Underperformance case study: Assessing module power loss using electroluminescence imaging

When solar projects have underperformance issues, deploying the correct field service solution is critical in addressing the problem as quickly as possible. Electroluminescence (EL) imaging can reveal the full extent of PV module degradation or damage – even when the causes of that degradation or the damage cannot be seen by the eye and cannot be detected by infrared/thermal imaging.

In a recent case, PVEL was contracted to a site experiencing severe underperformance and module discoloration to perform a visual inspection and EL imaging on a sample of modules. The results of the imaging and analysis are promising for the ability to correlate EL images to power loss.

Module defect

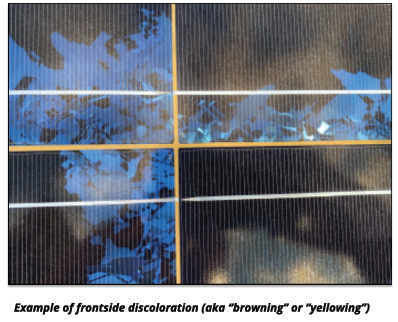

The site owner contacted PVEL due to the site performing well below expectations, with a large number of modules exhibiting concerning levels of discoloration.

During the onsite inspection, PVEL completed EL imaging on a sample of modules and observed three primary patterns in the EL images:

- Darkening near outer edges of the cells

- Darkening between the cell’s conductor ribbons

- Darkening near the cell’s conductor ribbons, with light areas between the cell’s conductor ribbons

For Pattern #3, having higher EL intensity in between the cell busbars versus adjacent to the cell busbars is likely caused by finger metallization near the busbar losing contact with the silicon due to corrosion. This would prevent current from flowing through the cell as intended, with some areas of the cell being isolated from the circuit. It is likely that decomposition of the EVA encapsulant produces acetic acid that causes both the browning and metallization corrosion.

EL image and power loss correlation

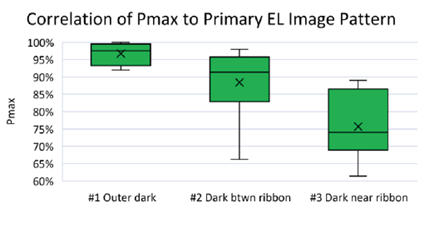

The site owner provided in-field module-level IV curve results for the modules that PVEL inspected. The amount of power degradation measured in the IV curves was compared to the different patterns observed in the EL images, and a correlation between the two datasets emerged.

Using image processing tools, PVEL assigned each image a ‘degradation indicator’ based on the within-cell EL intensity variability. Pattern #1 images had the lowest degradation indicator, pattern #2 images had a higher degradation indicator, and pattern #3 had the highest degradation indicator. Plotting the degradation indicator against the measured power degradation revealed an approximately linear correlation between the two.

In establishing a consistent pattern between EL image signatures and poorly performing modules, PVEL helped the project owner assess module health without performing time-consuming widespread single-module IV curve traces.

In this specific case, PVEL found that correlating EL image results to module power loss is possible for high levels of corrosion. This correlation demonstrates it is possible to estimate power loss due to corrosion for the entire site using an EL imaging campaign. Completing site-level EL imaging via drone EL technology would provide the site owner with a cost-effective categorization of all modules to properly size their power loss warranty claim.

EL imaging advances expedite insurance and warranty claims

To diagnose problems and get sites back online as soon as possible, the downstream solar industry can take advantage of the latest technologies for quickly assessing module damage Until now, the ability to complete EL imaging on large arrays was limited by the number of technicians and cameras that could be deployed on the ground. However, imaging large arrays using aerial drone EL technology is now possible. With drone EL, PVEL can image in one week what would traditionally take a month or more to EL image on foot.

While it’s not always possible to correlate EL images to specific power loss values, EL imaging is a powerful tool for site owners throughout the project lifecycle, including for pre-installation module acceptance, post-installation site acceptance, diagnosing underperformance and damage assessment following extreme weather events.

Todd Karin, is VP of Technical Operations at PVEL

Comments are closed here.