Review of NEC 2020 code revisions and label changes for solar installers

The new National Electrical Code 2020 (NEC 2020) revision is now the latest installment of changes to Article 690 as well as other solar related articles including, but not limited to 692, 694, 705 and 712. Since the Solar industry is changing so quickly, the code revisions continue to come at a rapid pace as the NEC attempts to “keep up” with a growing and demanding industry. Many solar builders choose to design and label their installations based on the latest code revisions. Taking into account local AHJ requirements, why would any company want to label to the latest NEC revision? The easy answer is safety, but new technologies also play a part.

From a panel perspective, safety is the driving factor for almost all code updates. New industry technologies and new code panel requirements, such as the updated requirement for rapid shutdown, add to the complexity of the code, and many states and jurisdictions can take years to adopt the new changes. Installers who choose to label to the latest updates are ensuring their installations meet all existing code requirements, without ignoring label changes that may be applicable to their existing installed technology. These changes may not yet exist at the local AHJ level, but nonetheless impact safety.

Many installers work with their AHJs to make the new labels available as quickly as possible, allowing them to integrate these changes into existing installations, regardless of the “official” local NEC revision.

Let’s look at some of the reasons to update sooner than later. First, I’ll break down many of the changes to the NEC 2020 into four basic groups: 1) code-making-panel driven, 2) industry driven, 3) editorial driven and 4) overridden by the local AHJ. However, the most important source for code changes can be found in the public comments submitted to the panel during each code cycle.

1. Code-making panel changes

Many times, the code-making panel will examine the industry and work to set objectives. While difficult initially, they are designed to drive manufacturers to a common goal. One example of an evolving code panel requirement relates to rapid shutdown in Article 690.56. Originally adopted for the NEC 2014 code cycle, it has evolved over time. Most recently, for NEC 2020, the following was updated as follows:

690.56 Identification of Power Sources.

- (A) Facilities with Stand-Alone Systems.

- (B) Facilities with Utility Services and Photovoltaic Systems.

- Plaques or directories shall be installed in accordance with 705.10 and 712.10 as required.

EXPLANATION:

- A: Language has been added to recognize the use of plaques and directories in stand-alone systems.

- B: Language has been added to recognize the use of plaques and directories in interconnected DC systems such as DC microgrids. Depending on the system, the installer will select 705.10 or 712.10.

As part of these updates, the panel eliminated one of the rapid shutdown labels found in 690.56(C)(1)(b).

EXPLANATION: 690.12(C)(1) was revised to remove the option for the label, previously listed under 690.56(C)(1)(b), since this label describes a shutdown method that is no longer code compliant in NEC 2020. When rapid shutdown was first published, the panel established a timeline for compliance, which has now passed. Since all installations are now required to have rapid shutdown, this label is no longer needed, and the panel simplified the code by removing the requirement.

In keeping with the spirit and intention of rapid shutdown, the panel also loosened restrictions regarding the marking of DC conduit, which should no longer be energized when a rapid shutdown switch is activated. The new updated code language is shown below:

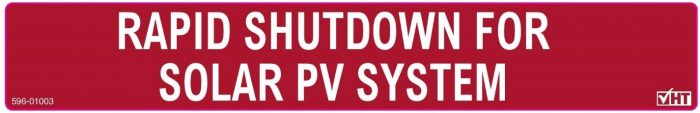

690.56(C)(2) – CHANGED – Rapid Shutdown Initiation Device

A rapid shutdown initiation device shall have a label located on or no more than 1 m (3 ft) from the initiation device that includes the following wording:

The label shall be reflective, with all letters capitalized and having a minimum height of 9.5 mm (3⁄8 in.), in white on red background. The previous label was printed as follows:

EXPLANATION: The terminology “switch” is no longer used as it can apply to many types of initiation devices. The new code also provides clarification on where to place the label. Another important code-driven change addresses the evolving requirements related to marking the DC conduit. Once again, now that rapid shutdown is a requirement, the conduit labels no longer need to be reflective. Also, an additional label option was added to identify a DC conduit as a “SOLAR PV DC CIRCUIT.” The updated code reads as follows:

