Choosing the Right Inverter

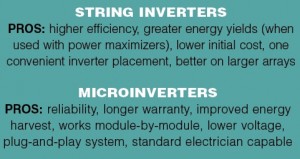

String inverters and microinverters both come with their pros and cons. Determining which is best for a residential or small commercial project really comes down to customer preference.

Inverter manufacturers definitely consider each other competitors, but they’re colleagues all the same in the fight to take the solar industry to the next level. The push for grid parity will only come from the collective support of all solar companies. Solectria Renewables, a grid-tied PV inverter manufacturer, wants to be the top inverter company, but it also gives credit when it’s due to its colleagues. With microinverters, like those produced by Enphase, taking a bite out of the market, it’s obvious the advances over the last few years have been a fantastic boost to the industry. Choosing between a microinverter and a string inverter for residential and smaller commercial applications is a decision determined by design, costs and safety.

Shade: Solar Power’s Worst Enemy

Solectria builds commercial, three-phase inverters, mostly in the 10-kW to 500-kW range. Scott Bowden, director of business development, says the real growth in the industry has been in the commercial/utility space, and those small but large inverters have been great business for all companies, not just Solectria. But microinverters are carving out a niche in the market, too.

Microinverters attach to the backside of modules which can make for quick replacement with little downtime depending on the installation.

“I tip my hat to Enphase for having really stuck to their guns and developed and gained a lot of market share in the residential segment of the business. They’ve done a great job,” he says. “People ask if we’re worried about competing against Enphase — I’m sure we lose some business to microinverters; we see the advantage in it.”

One of the largest advantages of microinverters is their ability to work module-by-module. Rooftop designs and shading can completely cripple a system run through a string inverter. But with microinverters, that weakness is nonexistent.

“If you have a complicated roofline with any shading issues, like a 200-year-old elm tree you just can’t cut down, microinverters are great to deal with shade,” Bowden says. “With a string-by-string [array] on a residential home, you may only have two strings. One shade could kill half of your production for that afternoon. Absolutely, microinverters shine when it comes to complicated roofs with all kinds of obstructions.”

Bowden says he understands that most projects 3 kW or smaller will be microinverter territory, and that range is expected to grow. But if someone is interested in a large residential rooftop install, that usually means the roof is large and facing South — perfect for solar generation and more than likely avoiding shade and thus utilizing a larger, string inverter.

