. Structural or direct-attach.

Material: AL

How does it install? This mount installs quickly on composition shingle roofs and can rotate 360° for conduit runs in any orientation, giving the installer maximum flexibility. The Smart Conduit Mount features our proprietary UltraGrip Technology. A layer of cushioning foam helps to embed the waterproofing sealant deep into the granules of the shingle. Compatible with all conduit clamps (not included).

Key feature: UltraGrip Technology means no need to pry up shingle courses to install metal flashing, and no need to drill pilot holes. Smart Conduit Mount conforms to UL 2239 and UL 2703A.

Frame MLPE Mount

Material: Stainless Steel

Install: The Frame MLPE Mount attaches, mounts and fully bonds module level power electronics (MLPE) to the module frame using a single-bolt clip.

Key feature: This accessory can be used with any racking system to attach the MLPE to the module frame.

Contact: info@ecofastensolar.com

Website | info@ecofastensolar.com | Distributors |

U.S. manufacturing footprint / capacity: Our U.S. manufacturing footprint continues to expand, allowing us to better serve our customers with locally produced solutions. We have a lengthy list of products that are already made in the U.S., and we are consistently adding to that list.

What products qualify for domestic content: Multiple. See “Domestic Content” items in the drop down menu

Notable AVL listings: Sunnova, Sunrun, Amicus, Goodleap, Enfin, Light Reach, EverBright, IGS, Mosaic, Dividend, Posigen, Sunlight, SunStone Credit

Domestic Content Product List

As of Feb. 10, 2025

Clamp

- 4000135-US K2 Cross Clamp Set, Mill, DC

- 4000145-US K2 Cross Clamp Set, Dark, DC

Roof Attachments

- 4000017-US Standing Seam PowerClamp Standard,Set,DC

- 4000307-US Corrugated PowerClamp, Kit, DC

- 4000308-US Trapezoidal PowerClamp, Kit, DC

- 4000282-US K2 Multi Mount Kit, Mill, DC

- 4000284-US K2 Multi Mount Kit, Dark, DC

- 4000630-US L-Foot Slotted Set, Mill, DC

- 4000142-B-US USH +2, 5.5" Base Kit, w/K2 EverSeal, DC

Rail

- 4000819-US CrossRail 44-X Max 172'', Mill, DC

- 4000820-US CrossRail 44-X Max 172'', Dark, DC

- 4000727-US CrossRail 48-XL 172", Mill, DC

- 4000728-US CrossRail 48-XL 172", Dark, DC

- 4000723-US CrossRail 48-X 172", Mill, DC

- 4000724-US CrossRail 48-X 172", Dark, DC

Rail-less: 4000246-US K2 MiniRail Comp 2.0 Kit, Dark, DC

Components

- 4000051-US Rail Connector CR 44-X, Set, Mill, DC

- 4000052-US Rail Connector CR 44-X, Set, Dark, DC

- 4000385-US RailConn CR 48-X,48-XL Set, Mill, DC

- 4000386-US RailConn CR 48-X,48-XL Set, Dark, DC

Splice Foot X & XL

Number of pieces: 3

Tools needed: ¼” Nut Driver

Certifications: UL 2703, UL 441, TAS 100, ICC ESR 3575

How does it install: The Splice Foot X & XL roof attachments are preassembled with K2 EverSeal, a flexible flashing rubber seal. Mark the roof attachment locations on the roof, then simply peel off the protective paper backing and stick it in place. If you’re installing to the rafter, you will need to use two screws in the center holes, if you’re installing to the deck you will need to use four screws in the corner holes. Use a ¼-in. nut driver to install the screws. The provided screws are self-tapping, so pilot holes are not necessary. The screws are designed to pull the butyl into the penetration so that additional sealant is not necessary. Then you’ll use the provided T-Bolt set to attach the CrossRail directly to the attachment. You can also splice the rail with this attachment, in that case you would need to use two T-Bolts.

Advantages: There is no need to pry shingles or nails because the attachment sits on top of the roofing material. There is no need for additional sealant because the product is preassembled with the K2 EverSeal butyl. There is no need for pilot holes since the screws used are self-tapping. You have the flexibility to install to the rafters or directly to the deck. You don’t have to purchase other components to splice two rails together because you can do so directly with the attachment.

Big Foot

Application: Residential or C&I

Components included: T-Bolt Kit and Clip for Chem Link E-Curb

Tools needed: 13mm Socket

Certifications: UL 2703

Installation: Choose the appropriate fasteners for your structural attachment. If needed, drill your pilot holes, seal holes, and secure the Big Foot to the roof. If you choose to use Chem Link’s E-Curb then you will attach the Chem Link Clip on the bottom half of the foot. This is used to ensure proper distance when installing the Chem Link E-Curb. The back of the clip should hit the wall of the E-Curb. Follow Chem Link E-Curb installation manual for detailed steps on how to install the E-Curb.

