Cable hangers, connectors, and condoms? eBOS innovations seen at RE+ 2025

The RE+ conference is a great time to see what’s new in solar and ESS, and to hear compelling pitches on what’s next. But in 2025, I keep thinking about all that is going wrong that shouldn’t be going wrong. As I argued in my Editor’s Note in the Q3 issue of Solar Builder the biggest crisis in solar right now is quality control.

Top of mind for me right now are issues related to wiring and PV connectors — often the cheapest components in a system — which remain the most common area of system failure in commercial and utility-scale solar. According to HelioVolta, 45% of the sites they inspected had major connector issues requiring urgent maintenance. These are risks that can lead to actual fires atop commercial rooftops. HelioVolta published subsequent data regarding subpar work they routinely see throughout solar.

The industry must do better in these basic areas. The good news is, help is on the way.

Create Energy’s PV connector ‘condom’

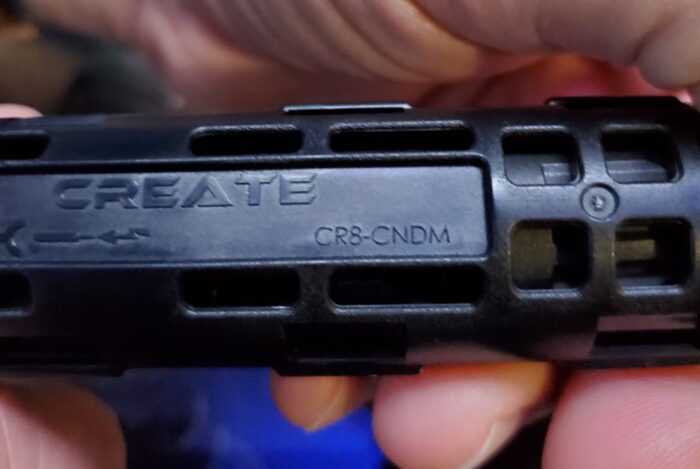

“I call it the Create Condom,” says Dean Solon, founder of Create Energy, handing me one of several new Create Energy products (more on the others later). This is a new solution to a common problem related to the misuse of PV connectors in the field. And “condom” isn’t just another Dean analogy, CR8-CNDM is literally the part number.

The issue: PV connectors are often being put in a position on a solar tracker, either right at installation or over time after zip ties fall off, to handle too much movement and torque. On a tracker, “you’re coming off a 180-degree bend and this whole thing is swinging 120, 130 degrees every day.”

“They’re not made to rotate and spin around unconstrained,” Solon says, twisting around a demo of a PV connection. “You’re asking a very sophisticated electrical joint to do its job, and then, because of the stupidity of the installations, you now ask that same electrical connection that could be moving 50 amps through it to now be a torque transmitter. It’s not a torque converter. This connector would have to be five times the size to hinder that kind of pressure and torque.”

He compares it to a paper clip – twist it around a few times, and its fine, but keep on doing it and eventually it snaps. Not a stress it was designed to handle.

Instead, slip this new Create CR8-CNDM over the connection. It’s two half shells. You click it over any type of PV connector and it locks it up, transmitting the torque from the wire across the CR8-CNDM to the other side, to keep the torque load off the electrical joint.

Each side of the CR8-CNDM stays in place with VHB Tape, an adhesive that keeps junction boxes and high-rise windows in place. Click it together and the VHB Tape compresses and fully hardens in about 10 minutes. The piece also has redundant locks in case something fails.

The CR8-CNDM itself is made of a high-tech resin “that approaches aluminum in strength,” Solon says. “The inside of it is glass fiber loaded. It’s the same material as J boxes.

“We’ve been doing advanced cycling on it, where this is being twisted every five seconds, and we’re at about 30 years. That’s accelerated age testing with humidity, temperature, and all that. I’m going for as long as a warranty claim as possible.”

Make no mistake, Create Energy eventually will be manufacturing a next-generation PV connector at its Tennessee manufacturing facility too. But the CR8-CNDM is a nifty fix to key PV connector failure issue seen in utility-scale solar sites.

