Report: Steel frames can reduce embodied carbon of solar PV modules vs. aluminum

Domestic supply and lowered emissions often go hand in hand — even when it comes to replacing aluminum solar PV module frames with steel. Steel is historically an energy intensive, CO2-heavy production process, but new research indicates a steel PV frame solution could reduce solar module production embodied GHG emissions by 87% over the industry’s ubiquitous aluminum frames that typically are all imported from China and Southeast Asia.

The report, released by Boundless Impact Research and Analytics, underscores the critical role domestic steel sources can play in rebuilding and securing domestic PV module capacity and supply chains.

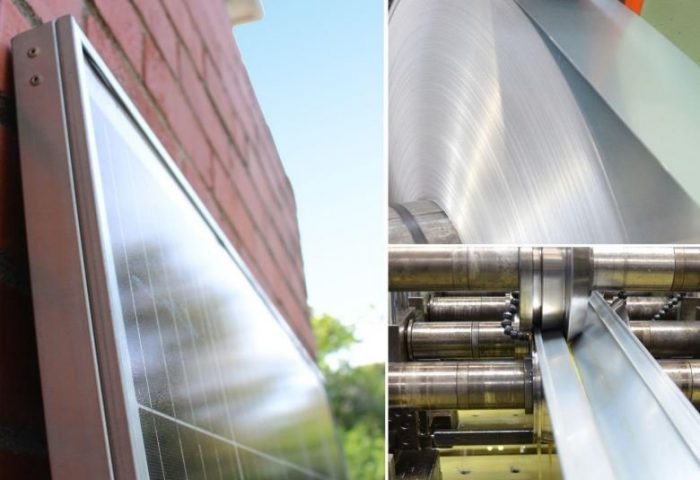

The steel frame concept specifically cited in the research is a patent-pending concept from Origami Solar. which uses a steel rolling forming process which creates a frame with intricate folds, hence the name “Origami Solar.” The company says the frame is backwards compatible with existing aluminum frames and “will meet or exceed all UL and IEC standards.”

According to the report, Origami Solar steel module frames produced in the United States, using 100% recycled steel, delivers an 87% reduction in GHG emissions compared to aluminum module frames and a 94% reduction when produced in Germany, which more widely utilizes renewable energy in manufacturing.

The estimated Fossil Energy Footprint of Origami Solar’s steel module frame is 137 megajoules (MJ) per 1-by-2-meter frame, compared to 815 MJ for a conventional virgin aluminum frame produced in China using an extrusion production process.

The potential GHG emission savings resulting from replacing only 10% of the industry’s conventional aluminum solar frames with Origami Solar steel module frames is approximately 30 megatons (30 million metric tons) between 2022 and 2030. This is equivalent to the emissions of eight coal-fired power plants for an entire year. A 50% shift to steel would result in a GHG reduction of 148 megatons.

“If the U.S. does not rapidly seek energy independence backed by secure domestic supply chains, it will find itself overly reliant on imported materials,” said Gregg Patterson, CEO of Origami Solar. “This report points to American steel as the answer to a renewable energy future. And since steel is abundantly produced on every continent, this solution is a global one. Steel makes clean energy cleaner, and it is essential to the path to domestic energy security.”

This announcement comes shortly after Origami advanced to the final round of the U.S. Department of Energy’s American-Made Solar Prize competition. One of 10 Hardware Track teams named finalists, Origami was awarded a $100,000 prize to advance its innovation from proof-of-concept to production-ready for the final phase of the contest. Origami will present its solution one more time at the DOE’s Go! Demo Day in September 2022.

Comments are closed here.