Advantages: The Big Foot provides a higher profile for clearing obstructions at 6.1" tall. It has a T-Bolt slot in the middle that allows for 1.5" of adjustability. It’s compatible with Chem Link’s 3" E-Curb, which reduces sealant usage, and the E-Curb clip is included in the kit to maintain manufacture warranty. T-Bolt hardware included is also included so you can secure the attachment to K2’s CrossRail systems.

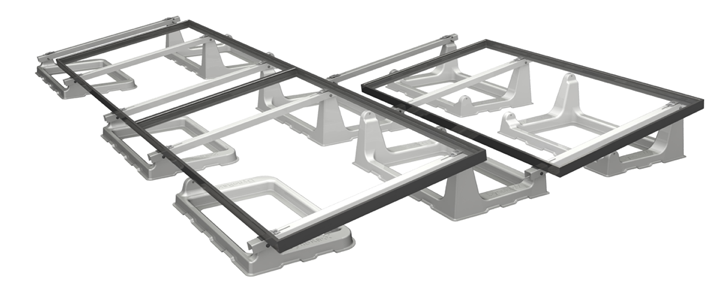

The South Face System

Components included: Chassis with preassembled mats, and Cross Clamp

Tools needed: 13mm socket

Certifications: UL 2703, UL 3741

Domestic content? The clamps

Advantages: The South Face System is K2's innovative south-facing ballasted system with optional anchoring. The roof protection mats feature a built-in patented design that accounts for thermal migration, ensuring durability and performance over time. Additionally, the racking is stackable, which minimizes shipping size and costs, enhancing overall efficiency for installers. Designed specifically for effective solar installation on various roof types, this system maximizes energy capture while remaining lightweight and easy to handle, making it a preferred choice for commercial applications.

How does it install: To install the South Face system, begin by marking the array layout using the K2 Base Report layout diagram. Mark vertical and horizontal lines based on module orientation and chassis layout. Lay out the chassis according to the chalk lines, ensuring the mats align properly. Starting from the southwest corner, set the chassis row by row. Install ballast blocks following the base design, and utilize the South Face anchor bracket for optional mechanical attachment if needed. After placing the modules on the chassis, use the K2 Cross Clamps to secure the modules in place, ensuring each module has at least four clamps. Finally, connect the grounding conductor for safety compliance. This structured approach ensures secure and efficient installation of the solar system.

K2 Conduit Clamp Kits

Application: Both Residential and C&I

Material: Stainless steel

Installation: There are four variations of this product to help you easily install. The first option is to install it on composition shingle roofs, and it comes with a small metal flashing almost identical to the K2 Flash. The second option is to install the clamp with the preassembled EverSeal butyl directly to the roof using a self-tapping wood screw. The third option is to install it directly to the South Face system using the hole directly on the chassis. And the final option is to install the clamp directly to the CrossRail channel using a T-Bolt.

Key feature: Whichever way you prefer to use it, the K2 Conduit Clamp is simple to install with a toolless snap fit design and is compatible with 3/4" or 1" conduit. If installing it to the roof, you can install it directly to the deck. The clamp has a 360 range so you can turn it anyway you need to run the conduit properly.

MiniRail Comp System

Components included: MiniRail Comp Bracket, and Cross Clamp

Tools needed: 13mm socket, 5/16” socket

Advantages: Introducing the MiniRail Comp System: your ultimate rail-less system solution for composition shingle roofs. Featuring K2's proprietary EverSeal butyl, the MiniRail Comp arrives pre-assembled and ready to adhere to your roof effortlessly. It is rigorously tested for reliability through water submergence and accelerated age/weather tests, ensuring resilience in harsh conditions. The sleek 5" design eliminates the need for long extruded rails, while the versatile attachment options allow for either four or two screws for deck or rafter installation. With a low-profile design, the MiniRail Comp integrates seamlessly into your roof, providing a clean look and superior performance for solar installations.

How does it install: To install the MiniRail Comp, start by marking the outer corners and separation lines for the modules based on the chosen orientation. Strike chalk lines to center the MiniRails. After peeling the protective paper off the butyl, position the MiniRail Comp on the marked lines and attach it using the provided screws—four for deck mounting or two for rafter mounting. Secure the Cross Clamps by inserting them into the MiniRail and turning clockwise. Finally, position the solar modules on the rails, ensuring proper alignment and secure with additional clamps, while considering optimal wire management throughout the installation.

Certifications: UL 2703, UL 2703A, ICC ESR Report

Domestic content? Yes

K2 Armor w/ Big Foot Kit

Components included: K2 Armor, Big Foot, Seal Bond 490

Tools needed: 13mm socket, Drill

Advantages: Discover the K2 Armor with Big Foot Kit—a high-quality, German-engineered roof attachment for flat roofs that offers redundant waterproofing with K2 EverSeal. It is ideal for a variety of roof membranes including TPO, rolled asphalt, concrete, and EPDM, ensuring compliance with local codes. This compact and efficient design minimizes pallet and freight costs while providing exceptional durability and stability in diverse environmental conditions. By optimizing your solar installations with the K2 Armor, you ensure a reliable and effective solution tailored for flat roofs, making it a preferred choice for professionals in the solar industry.

