Bila Solar partners with Origami Solar for 550W steel-framed, U.S.-made solar module

Indianapolis-based manufacturer will pair U.S.-made steel frames with U.S.-made solar cells, offering developers a stronger module and clearer path to the ITC bonus adder

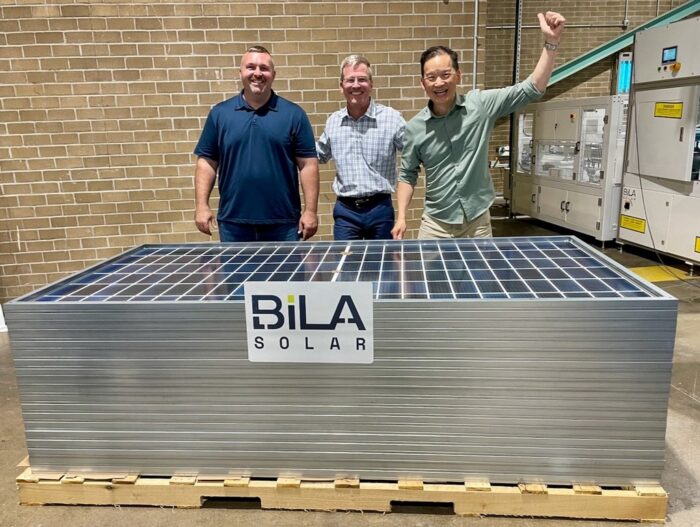

Bila Solar, the Indiana-based solar manufacturer best known for its lightweight polymer modules, is teaming with Origami Solar to bring a steel-framed 550W dual-glass module series to market. The partnership, announced ahead of RE+ in Las Vegas, makes Bila one of the first U.S. panel makers to commercialize Origami’s domestically produced steel frames as an option for solar developers.

Deliveries of the new series are slated for Q2 2026, with both companies showcasing the product on the RE+ show floor this September.

Why steel matters for solar frames

Solar module frames are one of the most overlooked supply chain bottlenecks. Nearly all aluminum frames are sourced from China and Southeast Asia, and the industry has not meaningfully diversified that pipeline in two decades. Origami Solar, winner of the DOE’s 2022 American-Made Solar Prize, has been working to flip that dynamic with a switch to steel.

Steel is not only cheaper than domestic aluminum, but it is also stronger, more recyclable, and supported by a mature U.S. manufacturing base. Origami recently commissioned an automated frame production line in Arkansas with partners Priefert Steel and DAC Robotics, and it has secured a U.S. supply chain of fabricators in Ohio, Texas, and beyond. The company says frames can be shipped to module makers in as little as one to two days, cutting out trans-Pacific shipping risk and embodied carbon.

“America has one of the world’s strongest steel industries,” Origami CEO Gregg Patterson said in previous Solar Builder reporting. “There is simply no reason for the solar industry to accept the enormous risk that comes with imported aluminum frames.”

Bila Solar’s evolving portfolio

For Bila, the Origami partnership builds on its push to diversify beyond its flagship lightweight polymer modules. Those panels, first shown at RE+ 2023, weigh just 17 pounds (0.6 lbs per sq. ft.) and use a structural adhesive mounting method designed for rooftops that can’t support standard arrays. Bila also manufactures a variant with a fiberglass backrail for clamp-based racking systems.

In 2024, the company began producing conventional dual-glass 550W modules in its 157,000-square-foot Indianapolis factory — the first large-scale solar panel facility in Central Indiana — using U.S.-made solar cells sourced from ES Foundry. That addition allowed Bila solar modules to qualify for the 10% domestic content adder under the federal Investment Tax Credit (ITC).

The Origami partnership takes that value proposition a step further. By pairing ES Foundry cells with Origami’s steel frames, Bila’s new 550W line offers an even higher level of domestic content, stronger resilience against tariff volatility, and increased attractiveness for developers and financiers seeking predictable project economics.

“This partnership unites the future of renewable energy with America’s core manufacturing industry,” said Mick McDaniel, vice president and general manager of Bila Solar. “By integrating Origami’s innovative and remarkably stronger steel frames and pairing them with U.S.-manufactured solar cells, we not only offer a stronger, more reliable module but also provide customers with increased domestic content to facilitate access to the 10% domestic content bonus adder.”

Supply chain resilience as a selling point

Global module pricing remains in flux, with import prices rising 0.4% in July alone. Tariffs and shipping uncertainty have only added risk for U.S. developers. Against this backdrop, products like Bila’s new steel-framed series stand out as hedges against volatility.

Origami’s frames offer not only structural advantages but also a 90% reduction in embodied carbon compared to aluminum frames, making them a lower-emission option for developers pursuing ESG goals. Bila’s ability to combine that with U.S.-made solar cells and domestic assembly positions its new line as a high-content product with clear financing benefits.

“Our goal with Origami from the start was to partner with leading manufacturers like Bila Solar to deliver products that push the solar industry towards stronger and more reliable system performance, support U.S. jobs and national energy security, and ensure American innovation remains at the forefront of the renewable energy transition,” Patterson said.

Great to see Bila Solar and Origami Solar pushing the U.S. manufacturing envelope with steel-framed 550 W modules — this kind of domestic supply chain innovation is exactly what the solar industry needs.

At OnePlaceSolar, we’ve been closely following these developments, and we’re excited by the possibilities:

A higher domestic content level means stronger eligibility for ITC bonus adders — a win for project economics.

The shift from aluminum to steel frames could reduce supply chain risks, lowering lead times and cost volatility.

For installations with demanding structural requirements (e.g. rooftop or elevated sites), stronger frames open up new use cases.

Kudos to Bila and Origami for leading on this front. We look forward to seeing field performance, durability data, and how these modules perform in real deployments.

Keep pushing the boundaries — the more resilient and domestically rooted our solar ecosystem is, the better for everyone.

— Team OnePlaceSolar.com