Questions facing the lithium-ion battery future

Advanced batteries are the storage system favored by utilities and microgrids. The electric future — including expected dramatic growth in EV adoption — is close. Or is it? This was the big question asked during an April 22 webinar hosted by the US Energy Association.

“This surge forward, driven by environmental concerns and the desire to go green quickly, faces one ominous hurdle: the lithium-ion battery and its precarious supply chain. While electrification of everything is cheered everywhere, there appears to be danger in depending on the lithium-ion battery as none of the principal components are sourced in the United States,” observes the USEA.

The webinar panel discussed various concerns surrounding the topic and were subsequently quizzed by a group of journalists. The following paraphrased comments were among the takeaway highlights of the webinar, organized by topic.

Battery cost and lithium shortage impacts

John Howes, Principal, Redland Energy Group

The question isn’t whether lithium batteries work or not. The question is at what cost. EVs are still less than 5% of the U.S. automobile market, and costs must come down for EVs to gain a significant market share.

Ned Mamula, Economic Geologist and Author

When see the words “lithium shortage,” that is a misnomer; we’ve got plenty of reserves, but we need to let the market system work (with greater regulatory cooperation). We can’t rely solely on imports or recycling. For example, there are proposals before DOE to take the natural lithium content in water from oil and gas sites.

Scott Aaronson, Senior VP, Security and Preparedness.

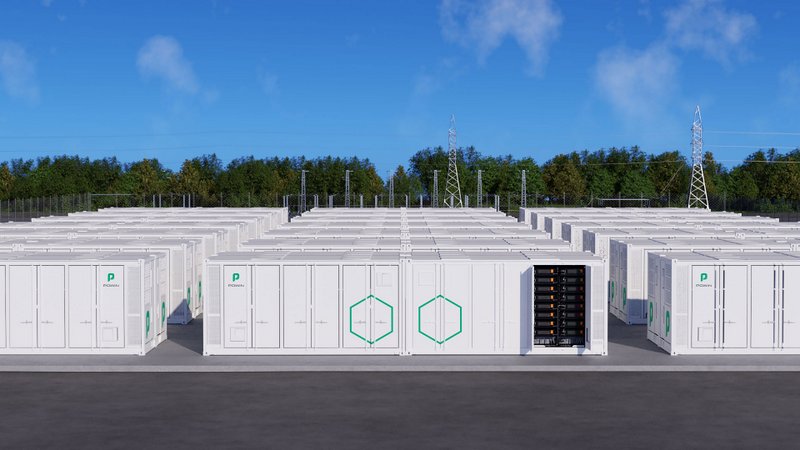

What we’re seeing is lithium scarcity as the mother of invention. A lot of companies are exploring different, alternative approaches to storage, particularly at the grid scale. However, this “shortage” isn’t just about transportation, or renewables on the grid, or the supply chains. We’ve got to look holistically at the entire value chain and develop technologies that will contribute over the coming decades.

Howes: One approach that might be attractive is the facilitation of the replacement of batteries — swapping out at a gas station. There is a company in California (Ample Inc.) that is doing that now, and we may see more.

The prospects of bidirectional EV charging

Aaronson: Two-way EV battery flows are really exciting. But it introduces the smart grid paradox: when you deploy more devices and communications, you absolutely introduce cyber vulnerabilities. None the less, you can increase the reliability of grid battery systems by baking it in, rather than bolting it on after the fact. New technologies that enhance resilience should be treated as the critical infrastructure that they are.

Diversifying lithium-ion sources

Eric Dresselhuys, CEO, ESS Inc

It takes a complex supply chain to build batteries. The minerals are mined in countries where environmental controls and ESG norms (Environmental, Social, and Governance) are not in effect. China buys the mineral rights, ships the ore to China, refines the mineral, then ships it to the United States. We can improve the supply chain process faster than we can improve mining.

Mamula: We import lithium from countries in which there is no accountability. A true environmentalist would say “if we’ve got to mine, let’s do it here where there is regulatory oversight and where production processes are better.”

Dresselhuys: It amounts to a hidden subsidy when lithium mining is done overseas.

Howes: EPRI’s first-class work within the Low Carbon Resources Initiative (LCRI) presents a broad range of options for a low-carbon future.

Lithium-ion substitutes?

Aaronson: Demand is through the roof. Energy companies tend to stockpile. We need to look for redundancy. If lithium is a single point of failure, we need to look at alternatives.

Dresselhuys: Non-lithium-based storage can take much of the pressure off the market growth. We need a massive number of batteries for storage. We need to break out use cases to select the battery chemistry characteristics most valued. We won’t reduce the amount of lithium batteries used in the near term, but we can reduce the rate of growth by using alternative technologies where they are better suited. At ESS, we build iron redox flow batteries using abundant materials that include iron, salt and water, that are 100% recyclable. But these are targeted to the grid, not to EVs or phones.

Howes: We need to look at other elements that can be put into battery storage like iron, lead and copper. There may be greater efficiencies for them. The lead industry is working with Argonne (National Laboratory) at that. DOE says lithium is not the only game in town.

Stephanie Shaw, Technical Executive, EPRI

The cost-benefit analysis of battery chemistry needs to include the life cycle of the material and any potential second life. It is also important to define the environmental and social costs in the analysis.

Llewellyn King, the Creator, Executive Producer & Host of White House Chronicle

Silicon is a crucial (structural) additive to make lithium batteries cheaper and more effect long term. Some manufacturers now use graphite, but if they replace that with silicon, the battery will be lighter and safer.

The evolution of battery recycling

Shaw: Recycling lithium-ion batteries to retain high purity is tricky. Solid state batteries may reduce the complexity of recycling. Sodium or zinc chemistry options also could make recycling easier. As battery capital costs drop, manufacturers will recognize that planned recycling will make them differentiated in the market.

Howes: When we talk about recycling, we should remember that lead is 99% recycled; it’s more of a closed loop.

Shaw: Environmental justice and equity promotion are everywhere now in public dialog; these issues are some of the most complex we face. These concerns will filter down to every level of regulation and implementation. They will impact our lands and our work.

Charles W. Thurston is a contributor to Solar Builder.

Comments are closed here.