How does it install: For optimal butyl adhesion, first clean the roof surface where the Big Foot and K2 Armor will be installed, using the manufacturer’s recommended cleaner if necessary. Select appropriate fasteners for the structural attachment and drill pilot holes. Peel off the protective paper from K2 EverSeal and secure the Big Foot at the desired location without over-torquing the screws. After securing the Big Foot, peel the protective paper from the bottom of the K2 Armor and press it onto the roof surface, leaving a gap for the sealant to fill. Finally, completely fill the K2 Armor cavity with Seal Bond 490 for a watertight seal.

Certifications: UL 2703, TAS 100

Domestic content? Coming soon

K2 Multi Mount

Tools needed: 13mm socket, Drill

Advantages: Designed for both efficiency and ease of installation, the Multi Mount features an open slot design with a retention lip, ensuring rapid and secure integration with rail components. This innovative design allows for a versatile mounting solution suitable for various roof types, enabling the installation of solar panels with less hassle and fewer components. By streamlining the installation process, the K2 Multi Mount Kit minimizes labor costs while maintaining the highest standards of durability and performance. Proudly made in the USA, this version meets the requirements of the IRA 2022 Domestic Content standards, making it an excellent choice for projects that prioritize American-made products.

How does it install: To install the K2 Multi Mount Kit, begin by marking the array layout on the roof and snapping chalk lines for rail locations. Mark the mounting locations over the rafters, ensuring compliance with allowable mount spacing. Clean the roofing surface where the mounts will be placed and peel back the protective paper from the butyl. Position the mount centered over the rafter and secure using lag screws, tightening until the conical washer stops rotating. For deck attachments, use the specified screws and follow similar instructions, ensuring proper engagement with the plywood. Once the mounts are secured, insert the T-Bolts through the slots into the CrossRail, tightening to the specified torque. Lastly, adjust the Rail Runner to the desired height and secure it, repeating the process for additional mounts to complete your installation.

Certifications: UL 441 Section 27 Rain test, TAS 100(A)-95, UL 2703A

Domestic content? Yes

K2 4 Wire Dragon Clip

Application: Suitable for both rail and rail-less systems; applicable in residential and commercial installations across various roof types.

Material: Stainless steel with a UV-resistant nylon body.

Domestic content? Partially

Key feature: The K2 4 Wire Dragon Clip is engineered to attach directly to the PV module frame, providing a secure hold for up to four PV cables or two Enphase Q Cables. Its compatibility with all K2 Systems enhances its versatility and adaptability. The stainless steel construction ensures durability for long-term use, while the UV-resistant nylon body prevents sharp edges from damaging cable insulation. This thoughtful design makes the Dragon Clip an essential component for installers wanting to maintain clean and organized wiring in their solar projects.

How does it install? To install the K2 4 Wire Dragon Clip, first clip the metal bracket piece onto the desired location on the PV module frame. Once the bracket is securely attached, snap your wires into place within the clip. This straightforward installation method allows for quick cable management, facilitating a clean and organized setup for multiple cables while ensuring they are held securely and protected from potential damage.

Certifications: UL 1565, UL 3741

Magerack Solar Mounting System

Components: Rail, Mid Clamp, End Clamp, Roof attachment with rail nut, and Rail splice

Tools needed: 1/2” hex socket

Certifications: UL 2703

Installation: It is a rail-based solar mounting system for solar installation on composition shingle, tile and stone-coated steel roofs.

Advantages: Reliable, easy to install and cost-effective

MageMount Rail-less Solar Mounting System

Components: Roof attachment with MageBolt, and Module Connector

Tools needed: 1/2” hex socket

Certifications: UL 2703

How does it install: It is rail-less solar mounting system for solar installation on composition shingle, tile and stone-coated steel roofs. It has only two components, Module Connector and Comp Foot. Comp Foot is attached to the roof and also secures solar module. Module Connector connects two adjacent solar modules for additional stability and bonding.

Advantages: Lower cost. Easy to ship, carry and install.

L-foot with Flashing

Components: L-foot with Flashing

Tools needed: 1/2” hex socket

Certifications: N/A

How does it install: L-foot with Flashing is roof attachment for composition shingle roof. Flashing is secured by attaching it to the vertical portion of the L bracket with a bolt.

Advantages: It has a unique and patented flashing design with no hole on the flashing surface so it is absolutely waterproof. It has a simple design and is intuitive to install.

