Case Study: Terrasmart’s flexible 1P tracker speeds experimental success in New York

Utilities across the country are working to integrate intermittent renewables while maintaining resource adequacy, reliability, and resilience. It’s a complex challenge that demands innovation and flexibility.

National Grid, serving 20 million customers in New York, Rhode Island, and Massachusetts, piloted an Active Resource Integration (ARI) program to increase distributed generation (DG) interconnections. The initiative tests how much distributed solar substations can handle without overloading critical equipment, using renewables to better manage peak capacity constraints.

That’s where Terrasmart and Nexamp come in. As a leading community solar developer in the Northeast, Nexamp is advancing clean energy adoption through participation in this groundbreaking program. Because ARI allows National Grid to curtail participating projects when needed to ensure system reliability, developers like Nexamp gain flexibility and a faster interconnection path, bypassing engineering studies that can cost up to $1 million.

For its first ARI project, Nexamp selected Terrasmart’s highly flexible 1P TerraTrak system to match the program’s need for adaptability.

“We trust Terrasmart to design and build a sustainable, reliable, low maintenance tracker system. If we know we are going to lose potentially 2.5% in a year because of the ARI’s curtailment, we don’t wanna lose any additional money in repairs,” said Hugh Jones, project manager for Nexamp.

Allis Hill: A Model of ARI Project Execution

Located 30 minutes east of Syracuse, New York, the 6.4-MW Allis Hill community solar site serves both a large commercial customer and local subscribers. Facing challenging snow, wind, and soil conditions, Nexamp turned to its trusted partner Terrasmart to install ground screw foundations and supply the 1P tracker, while Phoenix Solar handled mechanical and electrical installation.

Ground Screws for Tough Conditions

Terrasmart pioneered ground screw foundations in the U.S. over a decade ago, earning a reputation for reliability in difficult terrain. These foundations mitigate risks from frost heave and shifting soils, ensuring long-term stability through the Northeast’s harsh winters and freeze-thaw cycles.

Terrasmart’s end-to-end approach, spanning precise surveying to proprietary installation equipment, helped accelerate construction. With a small, three-person team, installers exceeded their target of 175 screws per day, averaging 200, each completed in under four minutes.

The efficiency paid off: a 35-day schedule was completed in just under three weeks. Faster installation not only reduced costs but also allowed Nexamp to start generating returns and delivering clean power sooner.

