Space Savers

Flat rooftops have many obstacles — lights, ducts, vents and more. An all-inclusive one panel mounting system can decrease the need for tricky design layouts.

Ole Miss may be nationally known for its football, but it’s no stranger to the green campus movement that has swept across America as universities look at new ways to cut spending on energy and achieve sustainability goals. The university already has six LEED-certified buildings on campus, and now its Center for Manufacturing Excellence is also home to the state’s largest rooftop solar installation.

The 108.5-kW rooftop system was installed in January 2012 by Joule Energy, a New Orleans-based solar integration company. The project, funded by the Mississippi Development Authority with matching funds from the university, consists of 392 Suniva 245-W modules and 39 SunPower 320-W modules distributed across three campus buildings. It features three inverter technologies, including a central inverter, micro-inverter array and two hybrid string inverters with optimizers. The mounting system used for the panels — the Renusol CS60 — brings the latest in American technology and innovation to the installation.

The 108.5-kW rooftop system was installed in January 2012 by Joule Energy, a New Orleans-based solar integration company. The project, funded by the Mississippi Development Authority with matching funds from the university, consists of 392 Suniva 245-W modules and 39 SunPower 320-W modules distributed across three campus buildings. It features three inverter technologies, including a central inverter, micro-inverter array and two hybrid string inverters with optimizers. The mounting system used for the panels — the Renusol CS60 — brings the latest in American technology and innovation to the installation.

“With the Renusol CS60, a more flexible layout is possible, and we were able to make changes quickly, without delaying the project waiting for parts or adding new labor costs to the job,” says Julian Thomas, co-founder of Joule Energy.

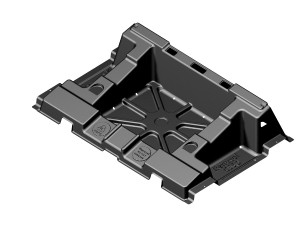

The Renusol CS60 is the first-ever “one unit per one PV panel” mounting system and is made from 100 percent recycled high molecular weight polyethylene (HMWPE), commonly used in truck bed liners, portable restrooms and automotive fuel tanks. By using this plastic, the Renusol CS60 is lightweight, provides excellent UV resistance and is not electrically conductive. The pre-molded HMWPE mounting system is universal and able to fit most panels, making it ideal for the Ole Miss installation using both Suniva and SunPower modules. The system can change how solar arrays are deployed on flat rooftops in America by eliminating the layout restrictions inherent to traditional, rigid aluminum racking rails.

“The Renusol CS60 takes the guesswork out of engineering panel layout configurations,” says Renusol CEO Bart Leusink. “The one-mounting-unit-per-each-panel design means that individual panels can be placed to meet different wind force and weight load conditions across a rooftop.”

Manufactured in the Midwest, the Renusol CS60 offers several solutions developed specifically for the U.S. solar market. The pre-molded unit has fewer and lighter parts, which means a less labor-intensive and more profitable installation and little or no maintenance. The units were also designed with the specific shape and the material strength needed to withstand the wide range of climatic conditions (extreme temperatures, ice, snow) and other natural forces that exist across the United States. The mounting system incorporates recent American-based boundary layer wind tunnel testing in accordance with ASCE 7-05, showing how wind forces vary across a roof. With this new knowledge, the flexible rooftop panel placement made possible with the Renusol CS60 allows for more accurate ballast loads. The mounting units can be attached directly to the roof where more stability is needed or in parts of the country where high winds and earthquakes are a threat.

With on-site and online energy monitoring capabilities, the entire solar power system at Ole Miss will serve as a hands-on teaching tool for the study of solar within the university’s curriculum, but with an intriguing twist: Professors and students can compare the output of the different solar technologies used in the system and choose options that will reap the most significant energy returns on their investment in solar.

With on-site and online energy monitoring capabilities, the entire solar power system at Ole Miss will serve as a hands-on teaching tool for the study of solar within the university’s curriculum, but with an intriguing twist: Professors and students can compare the output of the different solar technologies used in the system and choose options that will reap the most significant energy returns on their investment in solar.

The system consists of independent configurations of solar technologies that can be monitored independently to see which is working at the most cost-effective rate, factoring in the conditions most affecting the system’s output (ambient temperature, wind speed and irradiance). The monitoring display is located within the building, and the solar array’s production information can also be accessed online.

Comments are closed here.