C&I metal roof: Rail-less Standing Seam Metal Roof Mounting Kits

Components: Mid Clamp Mounting Kit and End Clamp Mounting Kit

Tools needed: 1/2” hex socket and 3/16” Allen key drive

Certifications: UL 2703

How does it install: Each kit has two components, MageBlock and mid or end clamp. MageBlock is attached to standing seam with two set screws. Mid or end clamp slides on top of MageBlock and secures solar module onto MageBlock.

Advantages: It has only two pre-assembled components, Mid-clamp Mounting Kit and End-clamp Mounting Kit. Each kit is 3”x3”x1” and multiple kits can be packed in one box. The cost is only one-third of rail-based mounting system and it is easy to install.

C&I metal roof: MageBracket RH, RL, CH and CL mounting brackets

Components: One mounting bracket

Tools needed: Hex socket

Certifications: N/A

How does it install: MageBracket RH, RL or CH has two angle-adjustable brackets that can be attached to the side of the rib for better waterproofing. MageBracket CL has two width-adjustable brackets that can be attached on the top of the rib of corrugated metal roof.

Advantages: Angle-adjustable and width-adjustable rib mounting brackets fit most common R-Panel trapezoidal and corrugated metal roofs. They have better waterproofing capabilities and are strong roof attachment with mounting screws attached to the sides of the rib or into the structural element. The optional L bracket is ready to be attached to rails.

C&I metal roof: MageBracket RH/RL Rail-less Mounting Kit

Components: Mid Clamp Mounting Kit and End Clamp Mounting Kit

Tools needed: Hex socket

How does it install: MageBracket RH or RL Mounting Kit is a simple and low-cost rail-less solar mounting system for R-panel trapezoidal metal roof. It has only two parts, mounting bracket and mid or end clamp. The angle-adjustable bracket with EPDM sealant fits most R-panel metal roof and is attached to the side of rib with self-tapping screws for better waterproofing. It utilizes the rib as rail and the bracket creates a mounting platform where the mid and end clamps secure solar panels on top of the bracket.

Advantages: It reduces mounting components dramatically, saves installation time and cost significantly and looks better aesthetically. Similar mounting kits are also available for standing seam metal roof and any metal roof with flat portion on the roof.

C&I metal roof: MageBracket F Rail-less Mounting Kit

Components: Mid Clamp Mounting Kit and End Clamp Mounting Kit

Tools needed: Hex socket

How does it install: MageBracket F Mounting Kit is a simple and low-cost rail-less solar mounting system for R-panel trapezoidal or standing seam metal roof or any metal roof with 3”x4” flat area for each mounting kit. It has only two parts, mounting bracket and mid or end clamp. Mounting bracket is attached to any 3”x4” or larger flat area on the roof with butyl sealant and secured to the deck or structure using up to four roofing fasteners. Universal mid and end clamps fit almost all solar panels.

Advantages: The bracket is attached to roof structure and can withstand stronger wind and heavier load. It reduces mounting components dramatically, saves installation time and cost significantly and looks better aesthetically.

MageFoot Rail-less Mounting Kit for Composite Shingle Roof

Components: Mid Clamp Mounting Kit and End Clamp Mounting Kit

Tools needed: Hex Socket

Certifications: N/A

Installation: MageFoot Rail-less Mounting Kit is a simple and low-cost rail-less solar mounting system for composite shingle roof. It has only two parts, mounting foot and mid or end clamp. Mounting foot is deck-mount bracket with butyl sealing gasket on the bottom. It can be attached to roof deck with four mounting screws or to structural element such as rafter with two lag screws. The mid clamp has integrated bonding capability to bond two adjacent solar modules when tightened. The universal end clamp fits all framed solar modules. It reduces mounting components, lower shipping cost, saves installation time and cost and looks better aesthetically.

Advantages: MageFoot Rail-less Mounting Kit is a simple and low-cost rail-less solar mounting system for composite shingle roof with only two parts, mounting bracket and mid or end clamp. It can be mounted on deck or to rafter. It reduces mounting components dramatically, saves installation time and cost significantly and looks better aesthetically.

Training program: New Certified Installer Program offers online training teaching pro-level skills and rewards installers for every completed job.

U.S. manufacturing footprint / capacity: Pegasus has domestic supply for all of its rails, having established domestic rail suppliers for several years. Pegasus also has established domestic supply of fasteners – both clamps and mounts – with shipments beginning in Q4 of 2024.

What products qualify for domestic content: Pegasus Rail, Pegasus Max Rail, Pegasus Multi-Clamp, Pegasus ButyL-Foot (for composite roofs), Pegasus Scissor Mount (for tile roofs)

What notable AVLs are you listed on? Sunnova, Goodleap, Enfin

Pegasus SkipRail System

Components included: Pegasus Rail (or Max Rail), Splice (or Max Splice), Dovetail T-bolt, Multi-Clamp, SkipRail Clamp, SkipRail Kickstand (optional), Hidden End Clamp (optional), End Cap (or Max End Cap), MLPE Mount, Cable Grip, Wire Clip.