We have MUCH more to report on Create Energy’s growing Un-Evil Empire coming soon (some of which Solon explained in our previous article on the company). In the mean time, here are the other eBOS innovations and nifty product updates that stood out at RE+ 2025.

CAB Solar grows line with agrivoltaics in mind

Choosing the right equipment for an agrivoltaics project is critical. Those early procurement decisions will affect both project installation costs and future O&M expenses. CAB Solar has developed a patent protected 3D locking arm for its cable hangers that is quick and easy to install and will keep cables and wires secure for the life of the project, which also makes the habitat safer for animals.

“Our agrivoltaics solution was developed with farmers and livestock in mind,” stated John Giffin, an Engineer and Solar Project Developer for CAB Solar. “The 3D locking arm allows our hangers to withstand the impact of livestock, keeping electric cables secure, and eliminating O&M costs of re-installing dislodged cables. Open cable hangers are very poorly designed for agrivoltaics. Animals will knock the cables loose, and owners will continually be faced with ongoing cable replacement labor costs.”

CAB Solar’s Agrivoltaic 3D locking arm was engineered to wrap around messenger wire at three points, making cable hangers immune to livestock contact. The 3D locking arm can be added to any CAB Solar hanger design as an enhancement, ensuring adaptability for diverse project configuration requirements.

Gripple adds capacity to above-ground cable management

Gripple unveiled a new product updates in their growing line of above-ground cable management systems at RE+ 2025. The standout is this higher capacity edition of their previous system. It leverages a robust twin catenary structure that forms a rigid, fence-like support, minimizing sway and reducing sag. The hanger components are engineered from UV-stabilized, glass-filled nylon 66. Remember – 2 foot spans are not code, it’s just generally what a cable management system can handle. Gripple’s system however has a higher load rating that allows for wider spans between hangers, which can mean reduced material costs and labor requirements.

The hangers can also be installed onto the catenary in 5 seconds – no seriously, even I did it – with a simple snap fix mechanism that prevents any lateral movement. You just toss ’em in there. Gripple says its time trials show had up to 100 ft. of 750kcmil cable installed per minute.

The system accommodates up to 24 runs of 1000kcmil cable, handling high-capacity requirements with ease while avoiding potential derating through proper cable separation.

AWM adds a bonded Bonsai hanger

Affordable Wire Management (AWM) used the RE+ 2025 stage to launch a suite of new cable management products aimed at solving long-standing pain points in utility-scale PV and energy storage. The releases include updated hangers with higher safety standards, a redesigned pile foundation, and a new strap to finally replace plastic zip ties in solar fields. You can read about them all here. For this roundup I wanted to highlight the Bonded Bonsai.

AWM’s Bonded Bonsai hanger builds on its existing Bonsai line with a secure, electrically bonded design that prevents slippage or detachment over decades of use. Offered in multiple formats for bifacial and thin-film modules, the all-metal hanger eliminates long-term maintenance risks while meeting rigorous bonding requirements that go beyond current certifications. The tool-free installation allows one-handed assembly in the field.

“This new offering is rated for electrical bonding standards, which has long been sought after by the industry,” said Scott Rand, CEO and co-founder of AWM.

