Rate the return: How SIFT calculates hundreds of solar site models in seconds

The beginning of the solar project development cycle is time- and resource-intensive. Third-party civil engineers are needed to perform granular topographical site assessments, which is often a manual process. Plus, developers are often considering multiple plots of land at once, requiring engineers to evaluate all scenarios on each plot.

That detailed topographic assessment is a must, but new technology is emerging to dramatically speed up that site selection without skimping on the detailed topo assessment.

Terrasmart’s Solar Instant Feasibility Tool, or SIFT, is one such example. Today, Terrasmart design engineers use SIFT to help developers and EPCs bring in system design, performance, and financial modeling early in the project cycle. SIFT helps them identify the right racking system and optimize the layout to increase energy yield, returns, and value.

SIFT has already been applied to 250 GWs of potential capacity to streamline slope analysis and optimize solar tracker site design from the start by rapidly simulating thousands of different layouts in minutes. Asset owners have reported 5% to 15% higher returns on their projects as a result.

Here’s a deeper look at how Terrasmart’s SIFT tool works, and how it has impacted solar tracker site plans and installation.

SIFT in action

SIFT iterates through multiple cost/benefit scenarios to analyze racks with varying slope flexibility and evaluate their impact on construction costs — modeling hundreds of layouts, conditions, performance goals, and financial scenarios in seconds.

Users can optimize configurations and components, import their own module and inverter data from multiple industry databases, and run IRR and LCOE models. Instead of running multiple manual iterations, Terrasmart system engineers use SIFT to shave weeks off design work, analyzing hundreds of project layouts, conditions, performance goals, and financial scenarios in minutes.

For example, SIFT is used to understand when a 2P tracker versus a 1P tracker are needed to maximize production or minimize land grading and keep construction on track.

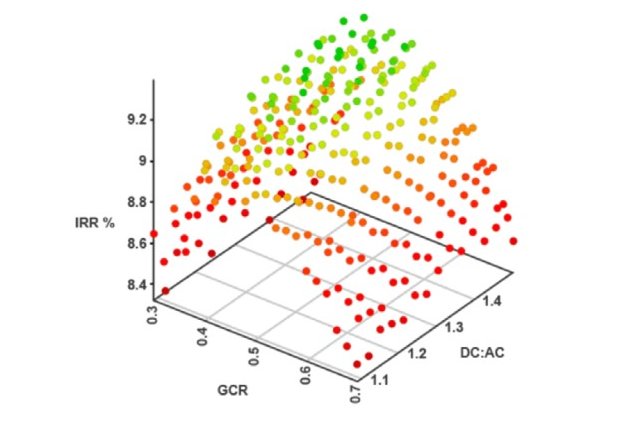

Here’s a SIFT generated heat map of hundreds of layout configurations, representing the trade-off between the row spacing (GCR), DC:AC ratio and rate of return (IRR).

Reducing grading and civil costs

It’s critical to understand quickly what the different impacts are between trackers that allow for 10%, 15%, or 20% slope tolerances. That’s why Terrasmart uses SIFT to analyze how a site’s topography will alter project costs and production yield.

Using elevation data from USGS, SIFT quickly identifies areas that require grading, given a rack’s slope tolerance. Heat maps show where racks can be installed for any given cut-and-fill parameter and can update the map by changing a rack’s tolerance in seconds.

Any SIFT user can load average local and regional labor costs into the tool to help calculate site-specific budgets for moving each cubic yard of earth. For example, developers and EPCs can set a target of a maximum 15% grade for the entire site, prompting SIFT to determine how much earth needs to be moved — and how much that likely will cost.

Case studies

To see how developers have used SIFT, and the results they’ve seen, read the rest of this white paper from Terrasmart. Tags: software, Terrasmart

Comments are closed here.