Solar PV module size matters – but efficiency matters more

Today’s homeowner is less concerned about the “first cost” of a residential PV system than the “total cost” over time. In fact, recent Harris poll data commissioned by LG found that 70% of consumers are willing to pay a premium of several thousand dollars to receive a better long-term payback.

While DC capacity is important, it’s critical to understand module efficiency to ensure you’re delivering the right technology to your customers. Explaining “total cost” and system yields over time can generate increased revenues and higher customer satisfaction for your business.

Cells sell

Often overlooked in the residential sales process, but vitally important to the efficiency and long-term reliability of a solar module is its cells. At a high level, there are three main types of cell architecture: N-type, P-type, and Hetero-junction (HTJ). P type is the most common, accounting for approximately 80% of global cell capacity. P-type PERC has been widely adopted because it is generally less expensive to manufacture and faster to scale. However, there are a few downsides for use in residential applications, such as P-type’s susceptibility to light induced degradation (LID), which is why users see a first-year degradation allowance on most modules of 3%.

N-type and HTJ allow for higher conversion efficiencies than P-type and, due to their different technology, they don’t experience LID. First-year degradation allowance of these modules are typically less than 2%.

Another noteworthy technical differentiator is that N-type and HTJ cells are inherently bifacial without any additional process steps.

This means that their conversion efficiency is typically higher than P-type cells, even when assembled into modules with white backsheets. White backsheets do allow for some light transmittance and can produce measurable “back side” energy yield with N-type cells, which means the kW/kWh conversion efficiency is higher than P-type PERC modules. Higher conversion efficiency translates to more energy production and higher yields over the life of the system.

The final important point to consider is to consider how the cell is designed to remove energy generated by the cell out of the cell. A high number of busbars and back contact cells are less susceptible to greater power loss if exposed to micro-cracking as the percentage of the cell not generating power by this micro-crack is minimized. This, along with physical and chemical properties, helps substantiate the lower warranted degradation rates of N-type and HTJ modules.

Economic impact for customers

The two major drivers of economic performance due to long-term value are the production of the module (typically reflected in its kW/kWh conversion ratio) and its long-term degradation characteristics.

While typical P-type PERC have an allowable degradation rate of 0.7% per year, an N-type will have a warranted degradation rate around 0.33%. While those fractions of a percentage may seem inconsequential, over time they add up. For instance, at year 25, a 0.7% d-rate warranty has a system performing at 80% of its nameplate capacity, whereas the LG warranty structure, for example, is 90%.

Take a 10-kW rooftop array that has a guaranteed degradation of no greater than 0.3% per year versus a similar 10-kW array with a 0.7% annual degradation rate. The array with the 0.3% rate will yield over $12,000 more in electricity generated, assuming 0.15 avoided cost on Day 1, escalating at 3% PA. When you factor in rising energy costs over time, the long-term performance characteristics of N-type cells have an even greater effect in the array’s financial metrics.

If you’re using a third-party proposal generating tool, it’s important to ensure that you’re using actual module parameters versus system defaults.

While system defaults represent an approximation of the parameters, they’re rarely going to be completely accurate, especially depending on the tool being used. Defaults that typically cause accuracy issues include kW/kWh conversion ratio, Y1 degradation rate and Y2+ degradation rates.

Inaccuracies can result in one of two negative outcomes. If the default model is overly conservative, and you underbid the customer, you’re essentially leaving money on the table. However, another potentially devastating outcome is an overly aggressive model, which results in overselling the customer. If this is the case, the signed agreement between the installer and customer is at risk of breach of contract. This could leave the installer at risk of irreparably damaging trust, or even worse, being sued for misrepresentation.

Is Bigger better?

As more manufacturers unveil 66 cell modules (or their 132-half-cell counterparts) that are larger in footprint than traditional 60 cell modules, it’s important to look past the upfront nameplate rating. Check module efficiency, and more importantly, ensure you’re using proper dimensions when laying out an array. With setbacks, the extra six to eight inches on a module can actually lower DC capacity in certain instances.

The other critical factor to consider is racking and Balance-of-System (BOS) compatibility.

