LONGi debuts Hi-MO N-type bifacial module, Lifecycle Quality program at SNEC 2021

The 15th International Photovoltaic Electricity Generation and Smart Energy Conference & Exhibition (SNEC 2021) opened on June 3 in Shanghai, China. Here, LONGi unveiled its Hi-MO N – the first bifacial module with N-type TOPCon cells – touted some record-breaking efficiency numbers and debuted a new “Lifecycle Quality” program.

Meet the H-MO N

Hi-MO N maintains the 182mm cell and 72c module size and adopts LONGi’s proprietary HPC technique based on N-type TOPCon (High Performance Cell with Hybrid Passivated Contact). The conversion efficiency is up to 22.3% and power reaches 570W in mass production. Designed for utility-scale PV power plants, Hi-MO N is expected to be a flagship product. Hi-MO N can achieve higher bifacial gain, better temperature coefficient and low irradiance performance, lower working temperature, better LID and PID performance. Energy yield is 2-3% higher than that of mainstream P-type bifacial modules.

LONGi has a commitment to monocrystalline silicon technology in broad applications of PERC technology spanning P-type bifacial technology to M6 and M10 wafer standards. In tandem with “Zero” cell damage and LONGi’s proprietary smart soldering technology, Hi MO N is PID-free under irradiance. The initial year degradation is under 1% and linear degradation is under 0.4% (Degradation of similar mainstream products is around 2% in its initial year, and linear degradation is approximately 0.45% per year). Calculated on a 30-year lifecycle, the conversion efficiency of Hi-MO N modules will be 2.45% higher than that of other mainstream products in the market.

In addition to high energy yield and low light induced degradation, Hi-MO N also shows its value in reducing BOS costs with its higher module efficiency. The 182mm-size module can minimize costs associated with racking, cable, inverter and labor. Its high conversion efficiency of 22.3% can enhance installed capacity by over 3.5% in areas of limited space and reduce BOS costs as well as costs of AC equipment and operations and maintenance throughout the life cycle of the power plants.

With the release of Hi-MO N, LONGi’s portfolio now includes the “Hi-MO N”, “Hi-MO 5” and “Hi-MO 4” product families: Hi-MO 4 is suited in mountainous regions and areas where handling of modules can be difficult. Hi-MO 5 is the hit product for ultra-large power plants. Hi-MO N is most suited in applications on surfaces with high reflections, high temperature, limited land and high labor costs.

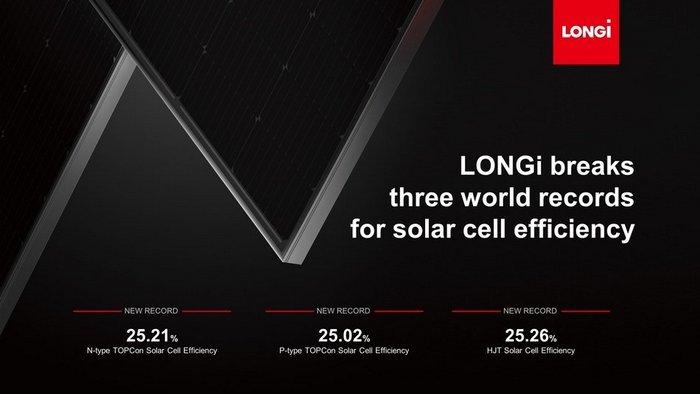

Efficiency records

LONGi has set new cell efficiency records for N- and P-type TOPcon and HJT. The company announced in April its record of 25.09% for N-Type TOPCon solar cell efficiency and, one month later, testing at the Institute for Solar Energy Research (ISFH) in Hamelin, Germany, has confirmed that the conversion efficiency of N-type monocrystalline bifacial TOPCon solar cells developed at LONGi’s Cell R&D Center has now reached 25.21%.

The Cell R&D Center has also achieved an innovative breakthrough in high-efficiency P-type monocrystalline solar cell product technology. Again tested by ISFH (Calibration Mark: 001592), the efficiency of a commercial size P-type monocrystalline bifacial TOPCon solar cell exceeded 25% for the first time, setting a world record of 25.02% in the process.

ISFH has also been able to confirm that the conversion efficiency of a commercial size monocrystalline HJT solar cell produced by LONGi’s New Technology R&D Centre reached a record of 25.26%, additionally placing the company at the forefront of HJT related technology.

Lifecycle Quality

Lastly, LONGi released a “Lifecycle Quality” standard at SNEC 2021 to help ensure its panels perform reliably throughout their lifespan. Customers will be able to access to the quality guarantee and reliable services throughout the lifecycle of their PV power plants.

In terms of technical standards, LONGi has multi-dimension technical benchmarking. On managerial standards, LONGi’s standard BOM and reliability monitoring will cover the entire lifecycle management of its products. As part of this LONGi, emphasized its testing, noting its

- maximum wind speed of 60m/s has been tested on LONGi modules, equivalent to a Category 17 hurricane.

- In the hail test, LONGi enlarged the test size of the pallets to more than 35mm to validate their reliability on these conditions.

During the design stage of PV power plants, LONGi can offer customers high-efficiency products that can be adapted to various condition and provide a comprehensive analysis of the optimal module selection for different applications.

When the power plants enter the construction phase, LONGi’s global module production capacity of more than 50 GW can eliminate customer concerns regarding product delivery. In addition, LONGi’s product quality standard system will fully guarantee the reliability of the product for efficient and stable electricity generation.

In the operation phase of the power plants, customers shift their focus to product quality assurance, stable income stream from the electricity generation, system O&M and power plant optimization. Here, LONGi will rely on its with 30-year warranty.

Comments are closed here.