Overcome C&I rooftop obstacles with the right mounting system

Commercial rooftop solar jobs are commonly plagued by everything else already up on that roof. Vents, water lines, gas lines, electrical conduit on block supports and HVAC line sets, etc., as well as unforeseen surface undulations, can all conflict with the optimal solar layout. Many leading edge mounting systems can be too low to simply go over top these nuisances, but there are exceptions.

Sollega’s FR510

The leading edge height of Sollega’s FR510 is higher than most (6 inches with its 10dg and 8 inches with its 5dg and 6dg). Those few extra inches can clear a lot of obstacles in that list. Also, because Sollega’s system is modular and mounts four modules to each bucket, there are no obstructions from the racking on the short or long rail to obstruct.

The FR510 weighs 4.6 lbs requires just one size tool for installation. All four clamps holding the modules are top mount, and being an install-as-you-go system leaves the roof open and free of trip obstacles.

“The key feature is there is no assembly required,” says Elie Rothschild, CEO of Sollega. “The racking arrives ready to install. But a big factor that is commonly not talked about is the efficiency of shipping. We injection mold in California and can fit 750 kW of racking in a 53-foot container. Our pallets are 25-30 kW each and are designed to be easily lifted to the roof with a grade all.”

The FR510 has flexibility to handle roof undulations too and can be adapted in the field to work around obstacles that were not accounted for in the initial design. If necessary, the tilt angle and inter-row spacing can be easily changed in the field by simply moving the bolt/nut/square washers to different holes in the bucket, allowing the installer to effectively reduce the inter-row spacing by a few inches and fit in a sub array which wouldn’t fit otherwise. There are additional benefits too. Bi-facial modules get a boost because there is nothing blocking the back of the module such as rail or wind screens. This also means better airflow and less module derating due to heat on the roof.

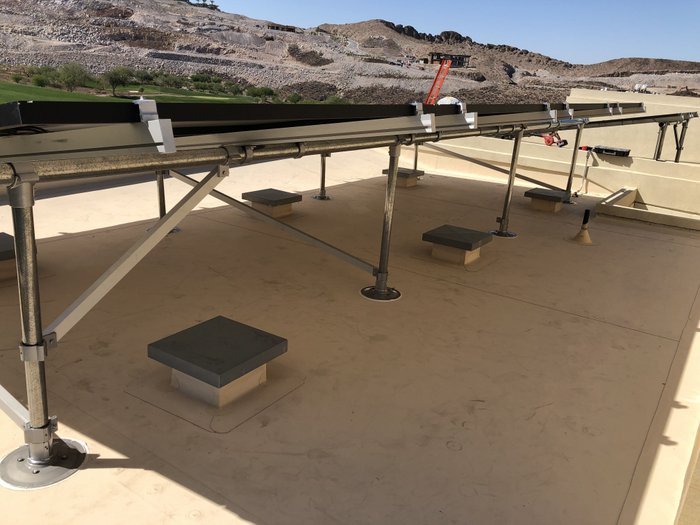

SunModo’s SunTurf

Another option is to rise way above literally any roof obstacle and go for a super dense layout with SunModo’s SunTurf Roof Mount. The system easily achieves leading edge heights of 7 feet or more and provides convenient access to roof surfaces for maintenance and repair.

“Commercial solar often uses tilt up multi-row designs which has a major effect on the requirements for anchoring,” notes Cliff Schrock, engineer with SunModo. “Support of the solar by the structure is increased and uplift of multi-panel arrays requires stronger anchoring for most commercial designs.”

By spanning over roof obstructions, the system takes full advantage of the available roof surface therefore maximizing the PV system size and increasing your ROI. An example is the 16.83kW Bethany Lincoln Sol-Up Project:

“The SunTurf Roof Mount system allows the installer to span arrays continuously above roof obstructions, greatly increasing panel density on the rooftop,” says Peter Abou Chacra, engineering consultant with SunModo. “The ability to attach to the deck or rafter further simplifies this feature by allowing the installer more flexibility to locate SunTurf posts strategically on the roof.”

But Schrock notes any solar installation using a tilt-up type design, or ones with multiple arrays (2X, 3X, 4X) on a single rack should be anchored into the building beam system. There are some exceptions such as the large multi-screw U-Anchor which may allow some smaller multi-arrays on low pitch commercial roofs.

“SunModo has many years of experience which includes interaction with dozens of structural engineers to accomplish residential and commercial designs,” he says. “This experience has allowed us to design mounting systems to satisfy the requirements for solar mounting on various roofs, and in various wind and load situations. Our product line has evolved from the challenges of this experience.

Be sure to look out for more unique rooftop mounting systems in our Rooftop Mounting / Racking Buyer’s Guide, out next week.

Comments are closed here.