Tools needed: Driver with ½” socket

Domestic content? Pegasus Rail, Max Rail, Multi-Clamp, ButyL-foot

Advantages: Pegasus SkipRail eliminates entire rows of rail, mounts and roof penetrations. SkipRail saves the average crew 1500 roof penetrations, 11,000 feet of rail and 10,000 lbs of material per year! SkipRail makes the best rail system even better, simplifying workflow and reducing strain. The SkipRail Clamp automatically levels and bonds modules row-to-row. One system for all roofs: Works with comp, tile, metal, low and steep slopes. Easily work around roof obstructions. Mixed portrait/landscape arrays. Install Pegasus SkipRail in most geographies. For high load areas, use the SkipRail Kickstand clamp, or just Pegasus Rail with traditional dual-rail method – it’s the same set of SKUs!

How does it install: Install the first row of panels using the traditional dual-rail method. For the second row (and additional rows), install just the top rail. Attach the SkipRail Clamp to the first row of panels. Lower the next-row panel into SkipRail Clamp. When tightened, the SkipRail clamps automatically levels and bonds the panels row-to-row. And with the open channel rail, easily secure wire management.

Certifications: Pegasus SkipRail System – UL2703; LTR-AE-001-2012; ASCE 7-05, 7-10, 7-16, 7-22 PE certified; Class A fire rating for any slope roof; FL Cert of Approval FL41396

InstaFlash2

Components included: Instaflash2, with 2-6 fastener screws required for installation depending on deck/rafter attach (screws sold separately)

Tools needed: Driver with ½” socket

Certifications: IBC, ASCE/SEI 7-16 & 7-22

Domestic content? Pending

Advantages: InstaFlash2 is the ultimate comp roof attachment. Anchor to rafters or direct to deck. It features a pre-installed, non-hardening sealant for an instant, watertight seal in almost any weather, even rain. Installs in temps from 0-170° F. A protective cage keeps hands and tools clean while directing sealant exactly where it needs to go. Sealant is automatically compressed into all gaps and butt joints, ensuring a watertight installation every time. InstaFlash requires no pilot holes or flashing, making it simple to use, even for new crews. Install with confidence, extend your season and get a perfect seal every time.

How does it install: Release Safety (allows sealant to be disbursed). Install screw through center hole and drive until InstaFlash2 pushes through cage and seats onto roof. If first screw hits rafter, drive second screw in the hole above. Rafter installation complete. If first screw misses the rafter, install a second screw to the left or right hole. Continue until 2 screws are embedded in rafter. For deck attach, use 6 screws.

BondBox

Components included: BondBox includes integrated ground lug for up to 3 wires

Tools needed: Driver with ½” socket. Hole cutter. Screw driver.

Advantages: BondBox is a next-level junction box that eliminates ground lugs and copper wire from the roof. BondBox electrically bonds the rail to an integrated ground lug. Simply connect your ground wire to the lug. Includes additional openings for grounding multiple arrays. Connections can be made mid-wire. A thick aluminum bracket secures BondBox to the rail, providing an enduring connection that won’t fail. BondBoxes are stackable for easy transport, contain weep holes for drainage, no-slip feet for steep roof traction, and a slot for WAGO 221 connectors. Use pre-installed form to capture array details for future reference.

How does it install: After installing Pegasus SkipRail system, click BondBox into Pegasus Rail. Fasten bolt. Drill through one of pre-marked locations for conduit. Install conduit. Insert ground wire into the grounding bus and tighten screw. Finish wiring arrays. Write installation details on the pre-installed site capture label. Close and fasten BondBox.

Certifications: UL2703 and UL1741

Tile Scissor Mount

Components included: Deck sled 5/16” SS lag screws, and single-form flashing (Flat, S, and W shapes). Mounting scissor bracket. EPDM boot.

Tools needed: Drill, driver with ½” socket.

Advantages: The Pegasus Tile Scissor Mount simplifies installation on tile roofs with a revolutionary squeeze-lock. Eliminate the L-foot and connect to rail in a single tightening step. Tile Scissor Mount provides replacement flashing, so installers can cut time, not tiles. Works for S, W and flat tiles. The elevated, double-seal EPDM boot and single-form flashing ensure a watertight connection for life. Flashing lip blocks wind-driven rain and the off-set cone improves drainage. Comes with a 25-year warranty.

How does it install: Remove tile. Use template to mark location for deck sled. Pre-drill. Install flashing and deck sled using driver with ½” socket. Set appropriate flashing (S, W, or flat). Insert Scissor bracket, click into place. Cover opening with EPDM boot.

Certifications: ASCE 7-16 and TAS 100(a)

InstaTilt

Components included: Upper and Lower Tilt leg brackets (Use with InstaFlash mounts, sold separately)

Tools needed: Driver with ½” socket.

