Fraunhofer Institute leads promising solar cell recycling effort (new PERC cells show 19.7 efficiency)

This is the type of breakthrough the PV recycling sector needs. PV recycling today is largely focused on plugging discarded modules into the reprocessing streams for aluminum, glass and copper. The actual silicon solar cells themselves don’t fit into the equation, but German researchers are ready to change that. The Fraunhofer Center for Silicon Photovoltaics CSP and the Fraunhofer Institute for Solar Energy Systems ISE worked together with the largest German recycling company for PV modules, Reiling GmbH & Co. KG, to develop a solution to recycle PV modules on an industrial scale and reuse the silicon to produce new PERC solar cells.

With this process, the groups say it is possible to recycle all crystalline silicon PV modules, regardless of manufacturer and origin.

Prof. Dr. Peter Dold, project manager at Fraunhofer CSP, explains: “If this were not the case, then this would be far too much work for the recycling companies. It was important for us to develop a scalable process that makes economic sense. A lot is possible in the lab, but our new process should prove itself in the practice for the recycling industry.”

In the first trial, the solar cell conversion efficiency was 19.7 percent.

“This is below the efficiency of today’s premium PERC solar cells, which have an efficiency of around 22.2 percent, but it is certainly above that of the solar cells in the old, discarded modules,” says Dold, putting the initial results into context.

This is a timely development for Germany in particular. Most PV systems in Germany were installed between 2009 and 2011 during the first wave of PV expansion. Currently, around 10,000 tons of silicon in discarded PV modules end up on the recycling market annually in Germany, and that figure will rise to several hundred thousand tons per year by 2029.

“This expansion will foreseeably be followed by a first wave of disposal twenty years later, around 2029, when the feed-in tariff for the installed PV modules expires,” explains Prof. Dr. Andreas Bett, Institute Director of Fraunhofer ISE. “Therefore, it is necessary to establish adequate processes and proce-dures for recovering the silicon material from the discarded modules at an early stage.”

The process

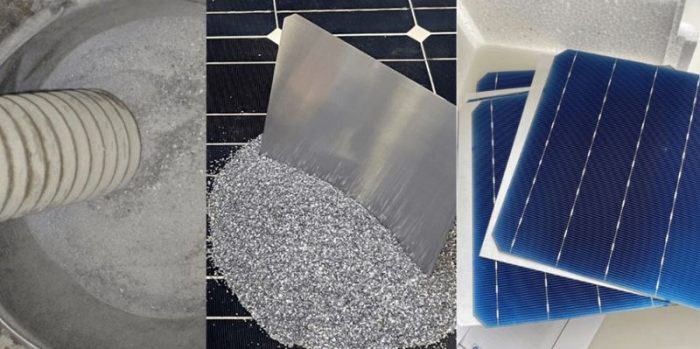

Solar cell fragments are separated and collected from by-products of the mechanical recycling process, which is already established. At Fraunhofer CSP, the cell fragments with sizes from 0.1 to 1 millimeter are first freed from the glass and plastic by various sorting processes. This is followed by the step-by-step removal of the backside contact, the silver contacts, the anti-reflective layer and finally the emitter by wet chemical etching. The silicon cleaned in this way is processed into monocrystalline or quasi-monocrystalline ingots in standard processes and then into wafers.

The crystallization is carried out with 100 percent recycled silicon without the addition of commercial ultrapure silicon. The wafers made of recycled silicon were fabricated into PERC solar cells at Fraunhofer ISE’s PV-TEC.

Comments are closed here.