Why fire departments and AHJs are pushing back on 9540A

Energy storage systems (ESS) with lithium-based batteries are crucial to the solar industry and the energy transition. Lithium-ion batteries also pose fire risks due to their potential to go into thermal runaway, which is why fire codes and standards are a major area of focus and scrutiny in the industry, specifically UL 9540 and 9540A.

We covered the concerns and risks of installing unlisted batteries in a recent feature, “The lithium battery MESS.” Batteries and ESS that undergo 9540A testing and get listed under UL 9540, though, have proven to this point to be safe – but that listing, and that track record, isn’t enough for a growing number of authorities having jurisdiction (AHJs) and fire departments.

What 9540A testing does: Tests battery cells for their thermal runaway tolerances, and the ability of an ESS system to contain that thermal runaway event. Analyzes the off-gases produced leading up to and during a thermal runaway event.

What 9540A doesn’t do: Ignition-based “large-scale fire testing.”

That lack of “large-scale fire testing” in UL 9540 is drawing the scrutiny of fire departments and AHJs, specifically for installations looking to exceed the spacing and capacity requirements specified in fire code (NFPA 855).

The Mayfield Renewables Education Summit, Oct. 2-3, covered 9540 in serious depth, and the permitting pushback was the hottest topic among attendees. Luckily, Solar Builder has the scoop as the exclusive media partner. Here’s a complete summary of the current test standards, what AHJs and fire departments are pushing back on, and what the industry is doing about it, based on my notes and conversations at The Summit.

UL 9540A at a glance

NFPA 855 says an ESS must be tested to 9540A or an “equivalent test standard”. There isn’t one of those, so sourcing product tested to 9540A and listed to UL 9540 is the only way to comply with fire code.

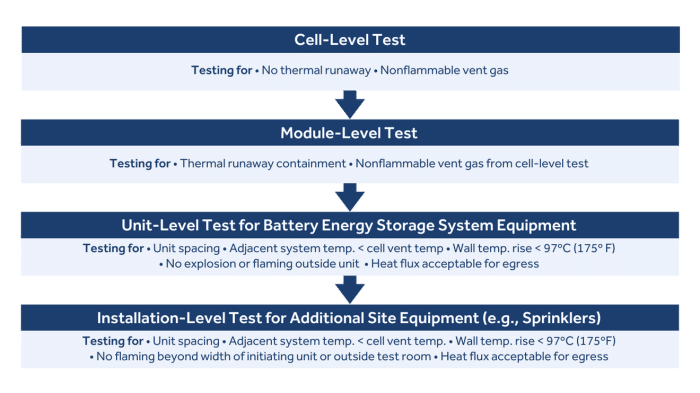

9540A testing involves four test levels – cell level, module level, system level and installation level (which is for larger-scale ESS containers). The goal of each test is to understand and quantify the risks of thermal runaway.

Each test level starts the same way, at an individual cell. Temperature is increased on this one cell with a thin-film heater, which in turn increases pressure inside the cell. The goal is to drive a series of exothermic chemical chain reactions that feed one another, releasing heat and gasses. The testing is meant to verify whether thermal runaway can be achieved, and if so, what the associated fire and explosion risks are.

Theoretically, a battery cell could meet the performance criteria at the cell level test by not being driven into thermal runaway AND not producing flammable off-gases, and that would be it. But NO lithium-based battery – not even LFP despite what manufacturers might tell you – is immune to being driven into thermal runaway at the cell and module level tests.

The cell test generates important data to understand the operating tolerances of that cell.

“The data more important than thinking of the tests as ‘pass/fail,” noted Lucas Miller, Senior Engineering Consultant with Mayfield. “You want to figure out how a battery can be driven into thermal runaway and what the composition of off-gases will look like. This data will be used to design the rest of the system, including gas detection and other fire and explosion mitigation strategies.”

AHJs can permit more under NFPA 855 …

AHJs shall be permitted to approve groups with larger energy capacities or smaller group spacing based on performance criteria from fire and explosion testing. For a manufacturer to list reduced spacing between units in their installation instructions, that spacing must be validated through lab tests.

In 9540A testing, ESS brands can set themselves apart for how well they mitigate that thermal runaway condition.

ESS manufacturers can complete the 9540A test with closer spacing of battery units to prove the ESS is capable of exceeding the 3 ft minimum in NFPA 855 and earn a UL 9540 listing to those specifications.

… But many AHJs are permitting less

Several ESS products have UL 9540 listed systems that met the 9540A performance criteria for spacing components closer than 3 feet – but several fire departments and AHJs do not care.

The San Jose Fire Department really took the lead here. In their view, thermal runaway testing is not equivalent to “large-scale fire testing,” and their contention for ESS units to be installed closer than the 3 ft spacing minimum, or with a battery capacity that exceeds the 20 kWh maximum, they must perform large-scale fire testing.

This term – “large-scale fire testing” – appears in International Fire Code (IFC) 1207.1.15. The IFC language often mirrors NFPA, but this language is inconsistent with NFPA 855. The IFC indicates large-scale fire testing “induces a significant fire into the device under test.”

In short: What happens if we set this thing on fire? 9540A does not answer that, and the San Jose FD and several other jurisdictions in California want that answer before approving an ESS installation that exceeds the limitations in NFPA 855.

Here is a list I gathered, during the Summit, of jurisdictions and utilities that are now looking for “large-scale fire testing,” according to presenters and attendees:

- San Jose

- Santa Clara

- San Francisco

- Santa Cruz

- PG&E

- LADWP

There are likely more. Check with your AHJ and fire department.

Enter 9540B

The off gases produced by a lithium-ion battery going into thermal runaway are flammable. So, requesting some kind of fire testing seems reasonable enough to me.

“First responders would rather have a known fire than a gas detonation waiting to happen,” noted Tyson Bittrich, presenting on the topic at the Summit.

Problem is, there is no agreed upon “large-scale fire test” for a residential ESS. The installation-level test of 9540A essentially tests a full electrical room setup that includes fire protection system like sprinklers. It is well beyond the scope or capability of a residential ESS system.

Enter 9540B. This is a prospective “large-scale fire test” for residential BESS, first released in May 2024. It will be performed in addition to 9540A thermal runaway propagation testing. The hope is this will generate the large-scale fire data for fire officials, including fire propagation from one unit to an adjacent unit. “So, if there is any off gassing that extends out, we can light it on fire and ensure it doesn’t spread.”

Change is coming to the 2026 language of NFPA 855 as well. “There is talk of changing Chapter 9 and adding intentional ignition to assess fire propagation hazard … moving into fire propagation.”

In the meantime …

- “Loop in fire officials right away to validate ESS location and sizing,” Miller and Bittirch recommended. “Build a network of knowledgeable fire protection engineers.”

- Avoid field evaluation. Stick to UL listed products.

- Compile all test reports with engineer interpretation, listings and safety guidelines from manufacturers.

- NYSERDA fire code recommendations are seen as a good guide here. The Kern County Fire Department energy storage review guide was recommended several times for any AHJ seeking Hazard Mitigation Analysis (HMA).

- Manufacturers can also start to perform tests that go above and beyond 9540A requirements with a testing lab. Word at the Summit is that Sungrow has conducted an ignition-based fire test.

Comments are closed here.