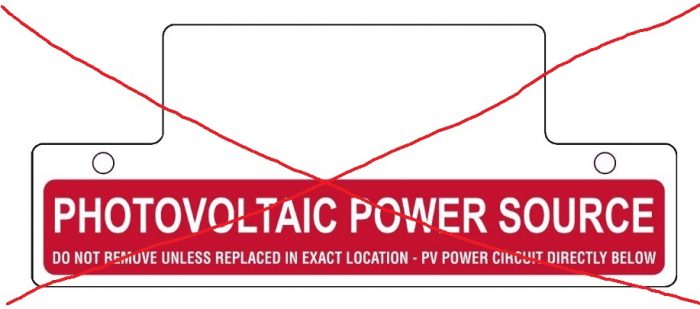

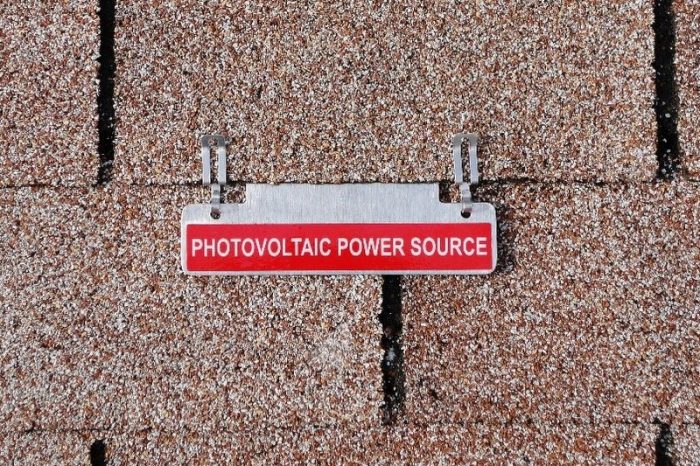

690.31(D)(2)

Unless located and arranged so the purpose is evident, the following wiring methods and enclosures that contain PV system DC circuit conductors shall be marked with the wording PHOTOVOLTAIC POWER SOURCE or SOLAR PV DC CIRCUIT by means of permanently affixed labels or other approved permanent marking: (1) Exposed raceways, cable trays, and other wiring methods; (2) Covers or enclosures of pull boxes and junction boxes; (3) Conduit bodies in which any of the available conduit openings are unused.

The labels or markings shall be visible after installation. All letters shall be capitalized and shall be a minimum height of 9.5 mm (3⁄8 in.) in white on a red background. Labels shall appear on every section of the wiring system that is separated by enclosures, walls, partitions, ceilings, or floors. Spacing between labels or markings, or between a label and a marking, shall not be more than 3 m (10 ft). Labels required by this section shall be suitable for the environment where they are installed.

EXPLANATION: The reflective requirements for rapid shutdown in the NEC 2017 edition were removed in the NEC 2020. This label no longer requires a reflective warning as the DC conductors are no longer dangerous after rapid shutdown. The label now is simply used to identify the DC circuit for maintenance and repair. The word WARNING was removed to shorten the label text and to comply with ANSI Z535.4.

2. Industry-driven changes

Many additional changes to the NEC come from new technology and other innovations in the market. Some examples of industry driven changes include the growing influence of fuel cell systems, including wind electric systems. As a result, article 692.4(B) is a new requirement:

692.4(B) Identification FUEL CELL SYSTEMS – NEW

- (B) Identification of Power Sources. Fuel cell systems shall be identified according to 692.4(B)(1) through (3).

- (1) Interconnected AC Systems. Plaques or directories shall be installed in accordance with 705.10.

- (2) Interconnected DC Microgrid Systems. Plaques or directories shall be installed in accordance with 712.10.

- (3) Stand-Alone Systems. Plaques or directories shall be installed in accordance with 710.10.

EXPLANATION: Three separate sentences were used to describe three different types of systems and related plaques or directories.

694.54 Identification of Power Sources – WIND ELECTRIC SYSTEMS – NEW

Wind turbine systems shall be identified according to 694.54(A) through (B).

- (A) Interconnected AC Systems. Plaques or directories shall be installed in accordance with 705.10.

- (B) DC Microgrid Systems. Plaques or directories shall be installed in accordance with 712.10.

