Profiling Zodiac, a ‘substring inverter’ that could revolutionize PV systems

Solar module manufacturing has been in the spotlight in the United States the last few years, mostly in terms of supply chain for conventional PV components. At the same time, reports of underperformance and failure / safety issues continue to mount. Massive solar fields are not hitting their targets; a majority of commercial rooftops are plagued by product failures and workmanship errors.

Instead of investing so much to onshore the status quo of 2025, maybe we should be on the lookout for the next radical innovation in PV technology. Is there any such innovation on the horizon? Maybe!

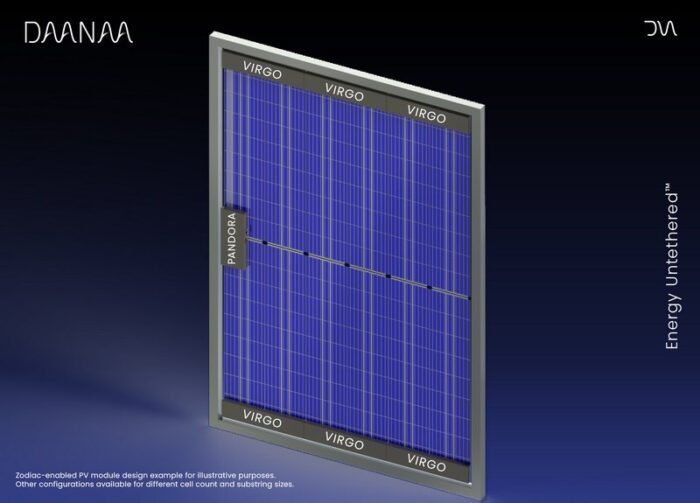

Canadian-born startup Daanaa is promoting a “physics breakthrough” that shapes the “near electromagnetic field in its entirety,” and thus presents an entirely new approach to PV topology and power electronics. This breakthrough is embedded into the PV module, as a “substring inverter system” they are calling Zodiac.

Zodiac would make external module-level power electronics (MLPE) obsolete by embedding DC optimization, inversion, rapid shutdown, and diagnostic functions into power electronic modules at the cell-level.

“The solar industry has long faced challenges with power losses and system complexity due to PV cells’ series connections and external power electronics dependencies,” said Udi Daon, CEO of Daanaa. “Zodiac addresses these issues by embedding multiple functionalities at the PV module’s substring level.”

Zodiac is based on Daanaa’s PTU (power transaction unit) technology that performs multiple power electronics functions with a single step programmable power electronics module to (1) optimize DC, (2) manage voltage conversion across various ranges, and (3) efficiently convert AC, among other functions. The PTU’s built-in data layer enables energy data management, system monitoring, and diagnostics.

It is integrated on the back of the PV panel during the manufacturing process, resulting in a single output, but offers a range of design options based on the desired number of cells per substring (as few as three or as many as 12). The result is PV module that rolls off the assembly line fully optimized — no traditional MLPE components needed — from cell to load.

“All you need to do when it comes out of the manufacturing line is literally plug it in,” Daon tells us.

That’s the theory at least. At Intersolar in San Diego, I saw one solar engineer try to wrap their head around this innovation. Their initial takeaway to me was a “I’ll believe it when I see it,” which is understandable. Let’s take a close look at the Zodiac, its value proposition, and if we’ll actually see PV modules equipped with Daanaa technology.

Conventional solar modules

In traditional PV systems, cells are connected in series, and performance is limited to the lowest performing cell. Minor inconsistencies in cell efficiency, connectivity, or irradiance reduce the energy yield of the entire system.

On top of that, PV systems require matching external power electronics for optimization, inversion, and rapid shutdown, all of which affects system reliability and impacts its performance, while also resulting in complex system design, installation, operations and maintenance.

Zodiac solar modules

Zodiac is comprised of two components: Virgo and Pandora. Virgo connects to solar cells for DC optimization, inversion to high voltage grid AC, rapid shutdown functionality, and substring-level monitoring and diagnostics. Pandora aggregates AC power from the Virgos to deliver a single AC output to the grid. It also serves as a communication interface with external gateways and servers.

Instead of having long strings that can be encumbered by anything, from a leaf to dust to broken cells, Zodiac reduces the impact to as few as three PV cells or six half cuts.

“That eliminates the need for long series connections between cells, and replaces diodes, rapid shutdown, DC optimizers, AC inverters — all of that stuff is inside the PTU,” Daon says.

