“The Roof is on Fire!”

Making sure you never hear those words concerning rooftop solar arrays can be as simple as installing smaller inverters.

By Paul Bundschuh

The commercial rooftop PV market is one of the largest segments of the solar industry and contributes to a substantial, and continously growing, percentage of electrical energy supply. As the industry matures, fires resulting from commercial rooftop PV systems are a growing concern. The solution to the problem comes down to identifying the root cause — a blindspot.

The Blindspot

Existing U.S. commercial PV inverter systems can only detect faults on the ungrounded conductor and not on the grounded conductor. A revision to the UL-1741 standard that regulates PV inverters is currently being considered to eliminate this blindspot. Today, the standard requires PV inverters to detect and respond to faults that can cause fires. This protection is provided by ground fault detection and interrupt (GFDI) fuses.

However, the existing regulations and inverter products have several issues that have been identified from recent PV fires, the main being undetected faults on the grounded conductor. If a PV system initially has a fault on the grounded conductor, it will go undetected. By itself, the grounded conductor fault cannot start a fire, but if an additional fault occurs later on the ungrounded conductor, the GFDI protection will not stop the current flow and a fire can occur. PV inverters need to detect for faults on both the grounded and ungrounded conductor.

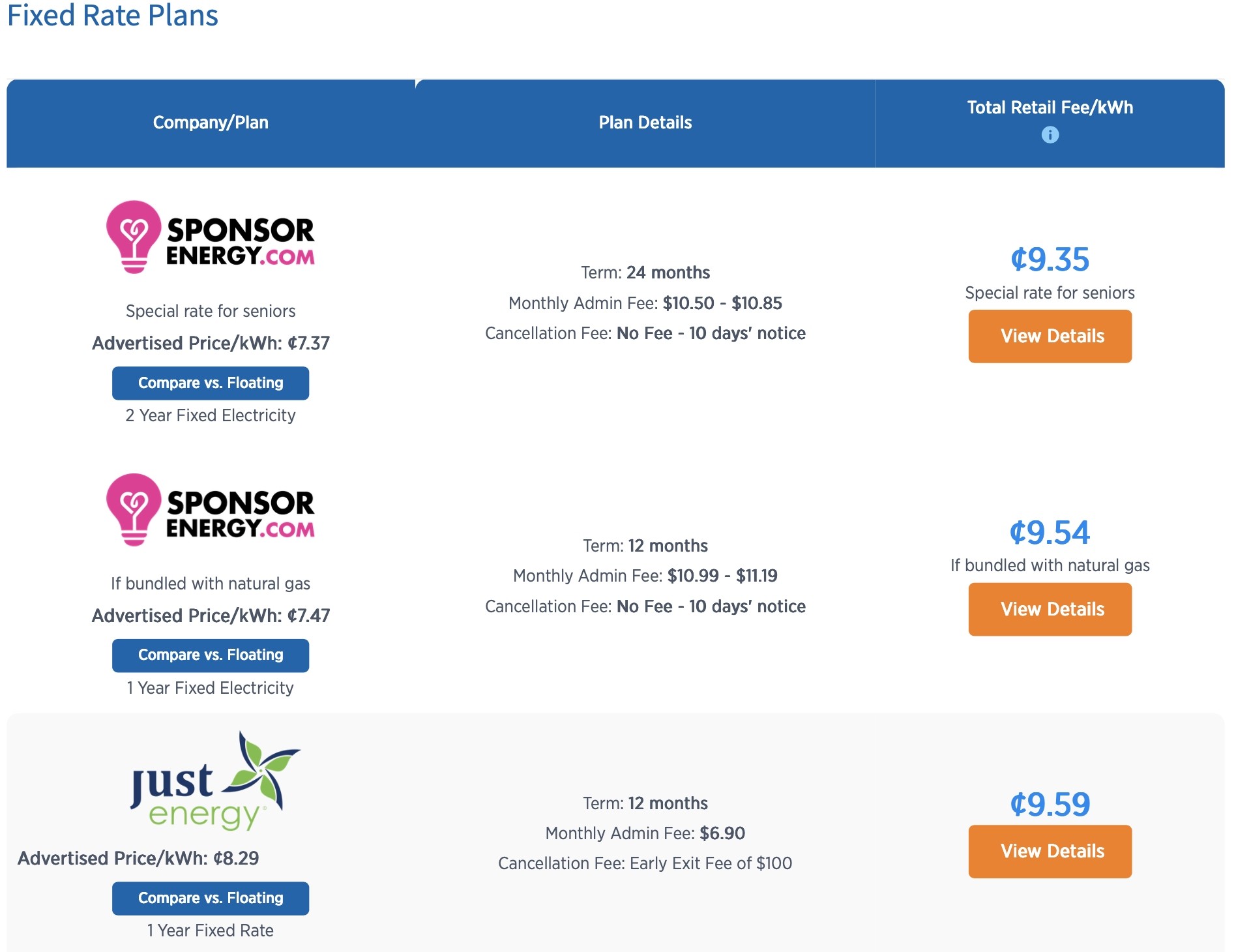

A secondary issue is that large commercial rooftop arrays normally use large commercial-scale inverters (100 kW and larger) that have large GFDI fuses in the range of 3 to 5 Amps. These large fuses have low GFDI sensitivity, which is required to reduce false trips from the 100-kW arrays. The sensitivity of the GFDI protection needs to be increased to the range of 0.3 to 0.5 Amps, which is similar to small residential PV inverters.

Eliminating the Blindspot

Some PV installation firms suggest that expensive field upgrades may be required for both existing and new systems until PV inverters have been redesigned to eliminate this blindspot in fault detection. But there is a new commercial PV inverter solution available that solves these problems without any additional inverter or installation cost. Ideal Power Converters (IPC) has developed the IPV-30kW-480 PV inverter that weighs only 94 lbs compared to the 1,200-lb conventional 30-kW 480VAC 3-phase inverters, and it provides fault detection on the grounded conductor, which eliminates the blindspot.