- (C) Stand-Alone Systems. Plaques or directories shall be installed in accordance with 710.10.

EXPLANATION: Three separate sentences were used to describe three different types of systems and related plaques or directories.

Another example of an industry-driven change can be found in the elimination of certain labels. In some cases, we find redundancy or determine a particular label is no longer used in a typical installation. In those cases, we clean up the code by eliminating the label requirement. An example from the new NEC 2020 code:

690.52 – Label Eliminated. The information outlined in 690.52 is required as part of the listing requirement of this equipment. Since this equipment is required to be listed per 690.4(B), there is no option to install a PV AC module without this information being provided on the device by the manufacturer. A reference to AC modules being marked in accordance with their listing has been added to 690.51.

EXPLANATION: The roof no longer needs to be marked to indicate the DC power circuit. This refers to a wiring method that is no longer used. The Fire Service says it must be 10” below decking, so it should no longer be a problem as these wiring methods are not encouraged. In other cases, the information required may be simplified to improve communication as in the changes to the label requirement in article 690.53.

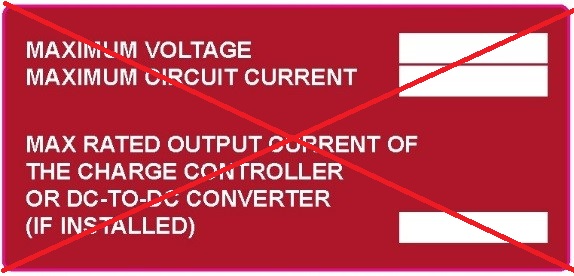

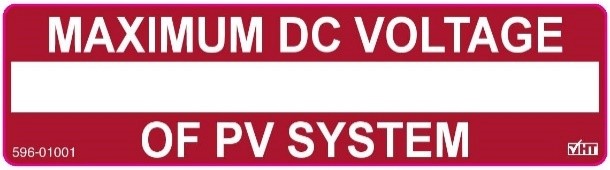

690.53 DC PV Circuits

A permanent, readily visible label indicating the highest maximum DC voltage in a PV system, calculated in accordance with 690.7, shall be provided by the installer at one of the following locations:

- (1) DC PV system disconnecting means

- (2) PV system electronic power conversion equipment

- (3) Distribution equipment associated with the PV system

A single field-applied label indicating the maximum DC voltage must be installed for any PV system with DC circuits. This is required for safety purposes to clearly indicate the maximum voltage to servicing personnel for PPE and tool selection. Since some PV equipment, such as certain inverters, may have multiple DC circuit inputs, the highest value present in the system shall be used on the single label.

EXPLANATION: Values for maximum circuit current have been removed from the label requirements since all equipment will be marked with its rated current through its listing. It is also desirable to remove these values from the required label in order to not inadvertently create conflict or confusion with any other required safety labeling such as may be required in Article 110.

Regardless of whether a change is code driven or industry driven, safety is critical. Waiting years to implement key changes isn’t worth the risk to the typical installer. The safety of their installation is critical, and avoiding a failed inspection reduces operational delays and keeps costs down.

3. Editorial-driven changes

Many other changes address simple things like organizing data in the code by moving articles to locations that make more sense to the requirement. An example can be found below:

New Bipolar PV System Requirements – 690.31(I) is now moved to 690.31(E)

EXPLANATION: The label and code text have not changed, just the location. The label shown below shall be used to clearly mark bipolar photovoltaic systems with a warning notice indicating that disconnecting the grounded conductor(s) (not the neutral) could result in overvoltage of the equipment.

This section of code simply clarifies (for reference grounded bipolar systems) that these bipolar arrays must be separated into two distinct monopolar arrays when the grounded conductor is interrupted, so overvoltage does not occur.