Certifications: IBC, ASCE/SEI 7-16, UL2703

Domestic content? Pegasus Rail, Pegasus Max Rail

Advantages: Pegasus InstaTilt is a next-level mounting system for flat roofs. Instantly save money by using scrap rail that otherwise would be recycled as the tilt legs. It features pre-assembled parts, installs superfast and incorporates scrap rail to reduce waste and eliminate SKUs. InstaTilt is compatible with InstaFlash mounts for watertight installation in almost any weather. Instantly set a tilt angle from 0 to 35 degrees, and fine tune the array alignment without removing modules.

How does it install: Mark array attachment locations for desired spacing locations. Install InstaFlash2 mounts. Cut Pegasus Rail (or Max Rail) scrap to desired length. Attach scrap to InstaFlash2. Connect Upper Leg Bracket. Attach Lower Leg Bracket to InstaFlash2. Install Pegasus Rail (or Max Rail) onto Lower and Upper Tilt Legs. Install PV modules using Pegasus Rail components.

U.S. manufacturing footprint / capacity: SnapNrack partners with industry leading manufacturing partners across the United States to provide best in class product quality and supply chain reliance to our customers.

What products qualify for domestic content: SnapNrack is now offering a full suite of domestic content solutions for the Ultra Rail and TopSpeed Universal Systems. We are currently the only racking manufacturer offering both rail & railless domestic solutions. The Ultra Rail & TopSpeed Universal Systems will qualify for both Rail & Fasteners MPCs.

SnapNrack Ultra Rail

Number of pieces: 5 (Rail, Mount, Splice, Mid Clamps and End Clamps)

Tools needed: ½” socket with an impact gun for all connections and attachments

Certifications: UL 2703 for Grounding/Bonding, Class A Fire Rating Type 1 & Type 2 Modules, UL Certified Modules, Stamped Structural Engineering Reports

How does it install: Installation of SnapNrack Ultra Rail is intuitive and easy to learn. After the array is marked in accordance with the design plans, Umbrella L Feet lag into rafters with patented flashing technology that protects against roof leaks. Rails snap into mounts with spring loaded features to allow the rail to easily slide and be adjusted to the desired location and height. Finally, panels are placed on the rails secured using SnapNrack’s proprietary mid and end clamps as wires are nestled securely into the rail channel.

Advantages: The Ultra Rail profile creates a channel for wires, unobstructed by splices or mounts. It doesn’t rely on zip ties which can fail over time creating opportunities for wire damage or worse. Spring loaded brackets allow the rail to snap into place and be released, without tools, and easily slide prior to leveling and tightening. SnapNrack doesn’t rely on T-Bolts that can bind or be improperly installed, resulting in a system failure. Roof penetrations are protected with a patented cone flashing feature that extends above the base of the roof attachment and sealed under a proprietary Umbrella Lag.

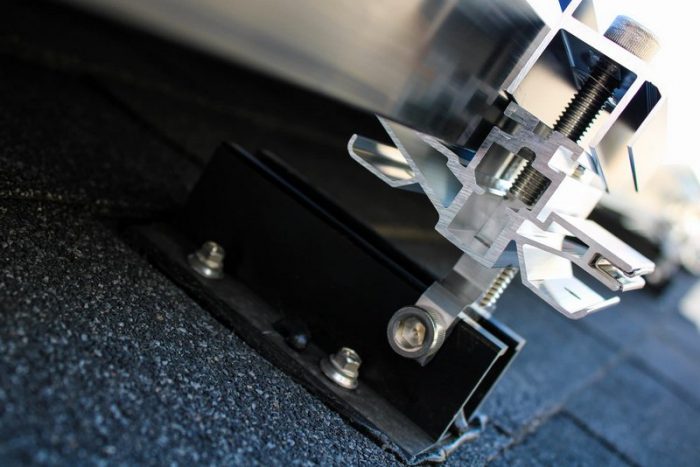

UltraFoot for Ultra Rail

Components: UltraFoot with a 0.25” butyl pad. Optional Fasteners: SnapNrack DeckAnchor, Standard 5/16” lag screw, #14 wood screw, #14 self-tapping steel fasteners, 3/8” wedge anchors

Tools needed: ½” socket with an impact gun for all SnapNrack connections and attachments

Advantages: With UltraFoot™ SnapNrack has expanded roof sealant methods with pre-installed butyl pads for easy peel & stick installation, eliminating composition shingles disruption. SnapNrack butyl pads are industry-leading at 0.25” thick, and have passed TAS 100 Wind Driven Rain Testing, ensuring the attachment is fully sealed, and watertight. Roof attachments with butyl remove the need for additional sealant during install, streamlining the process, and saving time for installers while ensuring a secure, weatherproof attachment. Maintaining familiar SnapNrack traditions of single tool installs, DeckAnchor™ has a ½” hex head. Wide threads securely grip roof sheathing and significantly reduces the potential for over-tightening.

