OMCO Solar, Entegrity Energy partner on 15-MW Arkansas solar portfolio

OMCO Solar, through its partnership with Arkansas-based Entegrity Energy Partners LLC, will supply its OMCO ORIGIN tracker for 15 MW of solar projects in the state. Since its premier at Solar Power International in 2019, OMCO Solar’s ORIGIN factory-direct tracker has offered operational benefits and economic value for more than 30 projects in multiple states.

“Achieving more together than we can alone — that’s the power of partnerships, and that’s Entegrity,” said Eric Goodwin, OMCO Solar’s director of business development. “Not only are they true experts in driving solar energy adoption across multiple industries, they are also passionate about enabling a sustainable future. Their desire to create learning opportunities to support the growing solar workforce shows their belief in renewable energy’s future. We look forward to working with Entegrity to complete these projects and more in the future.”

OMCO Solar’s first installation with Entegrity benefitted The Cedar Ridge and Midland School Districts, providing clean power from a 1.36-MW co-located solar array.

“When we partner with OMCO Solar, we can rest easy knowing that we are providing our customers with a top-notch solution that will also optimally function with components from other leading providers,” said Charles Maddox, director of procurement at Entegrity. “We’ve had some impactful and important opportunities together. We feel confident that OMCO Solar will be long-term partners as we continue designing and implementing solutions that fulfill our mission of creating a more resilient future.”

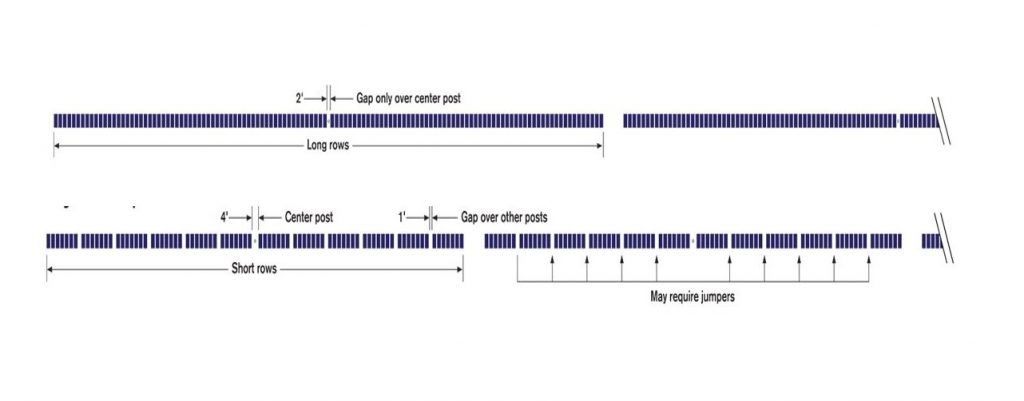

OMCO Solar’s ORIGIN tracker offers developers several main benefits, such as allowing for long rows (up to 120 modules) and eliminating or minimizing gaps over posts, between modules and at row ends. In addition, OMCO Solar manufactures its own torque tubes, which allows for domestic control of the supply chain with nationwide distribution at a reduced cost. This is significant because the torque tube can be one of the most expensive pieces of a tracker system, in some cases up to 25% of the tracker cost.

Comments are closed here.