Nearly 70% of U.S. solar EPCs fall short on quality, HelioVolta report finds

Independent inspections reveal that poor construction quality makes corrective maintenance six times more likely

Nearly 70% of solar EPCs are falling short on quality standards, according to independent technical service provider HelioVolta. That’s the jaw-dropper from HelioVolta’s annual SolarGrade PV Health Report, which includes the largest publicly available benchmark of U.S. solar contractors based on independent field inspections.

“Frankly, our findings are profoundly disappointing. As solar advocates, our team is pained to report that most projects we inspect will underperform or even fail our findings go unaddressed,” said James Nagel, COO of HelioVolta. “We’re publishing our analysis to drive the industry to higher quality standards. The best EPCs in our dataset prove we can do better.”

Said another way: unplanned, unbudgeted corrective maintenance is six times more likely to occur in their projects if workmanship errors are not remediated.

The SolarGrade PV Health Report summarizes third-party data from 5 GWs of solar assets in over one thousand projects built by nearly 120 subcontractors and 70 EPCs — 52% of projects analyzed were new construction and 48% assessed operating assets.

David Penalva, CEO of HelioVolta, notes that the findings are timely as U.S. developers face expiring federal incentives for solar assets. Tax credits backstop initial revenues when projects miss energy production targets – a backstop that will largely disappear by 2027.

“As the era of guaranteed profits ends for the American solar market, the era of limited oversight must end with it,” Penalva says. “In the future, when projects are valued on their lifetime energy yield alone, widespread construction defects that are ignored today will be the hallmarks of unprofitable portfolios.”

HelioVolta Quality Standard

HelioVolta developed the report using the HelioVolta Quality Standard (HQS), a proprietary methodology that categorizes contractor performance by issue severity and frequency. HelioVolta’s field engineers use SolarGrade software to document inspections and standardize observations across regions, contractors, and system types.

The HQS is applied to EPCs by averaging issue per MWDC rates of all inspected projects. EPCs qualify as Above HQS when all inspected projects:

- Do not contain critical and major issues. These are significant safety risks that require urgent remediation and costly truck rolls.

- Do not contain more than 10 issues per MWDC. In normal operating conditions, unscheduled corrective maintenance is unlikely because issues are addressable during scheduled preventative maintenance.

No EPC rated Above HQS, but some projects did. To learn more, download the full 2025 SolarGrade PV Health Report.

Standout SolarGrade stats

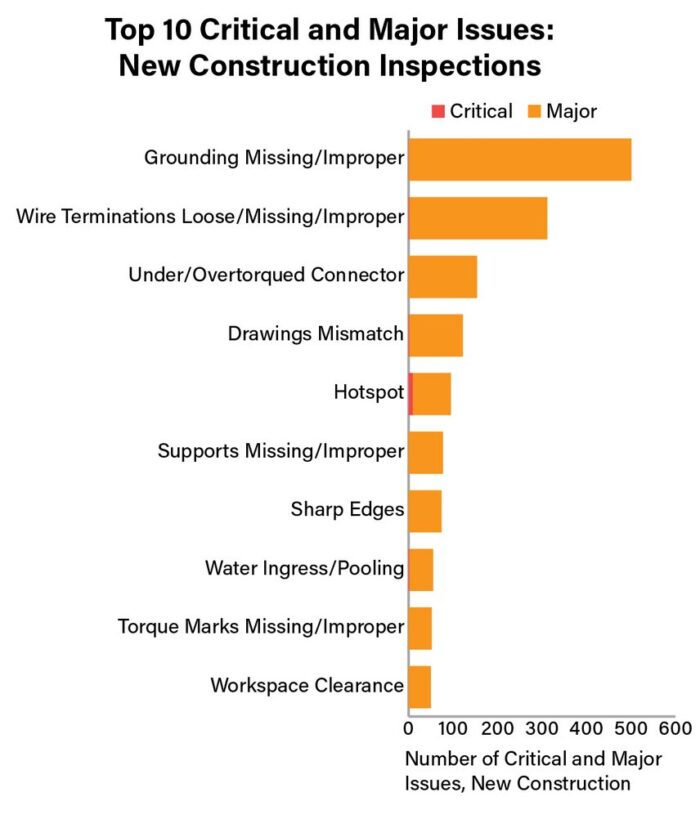

- 85% of projects analyzed for the report contained major issues that require urgent corrective action

- 7% of projects had critical issues that triggered immediate de-energization (partial or total) and same-day remediation. See our Roofs of Hazard coverage for more on the rampant issue with PV connectors.

- HelioVolta observed wiring- and connector-related issues in 80% and 83% of projects respectively. Connector-related issues did improve by 3% since the 2024 SolarGrade PV Health Report.

- Projects less than 5 MWDC have 109.48 issues per MWDC on average while projects over 100 MWDC have just 0.45 issues per MWDC on average! What gives? The sample of total number of projects is smaller in the HelioVolta database, but the report posits that the standard construction protocols and rigorous regulatory requirements of large-scale projects bump up average quality standards per MW.

How to spot a quality EPC

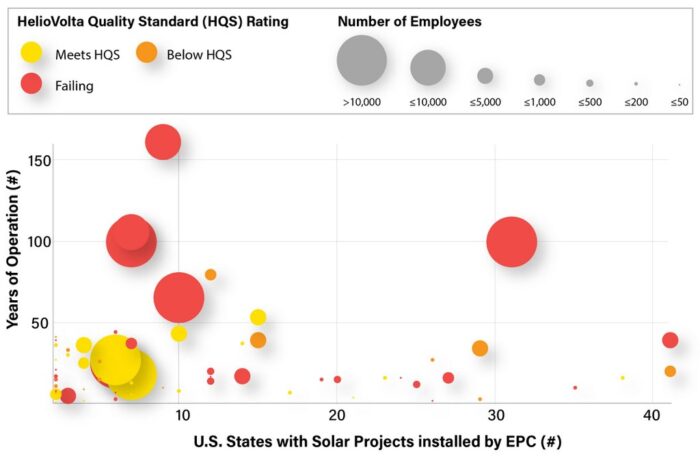

The report underscores that contractor experience, size, and geographic reach are not reliable predictors of quality.

The report also isn’t demanding perfection. Instead, clear construction standards, third-party inspections, and proactive communication between stakeholders deliver the best outcomes.

“Truck rolls skyrocket and profits plummet when construction quality is an afterthought,” said Amanda Bybee, CEO of Amicus O&M Cooperative. “The cliché is true: an ounce of prevention is worth a pound of cure. If asset owners want to hit revenue targets, projects must be built right the first time. Today’s O&M budgets cannot cover extensive remediation.”

To Bybee’s point, the HelioVolta report notes that minor and negligible issues originating during construction do not pose urgent failure risks as long as they are corrected by O&M teams during preventive maintenance to expedite project handoff. But “the longer these issues go uncorrected, the higher the risk of costly failures and system underperformance.”

EPCs that participated in third-party quality programs demonstrated a 48% reduction in issues per MW over time, validating that measurable quality improvements are achievable when they are prioritized.

Comments are closed here.