These substring sections operate independently. The most basic implication of this change is that the PV module’s maximum potential power (and energy harvest) is not limited by the weakest link.

“Any kind of inverter needs a certain level of DC voltage to just turn on. With Zodiac, that input is minimal,” Daon says.

PTU performance

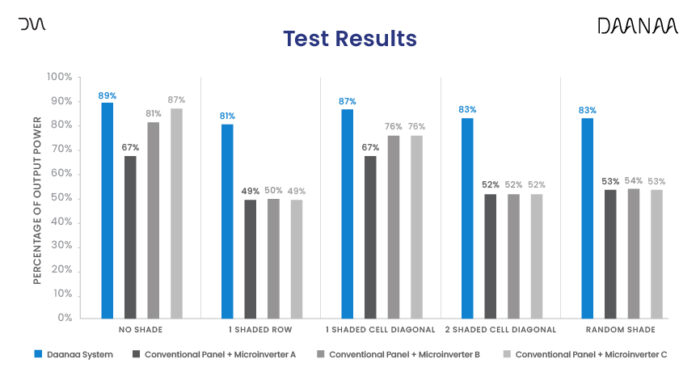

A third-party lab, CFV Labs in New Mexico, tested Daanaa’s beta product against several microinverters and found higher energy yields in every scenario. See Chart 1 for the results.

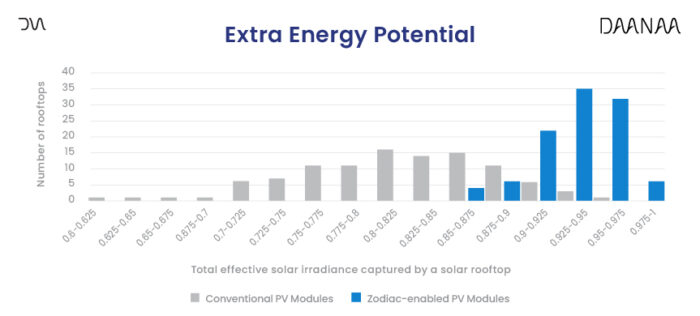

They then analyzed 100 random residential rooftops with those test results. See Chart 2. In this analysis, most rooftops gain an additional 7-17% energy yield when equipped with Daanaa technology, but the potential advantages in higher shading scenarios was significant, ranging from 20% to 27% — with rooftops with extreme shading gaining up to 42% additional energy. The results of this analysis is presented at IEEE PVSC and is available on IEEE Explore. Other benefits would cascade from there…

Eliminating external electronics

Eliminating external power electronics and all of the associated connection points — but still installing a solar module primed to perform all of the functions of traditional MLPE — would mean a simpler installation, fewer points of failure, and lower system costs related to O&M tasks and expenses.

Daon says Zodiac also holds the promise of advanced monitoring and diagnostics at a more granular level than is possible now. “This would mean earlier issue detection and faster resolution.”

“The other financial benefit comes to the installer,”Daon posits. “Right now, installation depends on your least qualified person with a greater opportunity for mistakes and service warranties, etc. Being plug-and-play out of the manufacturing, you minimize that risk dramatically. And from a service perspective, you can know at any given point you can see remotely what’s going on, and you can know why.”

Failure points?

“From a failure point perspective, any failures are localized to those three cells or whatever the number. They’re completely independent,” Daon says. “Even if you shoot some of them out of existence, there is zero impact on rest of them. It’s designed to be disconnected. They’re operating in parallel.”

If a unit does fail, are they field replaceable? “Manufacturers can choose to make it replaceable, though it may not be necessary,” the company tells us. They have been working with installers during their R&D process and are definitely confident on the reliability of their technology, at least compared to solar’s status quo.

Commercialization

Even assuming all of the above exists, any new PV module technology that involves significant changes to existing assembly lines will have a steep uphill climb. Daon believes Zodiac is a fairly simple addition to existing manufacturing lines for any interested PV brands.

“There is some configuration required, but very little in terms of changing the architecture of the production line,” Daon says.

I’m also curious to see if building-integrated PV (BIPV) manufacturers, either solar shingles or facades, jump on Zodiac, because it could solve several of the challenges in that space.

Daon says that a few agreements are in place to integrate Zodiac into PV production lines worldwide for about 500 MW a year capacity. Those announcements could be made by the time you’re reading this.

“The solar power industry won’t be able to support the energy transition with mere incremental changes to the status quo,” Daon says. “Daanaa is here to drive the disruption needed to make it happen.”