If your crews are field fabricating rack because it’s too short for these longer modules, your module savings can quickly be canceled out by increased installation time, BOS costs or if you need to design and install with higher performing micro-inverters or optimizers, which are designed for these higher wattage modules.

Sales teams should be able to explain the difference to homeowners that a higher DC capacity of a module doesn’t necessarily translate to a more efficient system, or even a longer-term yield. Using the kWh value of the power generated over the life of the system is the great equalizer because this is how the customer truly understands what will offset their utility bill (which is what they are looking for).

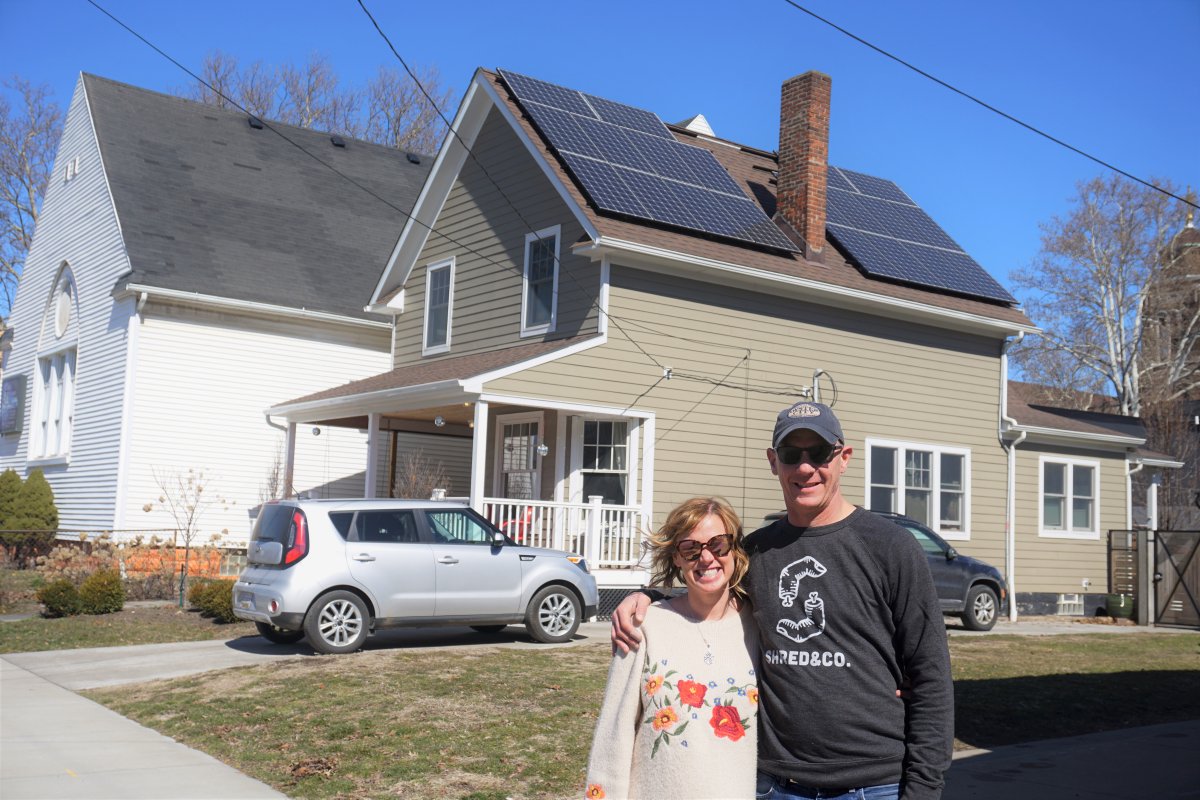

Solar builder experts play a critical role not just in installing PV systems, but in educating consumers about the benefits of going solar. The average homeowner won’t understand the reasons that N-type cells are better than P-type or the trade-offs between efficiency and capacity. They just need to know from their expert installer that they are making the best investment for the long term.

Brian Lynch is head of solar business development, LG Business Solutions USA.

Comments are closed here.