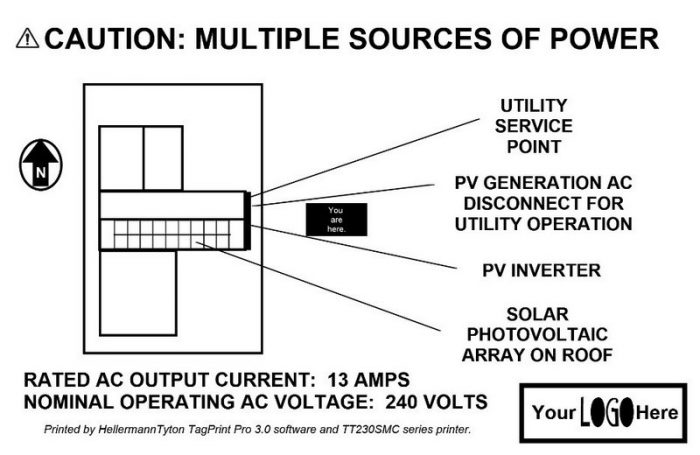

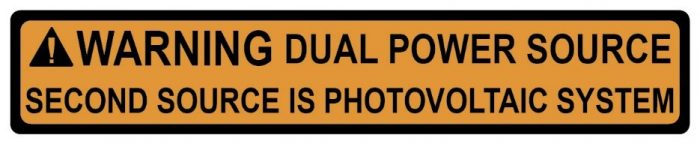

705.10 Identification of Power Sources – UPDATED SECTIONS BOLDED.

A permanent plaque or directory shall be installed at each service equipment location, or at an approved readily visible location. The plaque or directory shall denote the location of each power source disconnecting means for the building or structure and be grouped with other plaques or directories for other on-site sources. The plaque or directory shall be marked with the wording “CAUTION: MULTIPLE SOURCES OF POWER.” Any posted diagrams shall be correctly oriented with respect to the diagram’s location. The marking shall comply with 110.21(B).

Exception: Installations with multiple co-located power production sources shall be permitted to be identified as an entire group. The plaque or directory shall not be required to identify each power source individually.

EXPLANATION: Changes made to this section to align with related changes to identification of power sources in other articles in a continued effort to harmonize all directory requirements for onsite sources under a variety of applications. Changes to allow the user to orient themselves to the building and the disconnecting means. The plaque does not require a diagram; can be just text, i.e., NW corner.

Moved: Was 705.10(B)(3) now 705.10(C)

(C) Marking.

Equipment containing overcurrent devices in circuits supplying power to a busbar or conductor supplied from multiple sources shall be marked to indicate the presence of all sources.

EXPLANATION: Text moved to new location that is more appropriate to the requirement.

Moved: Was 705.12(B)(2)(3)(d) now 705.12(B)(2)(3)(c) Labeling for Power Information

(d) A connection at either end, but not both ends, of a center-fed panelboard in dwellings shall be permitted where the sum of 125 percent of the power source(s) output circuit current and the rating of the overcurrent device protecting the busbar does not exceed 120 percent of the current rating of the busbar.

EXPLANTION: This clarifies that connections can be made at both ends of a center-fed panel, provided the ampacity is not exceeded.

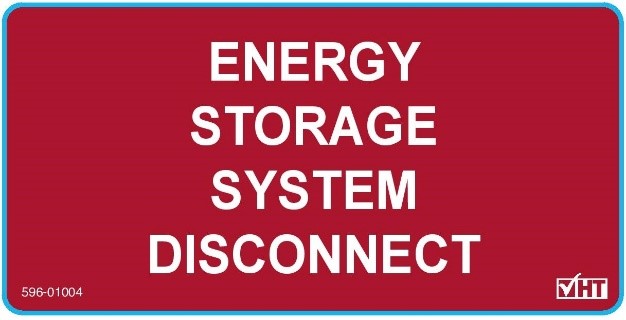

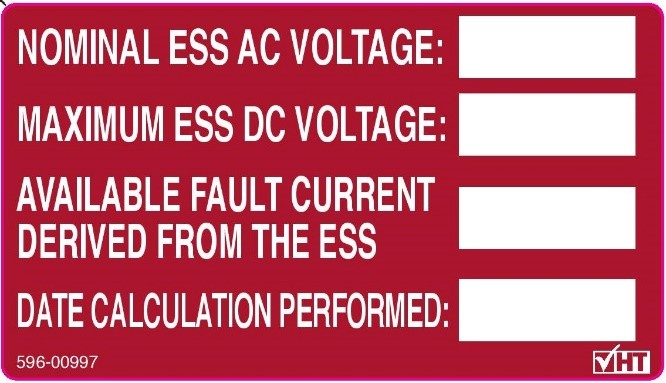

706.15(C) Energy Storage – CHANGED

Installed ESS (Energy Storage Systems). Each ESS disconnecting means shall plainly indicate whether it is in the open (on) or closed (off) position and be permanently marked “ENERGY STORAGE SYSTEM DISCONNECT”

The disconnecting means shall be legibly marked in the field to indicate the following:

- Nominal ESS AC voltage and maximum ESS DC voltage

- Available fault current derived from the ESS

- Data calculation was performed.