How does it install: Engineered with butyl, now installers do not have to add sealant to the bottom of the mount, simplifying the installation process and further protecting the roof. The UltraFoot has pre-installed butyl for easy peel stick installation eliminating disruption to composition shingles, and this butyl pad is an industry-leading 0.25” thick allowing installation over shingles without cutting extra pieces of butyl. The new UltraFoot is available in three configurations to accommodate rafter and deck mounting based on DeckAnchor or wood screw install preferences. All ships pre-assembled with the new Ultra Rail Flip Clamp Mount that centers the load over the fastener and creates an easier snap-in experience with UR-45 Rail, especially UR-45 Mill Rail

Certifications: The SnapNrack Ultra Rail Mounting System is certified to UL 2703 standards for Grounding/Bonding, Class A Fire Rating Type 1 & Type 2 Modules, UL Certified Modules, Stamped Structural Engineering. The UltraFoot™ with DeckAnchor™ has passed TAS 100A wind driven rain and ASTM D7147 structural tests and will soon have Florida product approval for use in High Velocity Hurricane Zones (HVHZ). Additionally, the DeckAnchor™ was tested by means of ASTM D1761 standard test methods to generate screw capacities.

Domestic content? Yes. Refer to the SnapNrack Product Catalog and reference SKUs with “-USA” to note as a domestic content product.

TopSpeed Mounting System

For: Residential

Components included: TopSpeed™ Mount & TopSpeed™ Clamp, ½” SnapNrack Wood Screw, uses existing SnapNrack Universal Skirt & Spacers, and railless Wire Management

Tools needed: ½” socket with an impact gun for all connections and attachments

Certifications: UL 2703 for Grounding/Bonding, Class A Fire Rating Type 1 & Type 2 Modules, UL Certified Modules, Stamped Structural Engineering Reports

How does it install: The simplified process consists of 3 basic steps: On the ground TopSpeed Mounts are attached directly to the panels in the approved mounting locations. Then, while still on the ground, wire management begins with SnapNrack Smart Clips and MLPE Frame Kits to prep module leads & MLPEs, resulting in a faster mounting install experience. While these steps are being performed on the ground, array layout & the first row of TopSpeed Mounts with the Universal Skirt are installed. Installers are then ready to install at TopSpeed. All mounts are secured to the roof with SnapNrack’s ½” wood screws after modules are positioned in desired location.

Advantages: The majority of the TopSpeed install process is performed on the ground. Except for the first row of mounts for the Universal Skirt, all TopSpeed Mounts are attached directly onto the modules before the module is brought up on the roof. TopSpeed is fundamentally changing the installation process to cut down on roof layout, staging material, and assembling of racking. This installation process also cuts down the amount of time installers are exposed to safety risks by spending long periods of time on the roof. TopSpeed brings the process to the ground for a safer experience.

AnchorFoot and DeckAnchor

Components included: AnchorFoot with a 0.2” butyl pad

Optional Fasteners: SnapNrack DeckAnchor, Standard 5/16” lag screw, #14 wood screw, #14 self-tapping steel fasteners, 3/8” wedge anchors

Tools needed: ½” socket with an impact gun for all SnapNrack connections and attachments

Certifications: The SnapNrack Ultra Rail Mounting System is certified to UL 2703 standards for Grounding/Bonding, Class A Fire Rating Type 1 & Type 2 Modules, UL Certified Modules, Stamped Structural Engineering. The AnchorFoot™ with DeckAnchor™ has passed TAS 100A wind driven rain testing, and the DeckAnchor™ was tested by means of ASTM D1761 standard test methods to generated screw capacities.

How does it install: AnchorFoot & DeckAnchor together are designed to reduce the number of roof fasteners when fastening directly to roof sheathing and to provide flexibility to mount anywhere on the roof, including rafters or purlins. Engineered with butyl, now installers do not have to add sealant to the bottom of the mount, simplifying the installation process and further protecting the roof.

The AnchorFoot has pre-installed butyl for peel & stick installation, eliminating disruption to composition shingles. Flexible installation options include: fastening to roof sheathing with (2) DeckAnchors or (4) #14 wood screws, rafter mounting options with (1) 5/16” lag or (2) #14 wood screws. Multiple other fasteners can be used including #14 self-tapping steel fasteners. Ships pre-assembled with Ultra Rail Mounting Clamp for easy rail attachment.

Advantages: SnapNrack butyl pads are 0.2" thick, and have passed TAS 100 Wind Driven Rian Testing. Roof attachments with butyl remove the need for additional sealant during install, streamlining the process, and saving time for installers while ensuring a secure, weatherproof attachment. Maintaining familiar SnapNrack traditions of single tool installs, DeckAnchor has a ½” hex head. Wide threads securely grip roof sheathing and significantly reduces the potential for over-tightening.

