Battery storage prices spike as manufacturers react to U.S. tariffs

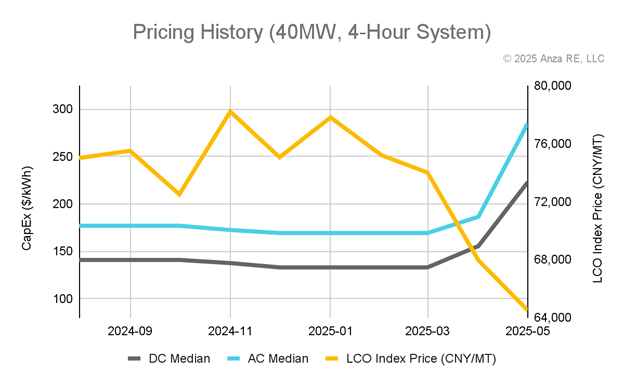

The tariff actions in the United States have caused a sharp increase in battery prices, according to the Q2 Storage Pricing Insights Report from Anza. This battery price spike is “the sharpest single jump in battery energy storage prices” since Anza’s inception in 2021 — a time period that includes post-pandemic supply chain woes.

To recap: A universal 10 percent tariff, a 145 percent total IEEPA tariff rate on China, and Section 301 pushed every manufacturer to pause quoting in early April, according to Anza. Most returned to the market by late April with shorter validity windows.

“The May reprieve cuts the IEEPA China rate to 30% for 90 days beginning May 14 (Section 301 remains in effect), but suppliers continue to protect their margin through contract contingency clauses,” The Q2 Storage Report states.

Anza expects prices to “stay volatile until policy clarity returns.”

Anza battery energy storage analysis

This Anza BESS report analyzes two common project sizes: a 40 MW distributed‑generation project and a 200 MW utility‑scale project, each configured for four hours of duration. All prices come directly from manufacturers through the Anza platform and include the latest tariffs, shipping, and duties.

- All figures are shown on a project CapEx basis for the U.S., covering costs like materials, commissioning, and applicable tariffs.

- Data runs through May 19, 2025, and reflects the 90 day China tariff pause effective beginning May 14, which temporarily lowers the rate on Chinese battery imports.

- AC system prices cover the battery block, Power Conversion System (PCS), and Energy Management System (EMS).

- DC systems cover the battery block only.

Other Market Factors Affecting Energy Storage Prices

From the Q2 Storage Pricing Insights Report from Anza:

Lithium-Carbonate Prices Fall | “Spot lithium‑carbonate indices fell from 77,500 CNY per tonne in February to 64,500 by early May (-17%), reaching their lowest level since 2021. The savings on cell cost could not offset the tariff shock, so delivered system prices still rose.”

Shipping Costs Increase | “Asia-U.S. container production rose sharply due to the tighter vessel supply caused by tariffs. The 90-day tariff reprieve that went into effect on May 14 is expected to increase shipping costs in Q3 2025 as all industries try to bring imports into the US to take advantage of the lower tariffs.”

Preliminary Anode-Material Ruling Under Review | “The International Trade Commission released a preliminary countervailing‑duty decision on Chinese active anode material on May 20, 2025. The base duty of 6.55% may have minimal impact at the DC block level. Still, we are continuing to track this in depth, including the ongoing anti-dumping (AD) investigation and potential implications for affected OEMs.”

State of Storage Heading Into Q3

Anza: “Tariffs eclipsed every cost tailwind this quarter. Falling lithium‑carbonate and incremental efficiency gains could not match the tariff shock, and freight premiums piled on. Compared with January 2025 levels, delivered AC system prices now sit 68% higher in the DG market and 56% higher at utility scale. DC‑only solutions climbed 68% and 69%, respectively. We expect prices to stay volatile until policy clarity returns.”

Comments are closed here.