Integrated Systems for Greater Flexibility

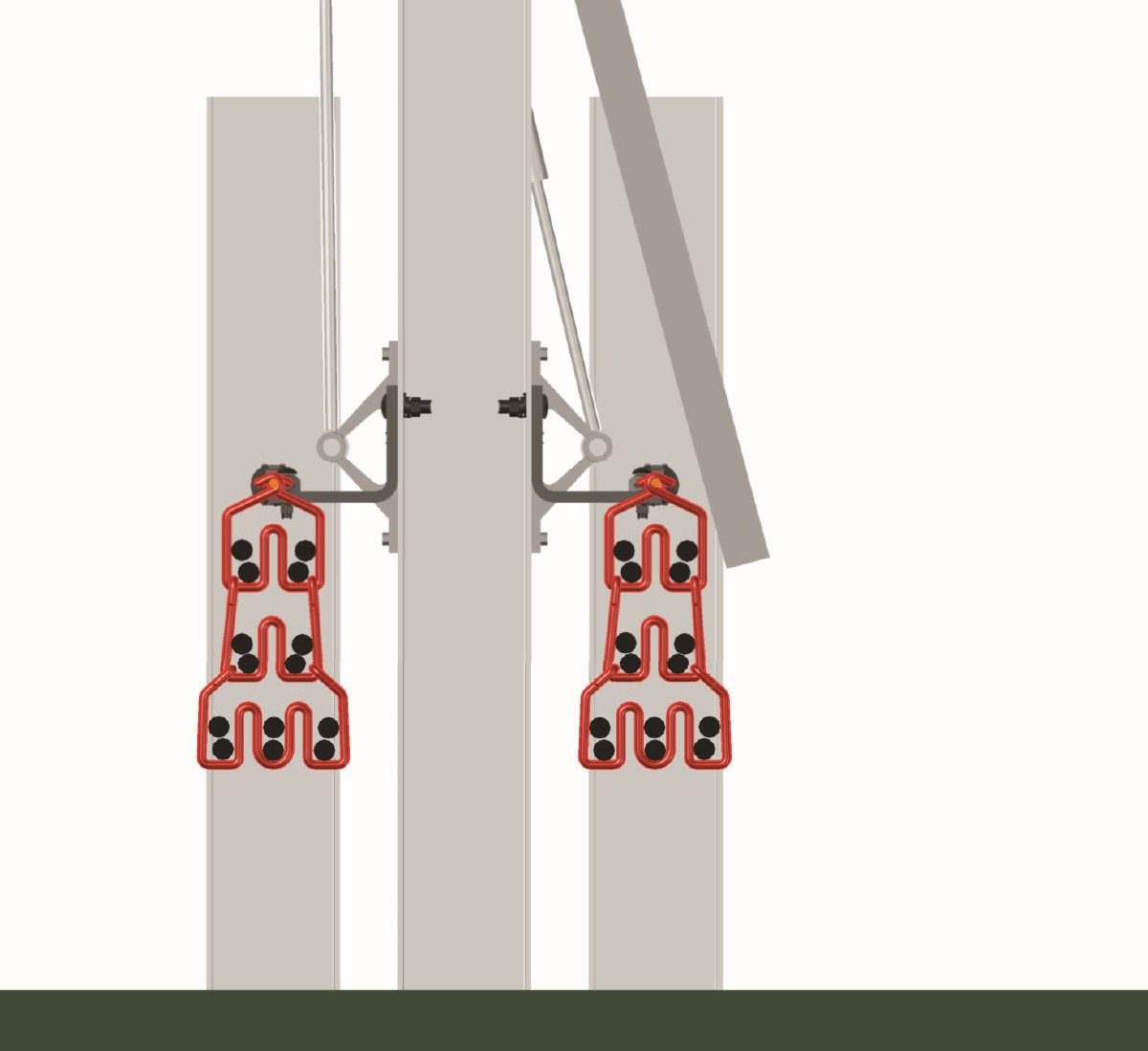

Terrasmart’s screw extensions and adjustable legs integrate seamlessly with its fixed racks and trackers, offering up to 36 inches of adjustability to accommodate uneven terrain. Once the foundations were set, Phoenix Solar took over installation of the screw extensions, legs, torque tube, rails, and modules, with Terrasmart providing ongoing technical support and racking supply.

Why TerraTrak 1P

Building on its partnership with Terrasmart, Nexamp chose the new 1P tracker for its proven reliability and design efficiency. Sharing 80% of its components with the TerraTrak 2P, the one-portrait configuration is foundation-agnostic and pairs easily with adjustable legs for maximum flexibility.

The 1P tracker’s lower height was particularly advantageous in New York, where systems above certain thresholds require more stringent permitting. The compact design reduced visual impact and simplified the approval process.

Its low profile also enhanced safety and installation speed. Because the system could be assembled from the ground, crews didn’t need ladders. This is a major benefit given that ladder-related accidents cause 5,000 injuries annually in construction. With only six hours of daylight during winter, the reduced need for two-person ladder crews helped Nexamp maintain momentum and meet tight deadlines.

TerraTrak’s built-in cable management system further streamlined work. Wiring could be completed from the ground, with integrated cable channels eliminating the need for drip loops and simplifying the layout.

These innovations translated directly into performance.

We were able to install 2,112 panels in one day and that’s an incredible figure. The main contributing factor for this speed is TerraTrak’s 1P low profile and accessibility from the ground. Our installers could handle a panel themselves, hang it on the system, bolt it and quickly move on. Not needing ladders increased safety and kept the team fully engaged in handling wires, bolts, racking and modules, all while reducing labor hours,” Kyle Moore, Assistant Project Manager for Nexamp.

Comments are closed here.