Costs and Incentives Change the Game

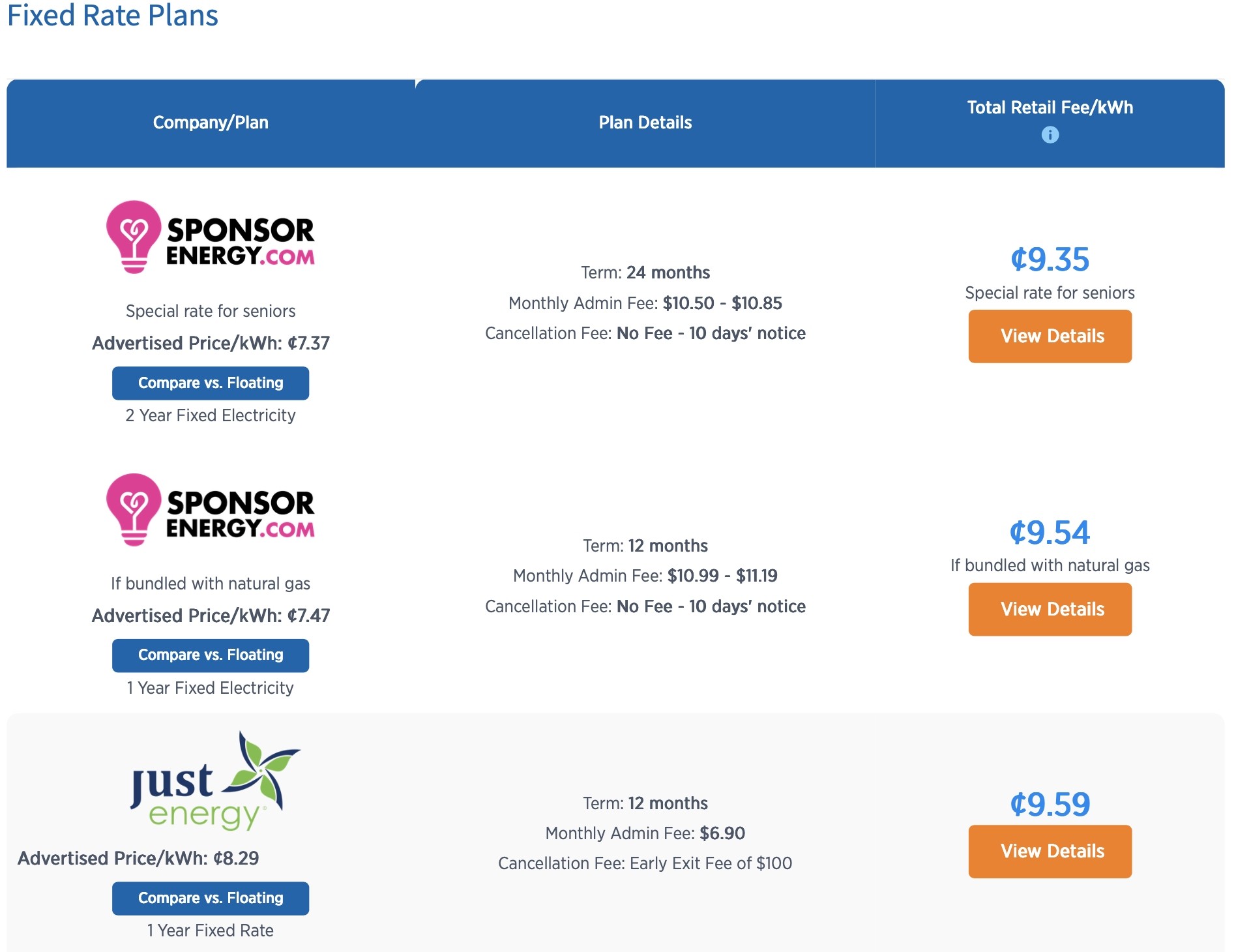

Based on the incentives across the country, it’s not the best decision to build an array in bits and pieces. It’s more practical to build the complete package all at once.

“Typically, you size your roof, you can get 5 kW up there, you’re going to buy a 5-kW system, get the federal tax credit and the state incentives, do the paperwork once and you’re done with it,” Bowden says. “But at some point in time, the ability to start an array and add to it little by little [will be] great. That’s perfect for microinverters.”

Without considering available incentives, the overall cost of a system is really what determines whether a customer will go with a microinverter or a string inverter. Raghu Belur, co-founder and vice president of products of Enphase Energy, says the end customer benefits more from a microinverter from the value it brings and the reduced cost of energy.

Without considering available incentives, the overall cost of a system is really what determines whether a customer will go with a microinverter or a string inverter. Raghu Belur, co-founder and vice president of products of Enphase Energy, says the end customer benefits more from a microinverter from the value it brings and the reduced cost of energy.

“A microinverter-based system produces more energy, is more reliable, is much easier to design, install and manage and is safer,” he says. “Just from a financial decision standpoint, the levelized cost of energy (LCOE) is much better to install a microinverter. The big advantages of greater energy yield, greater reliability and easier install design and management are what drive the financial benefits.”

Bowden says microinverters are viable solutions for any size array except when it comes down to cost per watt.

“Everyone is trying to get to grid parity. We need to bring down costs on the inverter,” he says. “It’s a lot easier for us on a single 500-kW inverter to get our costs down per watt than it is to sell a whole bunch of microinverters — it just doesn’t equate.”

Safety During and After Installation

Safety is a large issue in the solar industry as in any industry. Belur says with microinverters, there are no string designs and no high voltage management, providing safety to the installer and anyone else who comes in contact with the solar power system.

“[Enphase’s microinverter] is an AC system at 240 V. That’s what you see running around in all your outlets in your house,” he says. “With a traditional system like the string inverter, you have to deal with up to 600 V DC running around on your roof and that has some significant challenges to it.”

String inverter manufacturers understand their “high risk” product isn’t as attractive as a microinverter, but Bowden says he’s more concerned with the safety risks after installation. He says residential solar installers typically work to finish their projects within one day to make money and move on to the next project. That way they’re only setting up ladders and staging and getting everyone into fall arrest equipment once.

If a microinverter goes down, it doesn’t immediately have to be fixed, but eventually the customer will want it replaced. Will the technician come out and put on a fall arrest system and anchor down again by lifting up shingles? Safety could be a real issue, Bowden says. The serviceability and safety of microinverters is well known, but what installer shortcuts are taken to get there?

“If you start to have failures of microinverters on the roof of a residential home, it’s so much easier to replace a string inverter that is typically mounted on an outside wall in a detachable wiring box,” he says. “You can walk up from the truck without any ladders and disconnect the inverter, pull it off and pop a new power head in, tighten it down, put the old unit in a UPS box, ship it back and you’re done. You’re not climbing on a roof, trying to get under modules to repair a microinverter.”

Different customers have different preferences when it comes to purchasing inverters for both residential and commercial projects. Microinverters may promise higher energy yields than its string cousin, but their initial costs sometimes turn buyers off. A little competition between inverter companies is fine, as long as more solar power generation is the end product.

Comments are closed here.