Railless to Waterproofing

Railless solar mounting and racking systems rely on a direct interface between the module and roof attachment. This low-profile design can improve aesthetics while reducing part counts and installation time.

The Evolving Roof Mounting Market with Quick Mount PV

The roof-mounted solar project has plenty of parameters. A successful installation starts with proper panel location and correct angle to the sun, but that install list will be both long and with limitations. As long as the roof is free of shade and faces south (east and west are good too, but south is optimal), there will be plenty of sunshine for those panels. A contractor needs to compare mechanical build plans to as-built roof conditions. Crews need to check layout specs to confirm dimensions, obstructions and quirky roof features, as well as understand local legislation (like California fire codes).

Of course, the ideal installation also requires the perfect product.

In the solar industry, a project often specifies the product. For instance, many mounting companies focus on specific applications — like metal rooftops or landfill caps — while others focus on different materials — like fiberglass or HDPE.

Railless mounting approaches, which remove long spans of aluminum from the installation process, are becoming more and more popular in the sloped roof market. Railless systems rely on a direct interface between the module and roof attachment. This low-profile design can improve aesthetics while reducing part counts and installation time. Some railless systems even offer integrated grounding and wire management features and are compatible with a variety of roof attachment solutions.

A good example is Quick Mount PV, a Walnut Creek, Calif., manufacturer focused on high-quality waterproof mounting systems; the company also has an interesting addition to the rail-free solar mounting market. The company’s Quick Rack Rail-Free Mounting System integrates the roof mount and the racking together to significantly reduce material handling, installation time and labor costs.

“This patented QRack technology eliminates the need for rails to support the modules and the time intensive step of rail installation on the job — just mounts to modules vs. mounts to rails to modules,” said Anne Wright, vice president of sales for Quick Mount PV. “The Quick Rack system also has UL 2703 certified integrated grounding, eliminating the need for grounding each module. One ground lug per contiguous array.”

The key to railless mounting and racking systems is ease of delivery, ease of installation and a good-looking result. First off, how the equipment and products will be handled and staged is a big element to any project’s success. A contractor needs to identify where delivery trucks should unload, how equipment and materials will be lifted to the roof and where they will be staged for maximum efficiency during installation. By eliminating long rails, products like the Quick Rack can be packaged in small boxes, making the entire mounting system easy to transport, from pulling it out of the warehouse to lugging it up to the rooftop.

“Quick Rack has been used on residences from Massachusetts to Southern California — on roofs with 45-degree slopes to the lower slopes of California homes — in portrait and landscape and even combination configurations,” Wright said.

Once on the roof, the speed and ease of installation is paramount. Quick Rack, for instance, works with standard module frames and requires just a single tool for install. Micro-inverters and optimizers attach to the module frame with simple mounting brackets designed by Quick Mount PV. Wire management is easily achieved by clipping the wires to the module frames. The company says Quick Rack cuts close to 30 percent off installation time compared to rail mounting products. Contractors just need to measure out the roof, put the mounts in and start laying modules.

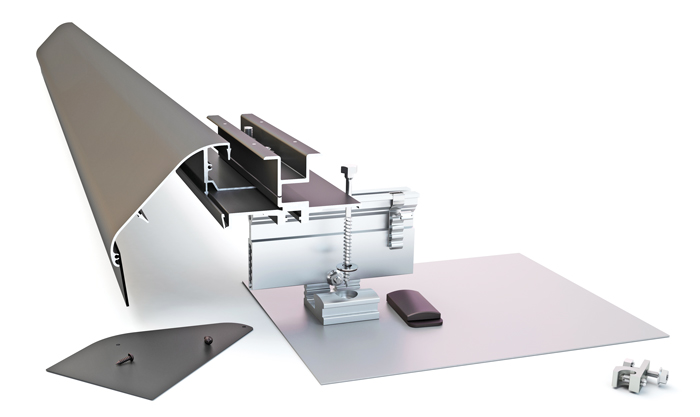

Quick Rack has three parts. The base mount incorporates a pre-assembled, adjustable top slider, the panel clamp attaches the modules to the mounts and a snap-on skirt gives the finished array a clean, distinctive look.

To keep it simple, the product basically has three parts. The base mount incorporates a pre-assembled, adjustable top slider and features Quick Mount PV’s patented Elevated Water Seal for waterproofing. The panel clamp attaches the modules to the mounts and also functions as a self-leveling patented bridge to securely connect the modules together, transforming the module frames into structural components of the array.

Integrated grounding pins eliminate the need to run long copper wires across the roof and require only one grounding lug for the entire array, while a snap-on skirt gives the finished array a clean, distinctive look. If that sounds complicated, the company has created an app to help contractors get it right the first time.

“The Quick Rack Designer is an app-based array designer that allows the installer to design an array and produce permit-ready drawings as well as an engineering report,” Wright said. “Because it is app based and all designs are stored in the cloud, the installer can modify and re-engineer the design on the jobsite with a tablet or phone. Arrays can be designed in landscape, portrait or mixed orientation, and the design software readily accommodates any obstructions on the roof.”

Quick Mount PV certainly isn’t the only manufacturer making railless solar mounting and racking products. Brands from Roof Tech to SolAttach have launched quality railless mounting hardware products, but the folks at Quick Mount PV like to think they standout with their patented technology, warranty (10 years) and their waterproofing focus. Waterproofing penetrations for solar mounting is actually a fairly serious issue. A solar array on a new roof can last 30 years, but long-term waterproofing is a challenge as mounts flex daily due to wind loads and the difference in expansion/contraction of wood roofing vs. the metal PV racking.

Solar waterproofing is a statistical challenge. Solar installations require dozens of penetrations, meaning even a small leak rate can still be a big problem. A small 1 percent leak rate, meaning 1 percent of all roof penetrations, after 10 years equates to 30 to 50 percent of your PV installations leaking, according to Quick Mount PV. Fixing leaks will cost most PV owners more than replacing their inverter.

“We like to think of quality, waterproof mounting systems as cheap insurance,” said Meghan Vincent-Jones, marketing director for Quick Mount PV. “This is not where you want to cut corners. Use high-quality products, get educated about roofing best practices and learn how to install solar mounts properly, and you can rest assured you will not be dealing with a costly roof leak down the road.”

Keith Gribbins is associate publisher of Solar Builder.