Korean university researchers find breakthrough for solar cell limitation

Researchers from Chonnam National University in Gwangju, South Korea have announced an innovation in solar cell technology, with hopes of improving performance in tin monosulfide (SnS) solar cell products.

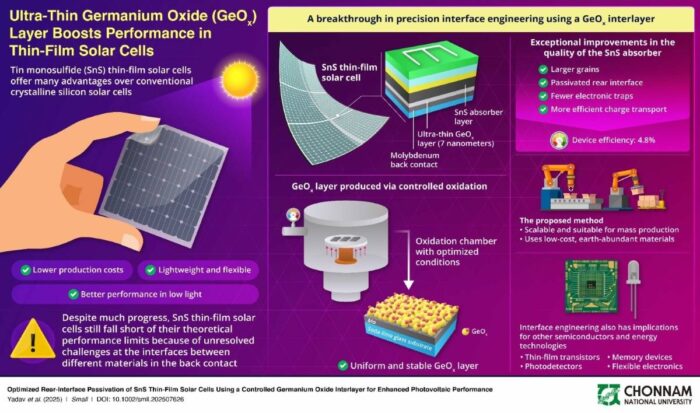

Led by the university’s Prof. Jaeyeong Heo and Dr. Rahul Kumar Yadav, the team has made a “substantial breakthrough” in thin-film solar cell design. Published Sept. 19 in the nanotechnology journal Small, the group’s most recent study showcases a possible mitigation of long-standing issues in cell technology by inserting a thin layer of germanium oxide between the molybdenum back contact and the SnS absorber layer.

“Despite its nanoscale thickness, this interlayer addresses several long-standing challenges at once,” says Prof. Heo. “It suppresses harmful deep-level defects, blocks unwanted sodium diffusion, and prevents the formation of resistive molybdenum disulfide phases during high-temperature fabrication.”

The implementation of this added seven-nanometer thick interlayer gave a “substantial boost” to standard devices, accounting for more a full percentage point jump from 3.71% to 4.81% in power conversion efficiency. The geranium oxide layers “effectively suppress interface states” in semiconductor devices, according to the study, with 4.81% ranking as one of the highest efficiency levels ever reported for SnS solar cells produced using vapor deposition methods.

In addition to theoretically providing optimal electronic and optimal conditions for solar harvesting, SnS materials already align with the Sustainable Development Goals implemented by the United Nations in 2015. However, SnS material tests have consistently fallen short of expectation due to defects and unwanted reactions. If able to mitigate these issues, the research team’s innovation could allow for widespread adoption of SnS materials for thin-film solar cells.

Scalable effectiveness across industries

Chonnam National University representatives said the layer negates quality control issues that have plagued tin monosulfide-based solar products, including unwanted rear contact interface reactions.

The combined effects of the material interlayers not only mitigate common issues with SnS projects, the university says, but also “dramatically improve” the SnS absorber itself. The collegiate research team claims their breakthrough could lead to larger and more uniform grains, enabling enhanced charge transport and significantly reducing electricity losses.

These material buffer layers, including the geranium oxide layer used for this project, present scalable and industry-friendly solutions across several applications including metal and semiconductor interfaces and thermoelectric devices, the school says.

“Across all these applications, mastering the metal/semiconductor interface remains central to advancing next-generation devices,” says Prof. Heo. “We believe that this work will open new avenues for research, contributing to the development of advanced solar cells and other key technologies.”