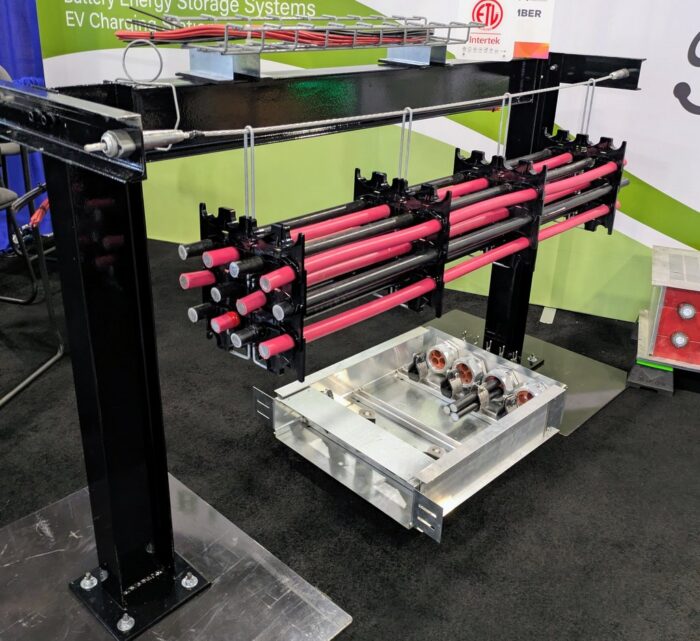

SnakeTray cable management for solar + BESS + EV Charging

Snake Tray continues to spread its wings (er, spread its jaws?) in the solar and energy storage space. Snake Tray has been manufacturing in the United States since its inception in 1996, with a keep focus on avoiding cable deration in above-ground and rooftop solar/PV, battery energy storage, and EV charging installations.

Solar Snake Max is the flagship line, offering a trenchless, free-air cable system for cables up to 1250 Kcmil. It maintains NEC 310.15-compliant cable separation delivering up to 30 watt-hours per meter more energy. Snap-together components allow for fast installation without cable derating.

As you can see above, the system easily adapts to various installation types and is available in both dual or single messenger wire and hard rail configurations. The same principles hold true in the Solar Snake Max for Battery Energy Storage Systems. A variety of cable management solutions are available for interconnecting the batteries to the inverters, solar farms and utility grids. LV and MV systems are also available. All products are designed to install quickly while properly managing the cables.

Southwire rejuvenates 75-year-old business

Southwire is celebrating its 75th year in the cable industry and was eager to share their story at RE+ 2025. With all of our focus on “repowering” and general operations and maintenance work lately, Southwire’s Siloxane cable rejuvenation methods stands out for restoring a cable’s dielectric strength instead of doing a full cable replacement, which is costly, labor-intensive, and may be environmentally disruptive.

“Cable rejuvenation can extend the life of a cable by up to 40+ years and restore it to a better-than-new condition at roughly one-third the cost of replacement,” says Wayne J. Chatterton, PhD, Services Solutions Sales Vice President at Southwire. “Rejuvenation is also environmentally friendly, reducing landscape disruption while mitigating approximately 660K metric tons of CO2. Rejuvenating a 350-foot cable is roughly the equivalent of driving a typical car 5.9 miles, compared to over 3,000 miles for a full replacement.”

Southwire’s Speed Services team also has new tracking system to better manage and use every bit of cable on a steel reel. As you pull cable on one of their steel reel’s, their system will keep track—giving you insight into how much is left in each reel and drastically reducing scrap, which has historically been a huge problem. The Southwire team estimates the service pays for itself with just a 4% reduction in scrap. Better news? Reports from customers who have used the system thus far report a 40% to 50% reduction in scrap. In 2026, Southwire hopes to bring this system to wooden reels as well.

Stäubli preps for 2 kV connectors

As mentioned earlier, dynamic-loading mistakes on single-axis trackers are now surfacing as one of the most common PV connector failure modes. Grayson Maurer, Head of Renewable Energy Services North America for Stäubli, explained to me: Connectors placed in moving sections of trackers are being forced to absorb mechanical loads they were never designed for, leading to premature performance and safety degradation. Stäubli says the fix is less about exotic new hardware than about integration discipline: keeping connectors out of dynamic zones, following NEC strand requirements, and applying correct crimp , torque procedures, and general assembly procedures.

But innovation is still coming for PV connectors, too. To address the market’s march toward higher-voltage plants, Stäubli has released an MC4 variant rated for 2 kV systems, alongside a high-power trunk/bus connector for splices and central inverter tie-ins. Both are designed with assembly quality in mind, especially around aluminum terminations.

Weidmuller USA DC combiners with string monitoring

Weidmuller USA had two product releases at RE+ 20205: 1) a new PV Connectors up to 1500 V that is UL approved and designed to work well with their PV DC Combiner Boxes, and 2) DC Combiner Boxes with real-time string monitoring. Yes, solar farm operators can either buy string monitoring as part of a new box or they can do an easy retrofit and add string monitoring to existing boxes. Weidmuller offers a 5-year warranty on those combiner doxes, and they are assembled in USA.

Comments are closed here.