U.S. battery supply boost: SolarEdge shipping from Salt Lake City, LG expands in Michigan

Two key brands in the battery energy storage space in the U.S. announced production milestones at new facilities this week. Let’s take a look!

SolarEdge Salt Lake, now shipping

SolarEdge Technologies has begun shipping U.S.-made residential energy storage products out of its new manufacturing site in Salt Lake City, Utah, which began producing the SolarEdge Home Battery (USA Edition) in Q1 of this year. The Utah site joins other SolarEdge production sites in Florida and Texas, and collectively contributes to more than 2,000 manufacturing jobs tied to the company’s U.S. operations. With the Utah launch, SolarEdge says its full residential lineup of inverters, optimizers and batteries is now produced on American soil.

“In Utah, we are eager to be a part of our nation’s energy solutions,” said U.S. Representative Celeste Maloy (R-Utah-2), who visited the site. “It’s time to build again in America, and this new manufacturing of battery storage solutions right here in Utah’s 2nd Congressional district is evidence that our state is leading the charge.”

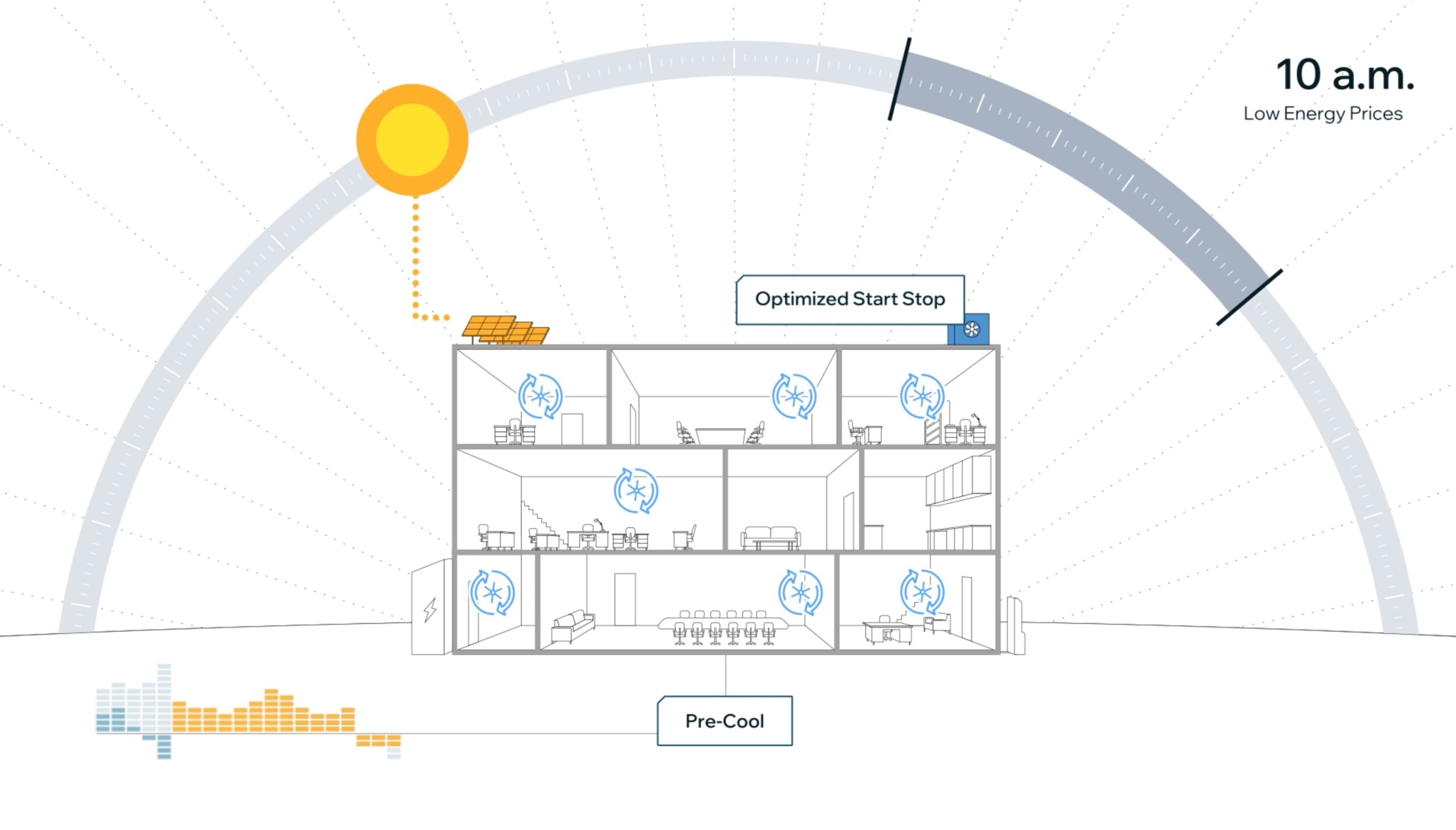

The SolarEdge Home Battery integrates with the company’s optimized inverter architecture and includes a dedicated SKU to simplify domestic content tracking. It is designed for both new solar + storage systems and retrofit applications, and can support load shifting to avoid peak utility rates.

“This expansion not only supports our growth objectives, but reinforces our promise to customers: reliable, high-quality technology with shorter lead times and greater supply chain stability,” said Marty Rogers, General Manager at SolarEdge. “The American energy tax credits have enabled the company to onshore its manufacturing and add to the critical energy infrastructure needed to meet growing U.S. energy demand.”

LG expands into grid-scale battery production in Michigan

LG Energy Solution hosted media this week to promote its expanded battery production in Holland, Michigan, a $1.4 billion investment to go beyond just EV batteries and into grid-scale ESS. At full capacity, the new lines will produce 16.5 GWh of LFP cells per year.

The cell manufacturing is happening as we speak, with module assembly on the way later in the summer. From there, the modules will head to LG’s Arizona facilities to be integrated as a full LG energy storage system. That shipping to Arizona is only temporary, until LG opens an assembly facility in Chicago.

LG is also establishing Green Metals Battery Innovations, LLC, a joint venture company with Toyota Tsusho Corporation, to focused on battery recycling in the U.S. (pictured above). The two partners decided to construct and operate a pre-processing plant in Winston-Salem, North Carolina. The new plant will handle pre-processing operations to extract black mass which contains valuable raw metals such as nickel, cobalt, and lithium, by dismantling and shredding battery production scrap. In the initial stage of the joint venture’s operation, LG Energy Solution will supply scrap generated during the production of EV batteries for Toyota Motor.

Comments are closed here.