Some municipalities require Maximum ESS DC Voltage, so this has been added to the label by HellermannTyton. NOTE: An additional arc-flash label must also be applied with acceptable industry practice.

EXPLANATION: In the NEC 2020 Code, MAXIMUM ESS DC VOLTAGE ADDED. The labeling in 706(D)(1-4) shall not be required if an arc-flash label is applied in accordance with accepted industry practice.

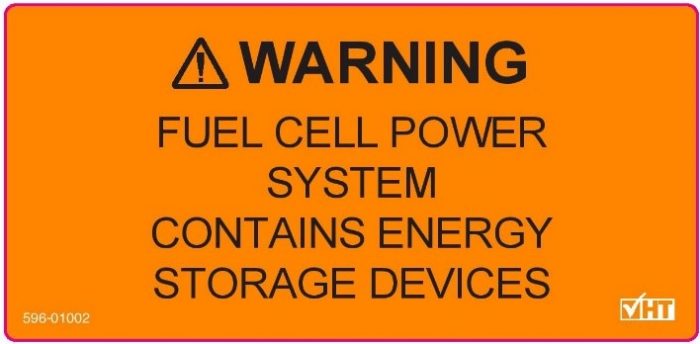

NEC 692.56 Stored Energy

A fuel cell system that stores electrical energy shall require the following warning sign, or equivalent, at the location of the service disconnecting means of the premises:

EXPLANTION: This did not change from NEC 2017 but is associated with the labeling shown above for energy storage systems.

Just like the previous code revision NEC 2014, all other warning and caution labels, unless otherwise specified, should meet the requirements of ANSI Z535.4 – 2011 per the informational note in Article 110.21(B) in the NEC 2014/2017/2020. The ANSI standard requires that Danger, Warning and Caution signs use the standard header colors, header text and safety alert symbol on each label. The ANSI standard requires a heading that is at least 50% taller than the body text. While not required in the NEC 2020, the message text should be at least .12″ tall. If we compare this to OHSA 1910.145 and ANSI Z535, it is specified that signs must be visible at a safe viewing distance from the hazard. They also recommend the use of safety alert symbols, where applicable.

4. Locally-driven requirements

The one caveat that installers must consider are the local regulations. They can and do trump NEC requirements. Some communities mandate the use of an engraved plate, and in those instances the installer must comply. Yet, in most districts, there is no specific definition of what type of marker is required. This gives the installer more variability in selecting a labeling solution.

Again, there is no right or wrong answer on marker selection, provided the installer is meeting the requirements of the AHJ in all instances. The trend we are seeing is that labeling products with specialized features, such as reflectivity, is going away as systems become safer using rapid shutdown techniques.

The market is evolving and, like any other industry during growth, the players will seek to find the best solutions at the lowest cost. The cost of not passing an inspection is just as important as the cost of a marker. As the standards become more defined, additional solutions will become available to the designer, engineer and contractor.

Many adjustments are sure to come as the industry progresses and labeling grows with the changes to become a standard everyone can define and implement now and in the future.

NEC 2020 offers new insights into the dynamics of labeling the PV installation. It includes changes that are code-panel driven, industry driven, edited for editorial content or code harmonization, and yet subject to the local AHJ requirements. The bottom line is that the changes are good and contribute to simplifying and enhancing code requirements as well as overall safety. The market and industry continue to change at a rapid pace and the NEC is working to keep ahead of those changes. Your continued input is critical.

Todd Fries, HellermannTyton’s product category manager – identification, who has long served on Code Making Panel 4 of the NEC.

Comments are closed here.