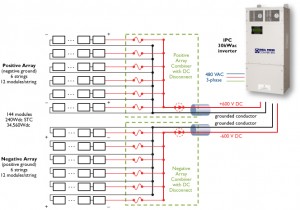

A typical array configuration for IPC’s 30-kW inverter (seen at right) operates with a bipolar array design using matching postitive and negative arrays. Each array has a grounded conductor, and the ungrounded conductors have opposite polarity.

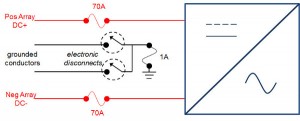

Inside the inverter, both grounded conductors are connected together to a common 1-Amp GFDI fuse. Each grounded conductor has an electronic disconnect switch, which allows the system to lift or disconnect the grounded conductor. The electronic disconnect is normally open when control power is not applied. During the inverter power up sequence, in the morning or whenever the inverter is restarted, the voltage on each grounded conductor is checked prior to closing this switch. If the voltage is abnormal, a fault on the grounded conductor is detected. The inverter will not start and a fault on the grounded conductor will be reported.

Increased GFDI Sensitivity

The inherent blindspot in commercial-scale PV inverters is more problematic by the common practice of using large 100-kW-sized inverters with high DC currents and large GFDI fuses on rooftop arrays ranging between 100 kW and 1 MW. These systems normally have DC input current to the inverter in the range of 200 Amps and DC fuses in the range of 300 Amps. Large GFDI fuses in the range of 5 Amps are required to eliminate nuisiance trips.

Typically, if GFDI fault currents of 2 to 3 Amps occur during the initial grounded conductor fault, this will be too small to trip the large GFDI fuse. Reducing the relative size of the inverters is one approach to increase GFDI sensitivity and safety. Large rooftop PV arrays can still be supported, but they would use an increased number of smaller inverters.

The solar industry is rapidly maturing, and fire safety is one of the issues where the industry needs to respond to concerns. IPC has developed and is offering a simple off-the-shelf solution to this problem in its new inverters without additional installer cost or effort.

Paul Bundschuh is vice president of business development at Ideal Power Converters, located in Spicewood, Texas. For more info, visit www.idealpowerconverters.com.

Comments are closed here.