SnapNrack RL Universal

Number of pieces: 4 (Mount, Link, Skirt & Spacers)

Tools needed: ½” socket with an impact gun for all connections and attachments

Certifications: UL 2703 for Grounding/Bonding, Class A Fire Rating Type 1 & Type 2 Modules, UL Certified Modules, Stamped Structural Engineering Reports

How does it install: RL-U is designed such that each install step is independent, where a single installer can install the entire system. The roof attachments are a Flash Track which provides North-South adjustability, secured with a single Umbrella Lag through SnapNrack’s patent pending Umbrella Flashing. RL-U only requires a single RL-U Mount SKU, which is used at all locations on the array. The integrated RL-U Skirt attaches to the first row of mounts, creating a strong structure for leveling and aligning the array. The RL-U Links clamp onto the top of modules securing them in place while providing row-to-row bonding, and provide an attachment point for 2-4 modules. A single installer can drop modules into place, and secure them across the top without having to reach down the roof across a module.

Advantages: RL Universal is designed to provide the fastest, most intuitive install experience on the roof. The direct mount system features four basic components, with nothing larger than the size of a module, resulting in easy material management. Features include an integrated Skirt for a secure installation with sleek aesthetics, Universal Mounts used at all locations on the array & Links that can accommodate 2-4 modules. Mount & Link interference is eliminated with the unrivaled Mount offset & Link adjustability. RL-U is the only railless system to offer labor saving installation processes backed by the industry leader in residential solar.

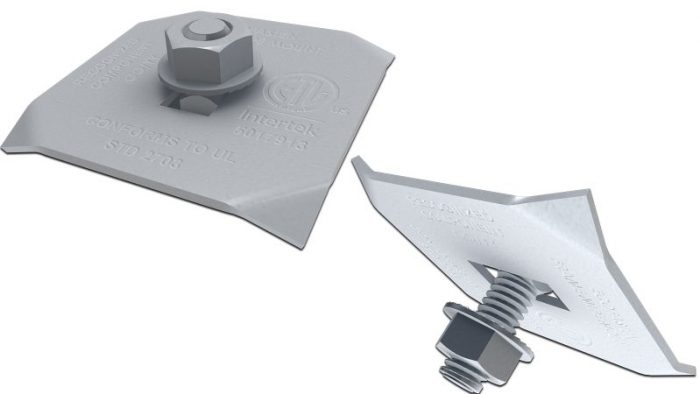

SnapNrack SpeedSeal Technology

Number of pieces:

- 2 (SpeedSeal Foot or SpeedSeal Track & Lag Screw) OR

- 5 (SpeedSeal DeckFoot or SpeedSeal DeckTrack & 4 Wood Screws)

Tools needed: ½” socket with an impact gun for all connections & attachments for Foot & Track with Lag

Certifications: UL 2582 Wind Driven Rain Test and ASTM E2140 Water Column Testing standards, Miami-Dade NOA No: 20-1104.01, UL 2703 for Grounding/Bonding, Class A Fire Rating Type 1 & Type 2 Modules, UL Certified Modules, Stamped Structural Engineering Reports.

How does it install: SnapNrack SpeedSeal Foot & Track allows installers to lag straight to a structural member with no in-between components, and eliminates damage to shingles from the installation process. The simple install process consists of locating a rafter, filling the sealant cavity and securing to the roof. The SpeedSeal Technology takes over, compressing sealant into the cavity, shingle surfaces and lag hole, as the SpeedSeal Foot or Track is secured to the rafter. The SpeedSeal DeckFoot & DeckTrack mount directly to the deck, making installation even faster by allowing installers to lag straight to the roof deck & eliminating the need to find a rafter.

Advantages: The SpeedSeal Technology portfolio save installers time on the roof with less parts and tools, while maintaining the integrity of the shingles. Metal flashing requires the use of a pry bar to “rip up” the shingles and remove nails. SpeedSeal eliminates this, so the roof remains intact, the way meant it’s meant to be, all while faster. The new SpeedSeal DeckFoot and DeckTrack provide further time savings due to their ability to by mounting directly to the roof deck. Installers no longer need to find rafters and seal missed pilot holes.

Universal Wire Clamp

Material: All components to the Universal Wire Clamp are made of materials that have been selected for their ability to handle high UV exposure and extreme rooftop temperatures common under solar arrays in order to last the life of the system. It is backed by the SnapNrack 25-year Manufacturer’s Limited Product Warranty.

Install: A 1/2-in. socket is all you need to install the SnapNrack Universal Wire Clamp. The Universal Wire Clamp attaches to the rail channel by snapping in a channel nut and securing a single bolt with a 1/2-in. socket. The Wire Clamp installs with the same tool as the rest of SnapNrack’s Ultra Rail System.